10

Mortonr Water Softener Installation & Operation Manual

INSTALLATION STEPS, continued

" If making a soldered copper installation, do all

sweat soldering before connecting pipes to the

softener fittings. Torch heat will damage plastic

parts.

" When turning threaded pipe fittings onto plastic

fittings, use care not to cross --thread.

" Use pipe joint compound on all external pipe

threads.

" Support inlet and outlet plumbing in some man-

ner (use pipe hangers) to keep the weight off of the

valve fittings.

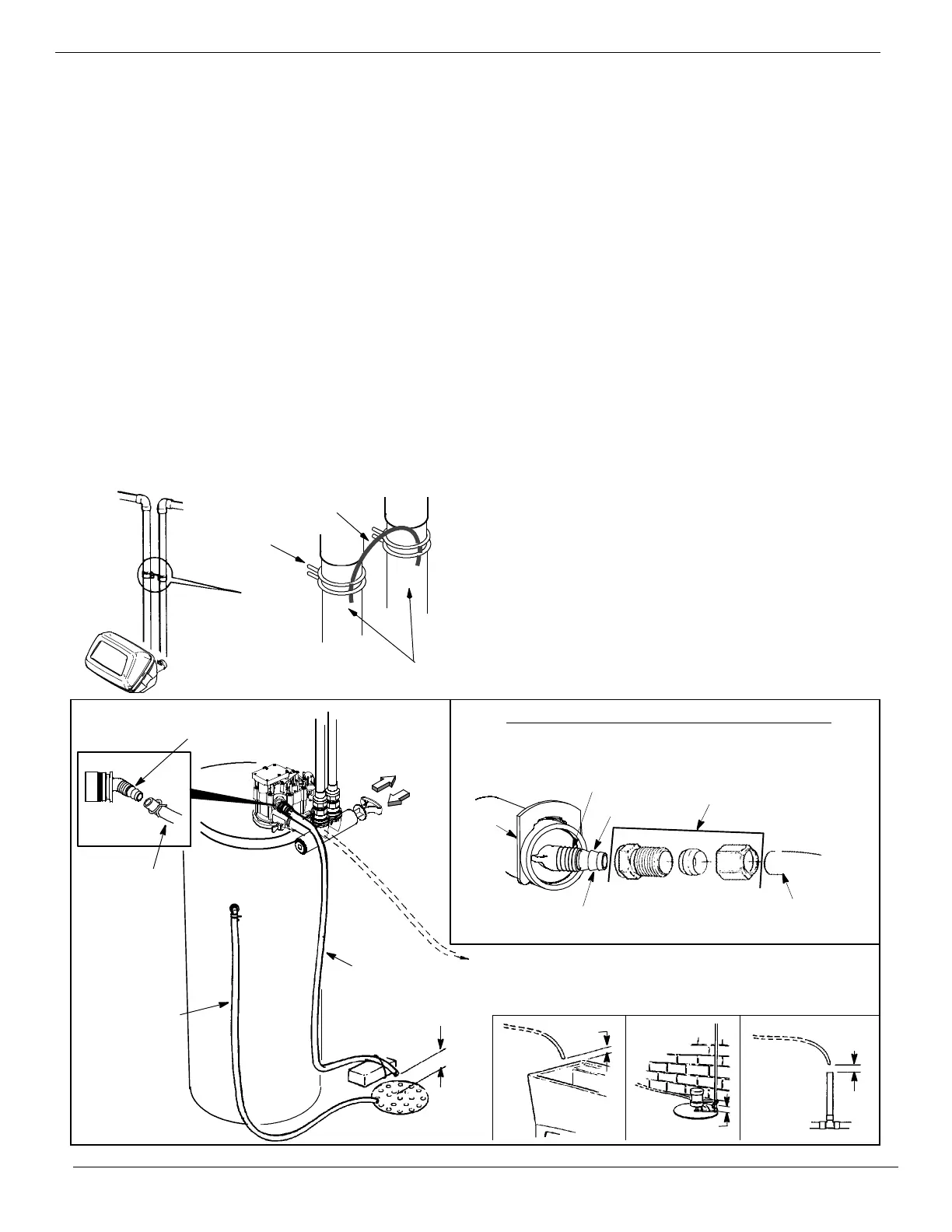

5. INSTALL GROUNDING WIRE (IF NEEDED):

" To maintain electrical ground continuity in the

house cold water piping, install a #4 copper wire

across the removed pipe section, securely clamping

it at both ends (see Figure 2) -- parts not included.

FIGURE 2

ground wire

inlet -- outlet

pipes

hose clamp

ground (2)

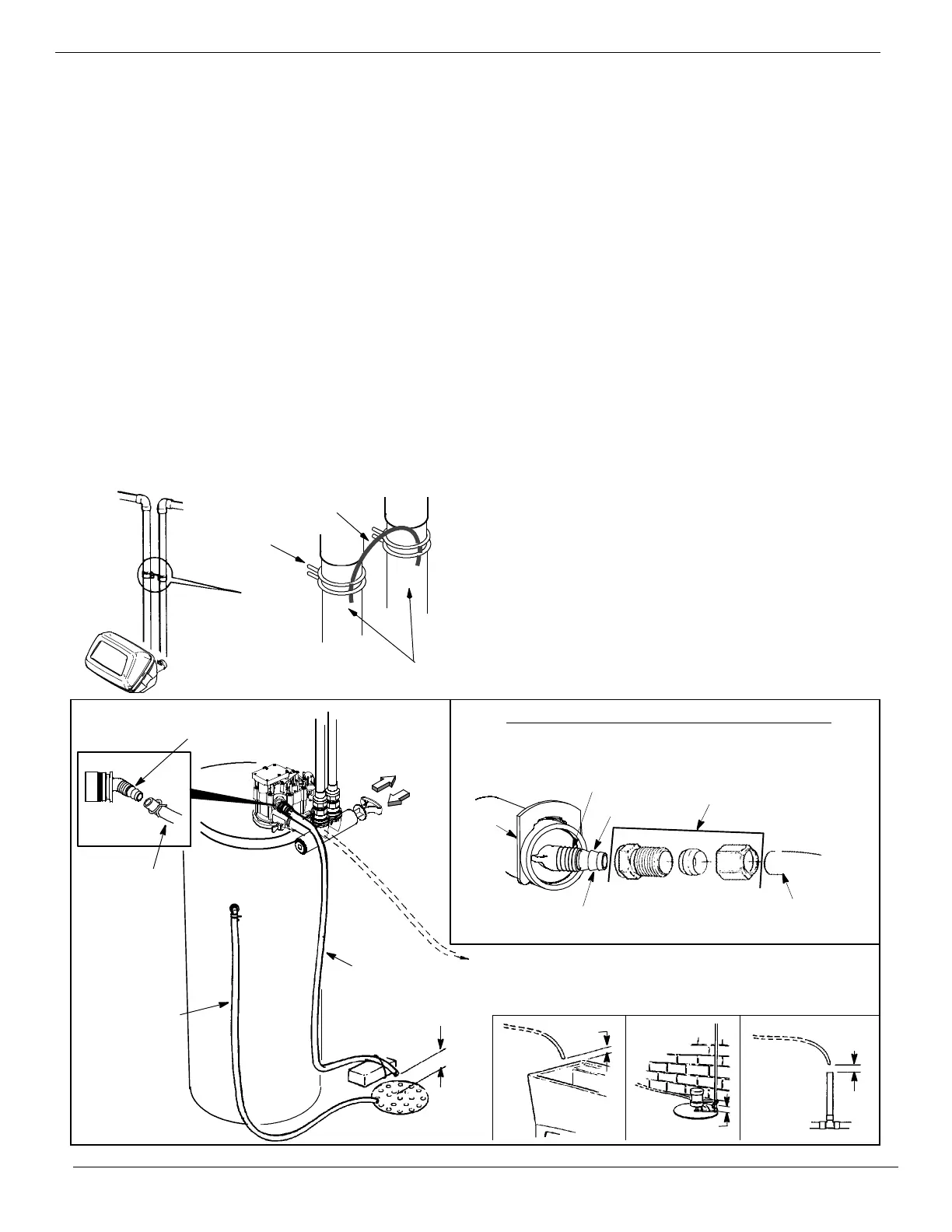

6. CONNECT AND RUN THE VALVE DRAIN

HOSE:

" Measure, cut to length and connect the 3/8” flex-

ible drain hose (provided) to the valve drain fitting.

Use a hose clamp to hold the hose in place.

NOTE: If codes require a rigid drain line, see “Con-

necting a Rigid Valve Drain Tube” in Figure 3.

" Locate the other end of the hose at a suitable

drain point...floor drain, sump, laundry tub, etc.

Check and comply with local codes.

IMPORTANT: If a longer length of hose is needed,

buy and use high quality, thick--wall hose that will

not easily kink or collapse. The water softener will

not work if water cannot exit this hose during regen-

erations.

" Tie or wire the hose in place at the drain point.

Water pressure will cause it to whip during the back-

wash and fast rinse cycles of regeneration. Also pro-

vide an air gap of at least 1--1/2” between the end of

the hose and the drain point. An air gap prevents

possible siphoning of sewer water, into the softener,

if the sewer should back up.

" If raising the drain hose overhead is required to

get to the drain point, do not raise higher than 8’

above the floor. Elevating the hose may cause a

back -- pressure that could reduce brine draw during

regenerations.

continued

CONNECTING A RIGID VALVE DRAIN TUBE

FIGURE 3

STANDPIPE

SUMP

LAUNDRY

TUB

1--1/2”

air gap

1--1/2”

air gap

1--1/2” air gap

To adapt a copper drain tube to the softener, buy a compression fit-

ting (1/4 NPT x 1/2”O.D. minimum tube) and needed tubing from

your local hardware store.

1/4” NPT thread

barbs

1/2” outside diameter

copper tube

Clip

Cut barbs from valve drain elbow (pull clip

and remove drain valve elbow from valve)

Compression fitting 1/4 NPT x

1/2” O.D. tube

To standpipe, sump,

laundry tub or other

approved drain.

valve drain

hose

drain fitting

adaptor

PUSH IN

for bypass

PULL OUT

for soft water

‘‘service’’

1--1/2”

air gap

FLOOR DRAIN

overflow

drain hose

valve drain

hose

Loading...

Loading...