CSD Series Variable Frequency AC Drive

MOTORTRONICS

- 50 -

Note: A new speed setting or timer setting cannot be inserted into an

ongoing timer and speed function. The priority of the preset speed

signals is as follows: Jog >> Multiple Speed >> Digital Operator. The

jog contact has the highest priority and the digital operator has the

lowest priority.

Vibration Prevention Control

Fn92-94 minimizes the system mechanical vibration that is connected

to the motor.

Fn92 = Vibration prevention times (Units = 2mS) - Factory Setting = 5;

Range = 1 - 100

Determine the vibration cycle and adjust Fn92 to 1/4 of the vibration

cycle to minimize oscillation. To determine the optimum setting for

Fn92 use the following formula:

Fn92 = [Vibration Time(mSEC)/8]

Fn93 = Vibration prevention gain - Factory Setting = 0%; Range = 0 - 100%

Minimizes the magnitude of the mechanical vibration at full load.

Fn94 = Vibration prevention bias - Factory Setting = 0%; Range = 0 - 30%

Minimizes the magnitude of the mechanical vibration at no load.

Fn95 = Reserved

Fn96 = Reserved

Fault Contact Control - Factory Setting for Fn97 & Fn98 = 0000

Fn97 - Fn98 define the fault contact on TM2 pins 1 and 2 and what

fault contact the application requires.

Fn97 = XXX0: Fault contact is not energized during auto restart operation

after any fault (excluding OL faults).

XXX1: Fault contact is energized during auto restart operation after

any fault (excluding OL faults).

XX0X: Fault contact is not energized during momentary power loss

detection.

XX1X: Fault contact is energized during momentary power loss

detection.

X0XX: Fault contact is not energized after external emergency stop

signal is received.

X1XX: Fault contact is energized after external emergency stop signal

is received.

0XXX: Fault contact is not energized during external baseblock.

1XXX: Fault contact is energized during external baseblock.

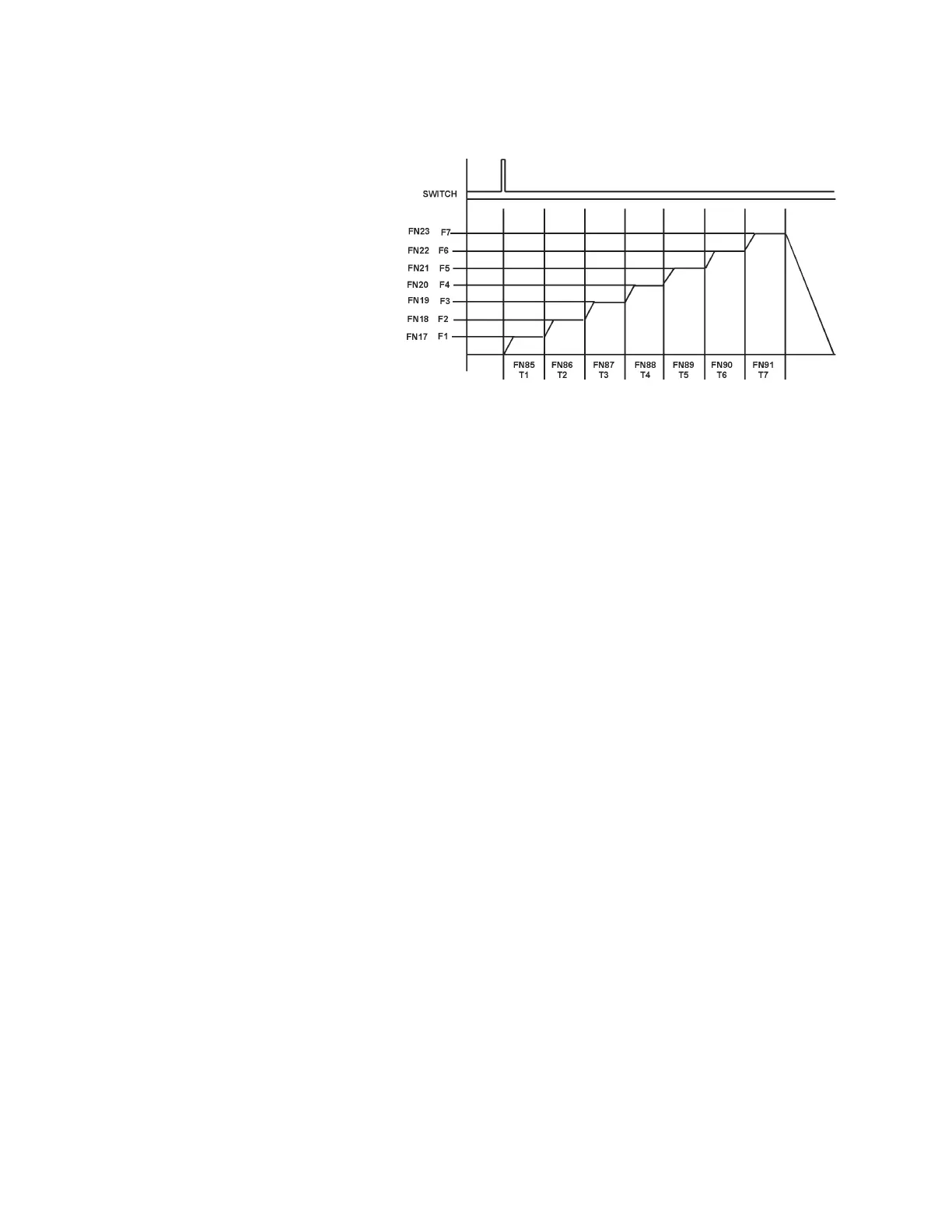

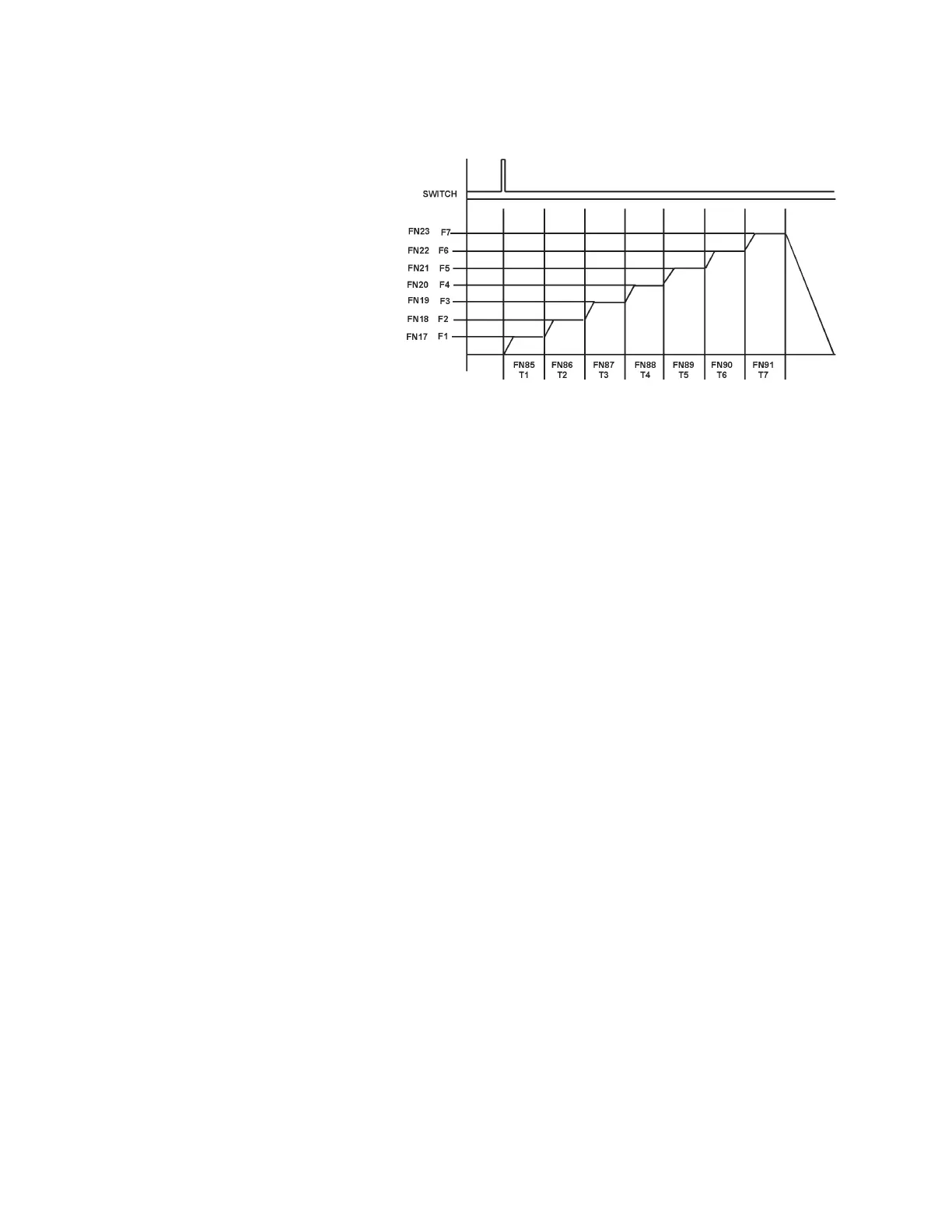

Figure 5 - 10B

2nd Process Time Parameter

Loading...

Loading...