REGULAR INSPECTION B-11

6.4 Disassembling/Cleaning the Relief Valve

If the lubricating unit abnormal pressure is caused by a relief valve malfunction, disassemble and

clean the relief valve.

6.4.1 Relief Valve Disassembly

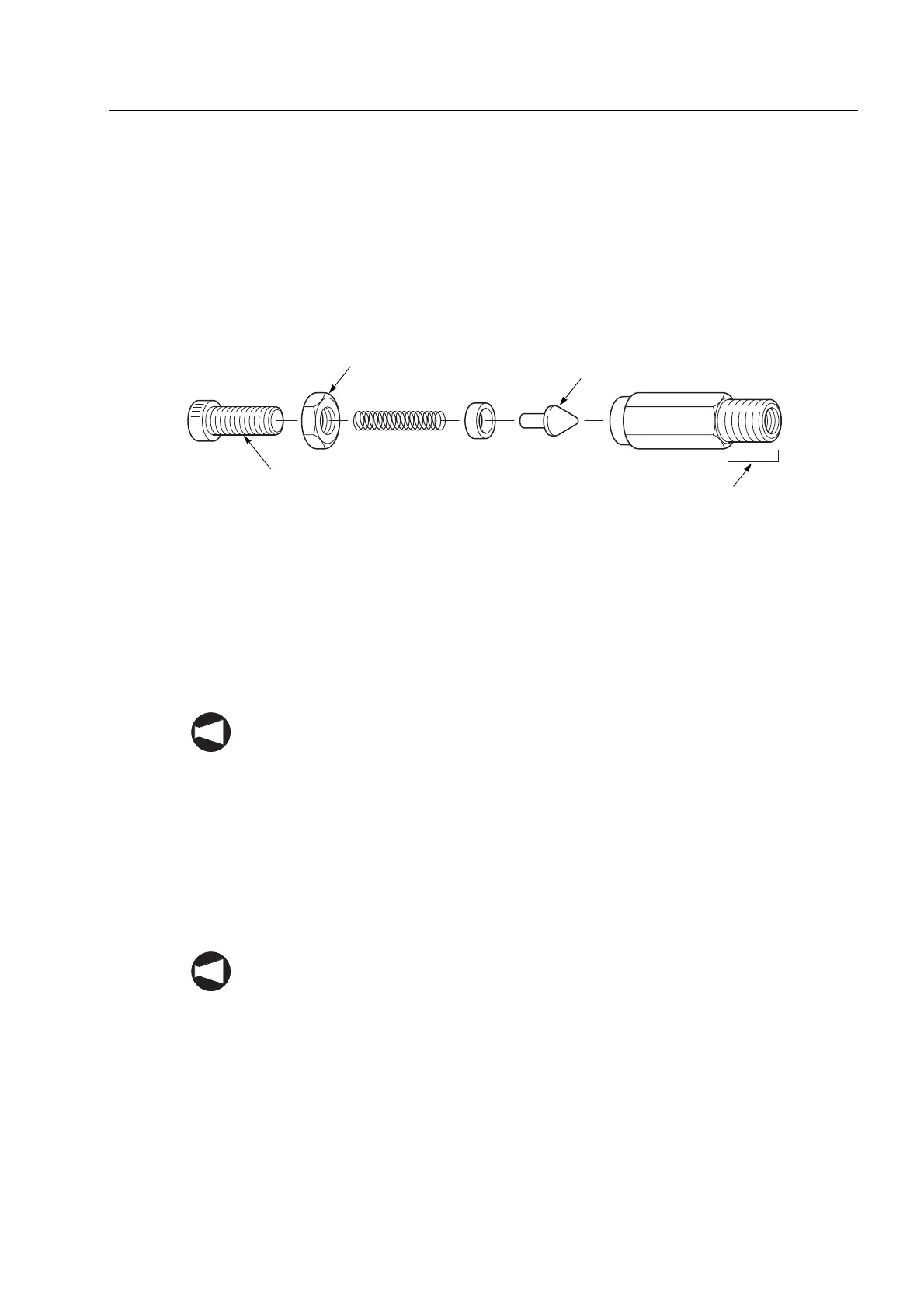

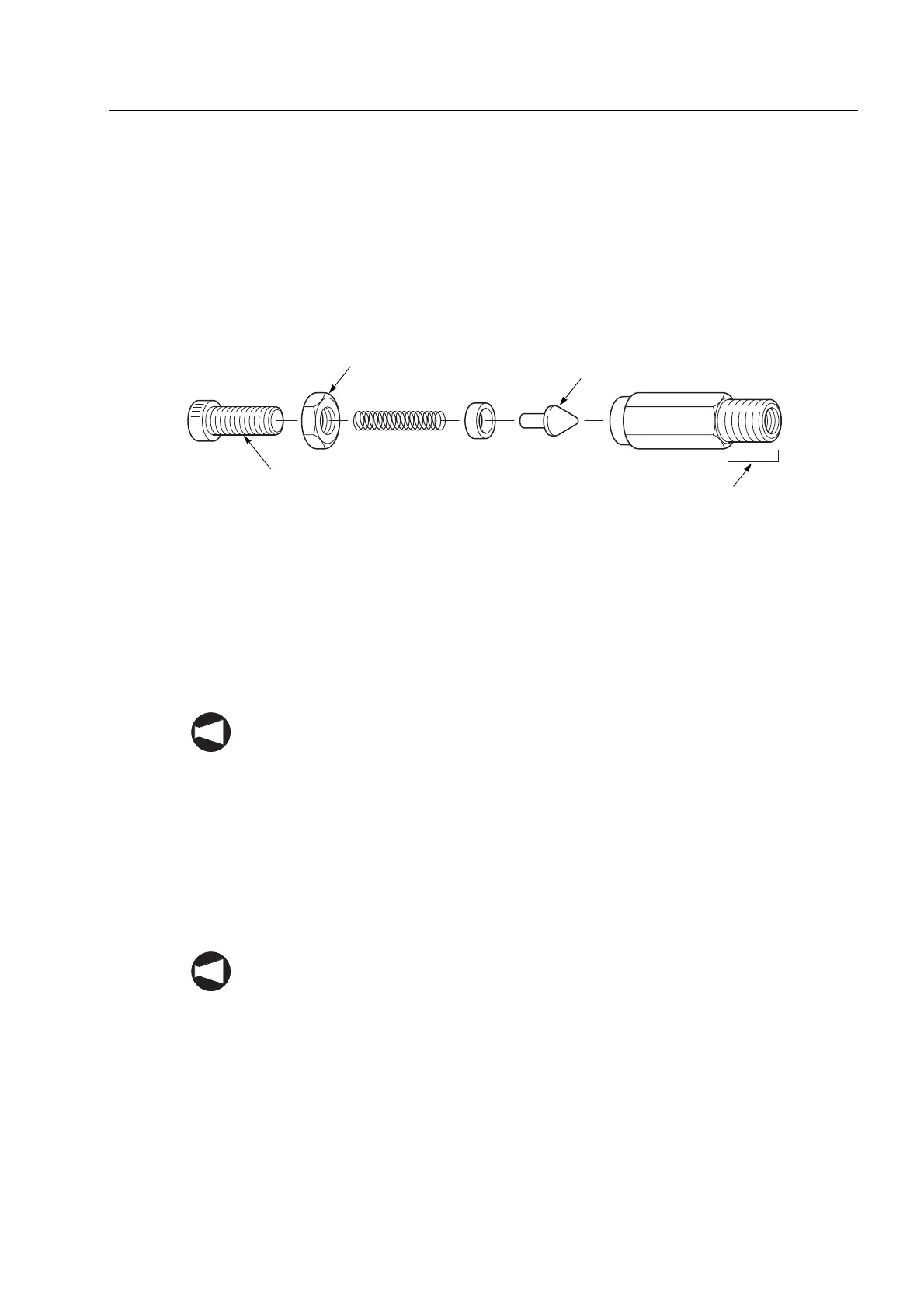

Remove the adjusting screw to disassemble the relief valve as indicated below.

6.4.2 Relief Valve Cleaning

Clean the disassembled relief valve with compressed air and kerosene.

• Take care to check for dust contamination of the tapered section. If scratches are visible on

the tapered section of the relief valve, replacement is necessary.

• Cover the tapered threaded section with seal or sealing tape.

Following disassembly and cleaning of the relief valve, press the manual lubrication button

to bleed air from the piping.

6.4.3 Relief Valve Adjustment

Following disassembly and cleaning, adjustment of the relief valve is required. Bleed air from the

piping properly prior to adjustment.

• Press the manual lubrication button.

• Set the pump discharge pressure to 1.2 MPa using the relief valve adjusting screw.

If unable to set the pressure to 1.2 MPa, the pump is malfunctioning. Contact Mori Seiki

Service Department for assistance.

Lock nut

Valve

Adjusting screw

Tapered threaded section

Relief valve disassembly

NOTE

NOTE

Loading...

Loading...