8

3. Stop the engine and allow it cool before refuelling the unit.

4. Keep open flames away from the area where fuel is handled or

stored.

E

FUEL

FLAMMABLE

FUEL

5. Use only oil intended for 2 stroke air

cooled engine use. Other oils can

cause spark plug fouling, exhaust

port blocking, or piston ring sticking.

6. Fuel mixtures which have been left unused for

an extended period may clog the carburettor or cause hard

starting. Store unused fuel in an air-tight container in a cool

place.

7. Mix a regular grade petrol (leaded or unleaded) and a good

quality two stroke engine oil for air cooled engines. Shake them

together in a clean container to ensure thorough mixing before

pouring into the fuel tank. Do not use plastic containers not

specifically designed for use with petrol.

8. Mixing ratio chart

Unleaded

Gasoline

2 cycle

mineral oil

25:1

2 cycle semi-

synthetic oil

40:1

2 cycle

synthetic oil

50:1

1 L 40mL 25mL 20mL

4 L 160mL 100mL 80mL

5 L

200mL 125mL

100mL

10 L 400mL 250mL 200mL

OPERATING

STARTING THE ENGINE

Before starting the engine, inspect the entire unit for loose fittings or

fuel leaks, and verify that the cutting attachment is properly installed

and securely fastened.

Place the unit on a flat, firm place. Keep

the cutting head clear of any obstructions.

1. Check that there is fuel in the tank

and that the fuel cap is screwed on

tightly.

(1) Cap

(2) Fuel tank

2. When starting a cold engine move

the choke lever (behind the air cleaner cover) to the closed

position.

(1) Choke lever

(2) Closed

(3) Open

Diagram .B

3. If the engine has been running and is still warm, move the

choke lever to the open position.

4. Press the priming bulb under the carburettor repeatedly until

excess fuel can be seen returning to the tank through the clear

fuel return pipe.

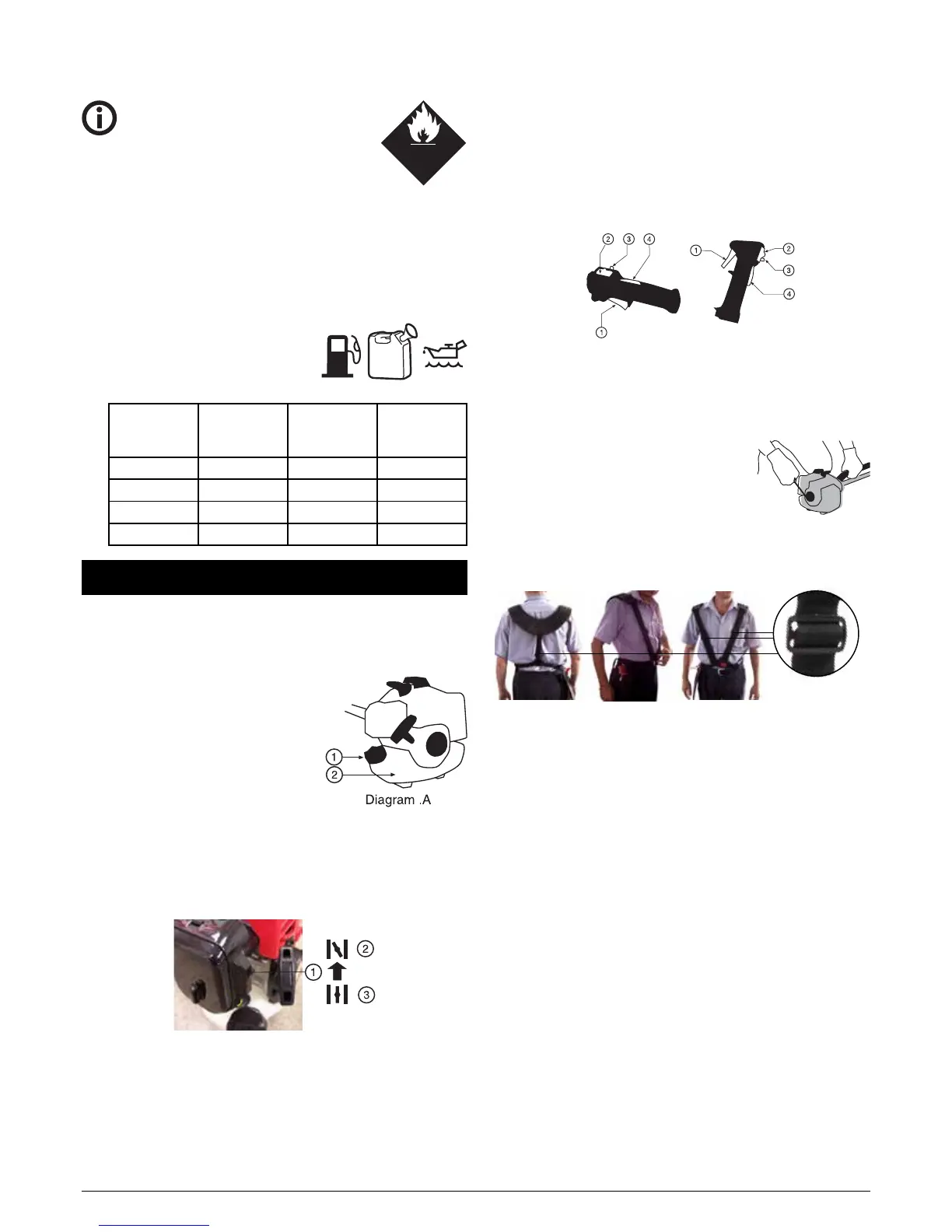

5. Slide the ignition switch (3) on the trigger grip away from the

STOP position (See Diagram .C on the next column).

6. To set the throttle in the start position.

- Depress the safety lever (4)

- Squeeze the throttle lever (1) fully.Hold down the starting

button (3) while releasing the throttle lever.

- The throttle lever will be held partly open until it is squeezed

again.

(1) Throttle lever

(2) Ignition Switch

(3) Starting button.

(4) Safety Lever

Diagram .C

7. While holding the unit firmly, pull out the starter rope quickly.

8. After the engine has started, open the choke gradually.

9. Allow the engine to run for 2 to 3 minutes to warm up before

starting work.

STOPPING THE ENGINE

1. Release the throttle lever.

2. Slide the ignition switch on the trigger grip

to the STOP position.

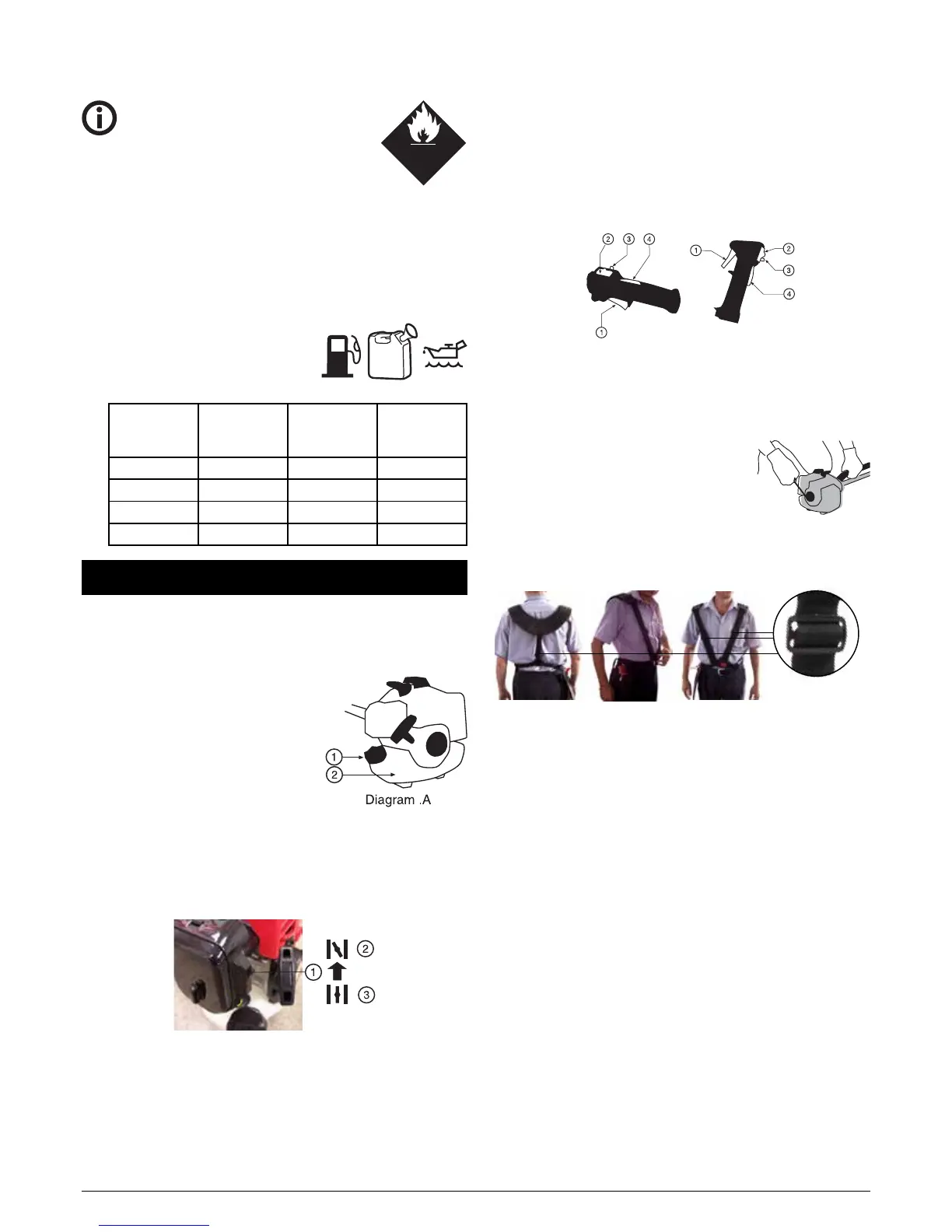

FITTING THE HARNESS

The harness must always be used as the machine cannot be

operated safely without it.

Adjustable

Belt Clip

1. Fit the horseshoe shaped plastic shoulder pad around your

neck (open end of pad facing forward), and slide your arms

through the side loops. The small rectangular belt cushion will

be at your left side and the larger pad and hook clip will be on

your right.

2. Adjust the various belt clips as necessary and fasten the buckle

across your waist.

3. Before starting the engine for the first time, try hooking the

hook clip into the various holes in the hanger along the top of

the main tube to find out which hole gives the best machine

balance.

4. Adjust the length of the strap holding the hook clip to achieve

the correct angle between the ground and the cutting head.

Note that the entire main tube of the machine can rotate to

help achieve the correct cutting posture.

5. Unhook the clip before starting the engine.

Loading...

Loading...