11

SCYTHING WEEDS. This is cutting by swinging the blade in a level

arc. It can quickly clear areas of field grass and weeds. Scything

should not be used to cut large, tough weeds or woody growths.

NOTE

Do not use a brush blade to cut trees which exceed a diameter of

1/2 to 3/4 inches.

Scything can be done in both directions, or just in one way which

results in the debris being thrown away from you.

That is using the side of the blade that it is rotating away from you.

Tilt down the blade slightly on this same side .You will be hit by

some debris if you scythe in both directions.

Do not force the blade to cut. Do not change the angle of cut after

into the wood. A void using any pressure or leverage which could

cause the blade to bind or crack.

MAINTAINENCE

BLADE

• Sharpen each cutting edge and make sure the inside corner is

rounded to reduce the risk of cracking.

• Do not quench the blade with water if you are using a grinder

as it may start cracks in the blade.

• The 3 tooth blade may be inverted to

utilise a fresh set of cutting edges.

NYLON CUTTERS

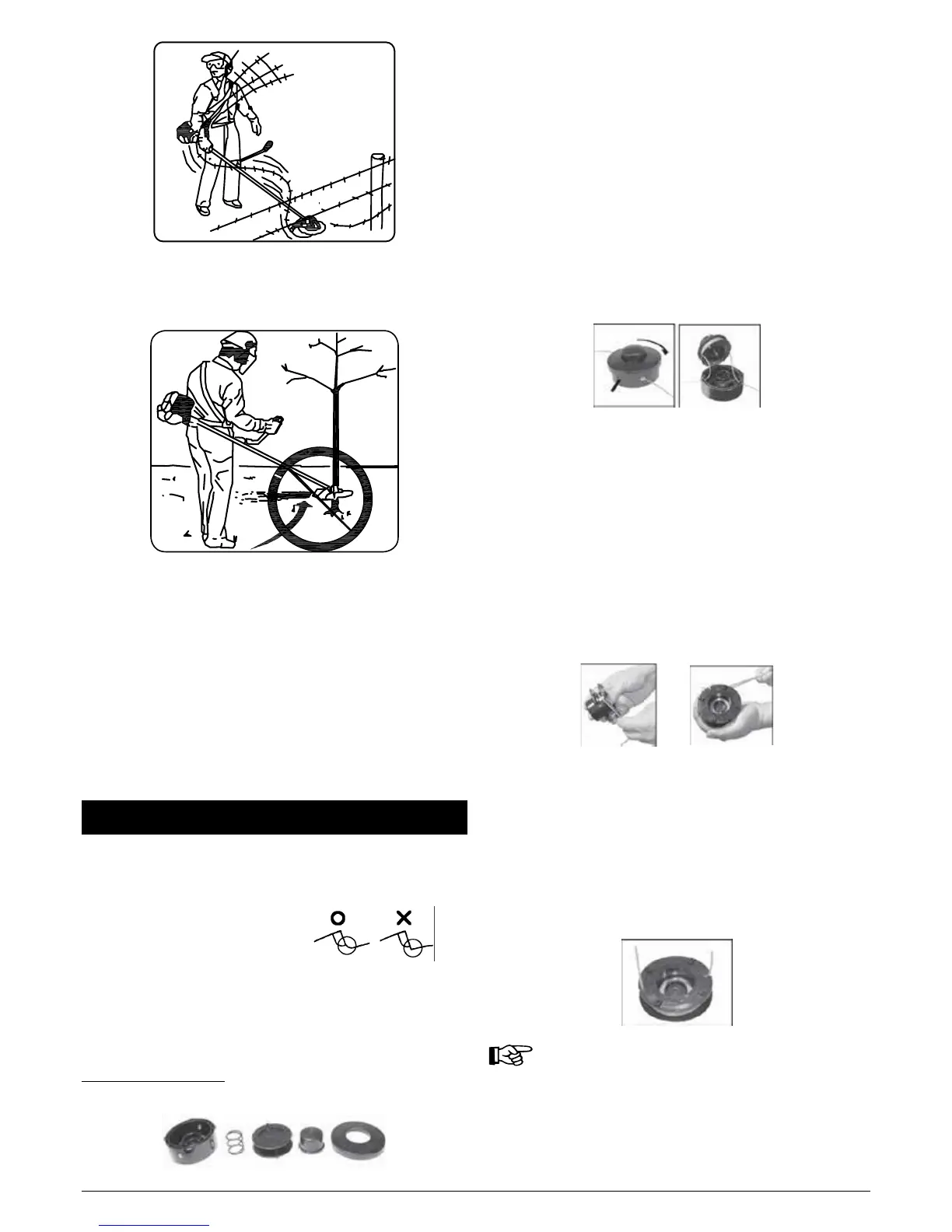

The spools of nylon cord inside these bump-feed cutter heads will

eventually need replacing. While the change can be made with the

cutter head on the machine, it will be more convenient to remove

the cutter head.

CHANGING THE SPOOL

The cutting head consists of the following parts:

• Spool housing

• Spring

• Spool

• “Tap ‘n’ Go” button

• Cover

Push the locking latch located laterally on the spool housing (see

picture, action 1).

Push the locking latch located laterally on the spool housing (see

picture, action 1). Then turn the cover clockwise by about 1.5 cm

(see picture, action 2). This will unlock the cover 5 and it can be

removed. Now remove the Tap’n go button 4 a nd then the used-

up spool 3 from the spool housing. Pass the two line ends of the

new spool th rough the eyelets in the spool housing as shown in

the picture . The line ends still stay clamped in the two transpo rt

clamps pf the spool.

Put the line spool in the spool housing. Please turn the spool such

that the clamped line ends are located directly in front of the eyelets

of the spool housing. Make sure that the spring 2 is properly seated

anunder the spool. Now put the Tap’n go button back on the spool.

Then place the cover onto the 4 guiding pins and lock it in place

by turning it anti-clockwise by about 1.5cm. Now vigorously pull

on both line ends at the same time. This will loosen them from the

transport clamps of the spool. The cutting head is now ready for

operation.

You may also coil up the line yourself. If you do so, use the required

line with a diameter of 2.5 mm only.

Use 2 separate lines with a length of about 2.1m each.To Þx the

line ends the spool has 2 eyelets. Put the end of each thread into

an eyelet. Put the line into the eyelet in the direction of the arrow

as shown on the bottom side of the spool. Put each line end in by

about 2cm. Now grab both lines with one hand and concurrently

coil them up in the direction of the arrow.

Finally, fix the line ends by putting each in one of the transport

clamps as shown in the picture. The spool can now be installed.

Proceed as described above to install the spool.

NOTE:

Both nylon cords need to be wound in the same direction

Loading...

Loading...