VMX Quick Setup Guide 14 | P a g e

Dual Ramp and Jog Features

TB1 includes provisions for enabling the Dual Ramp and Jog functions by using external contact closures.

Both features use a common +24VDC from Terminal 7 however, they can be used independently of each

other or together. See Section 5.6.2.and 5.6.3 of the Advanced Installation, Operation and Programming

Manual for full function description and setup.

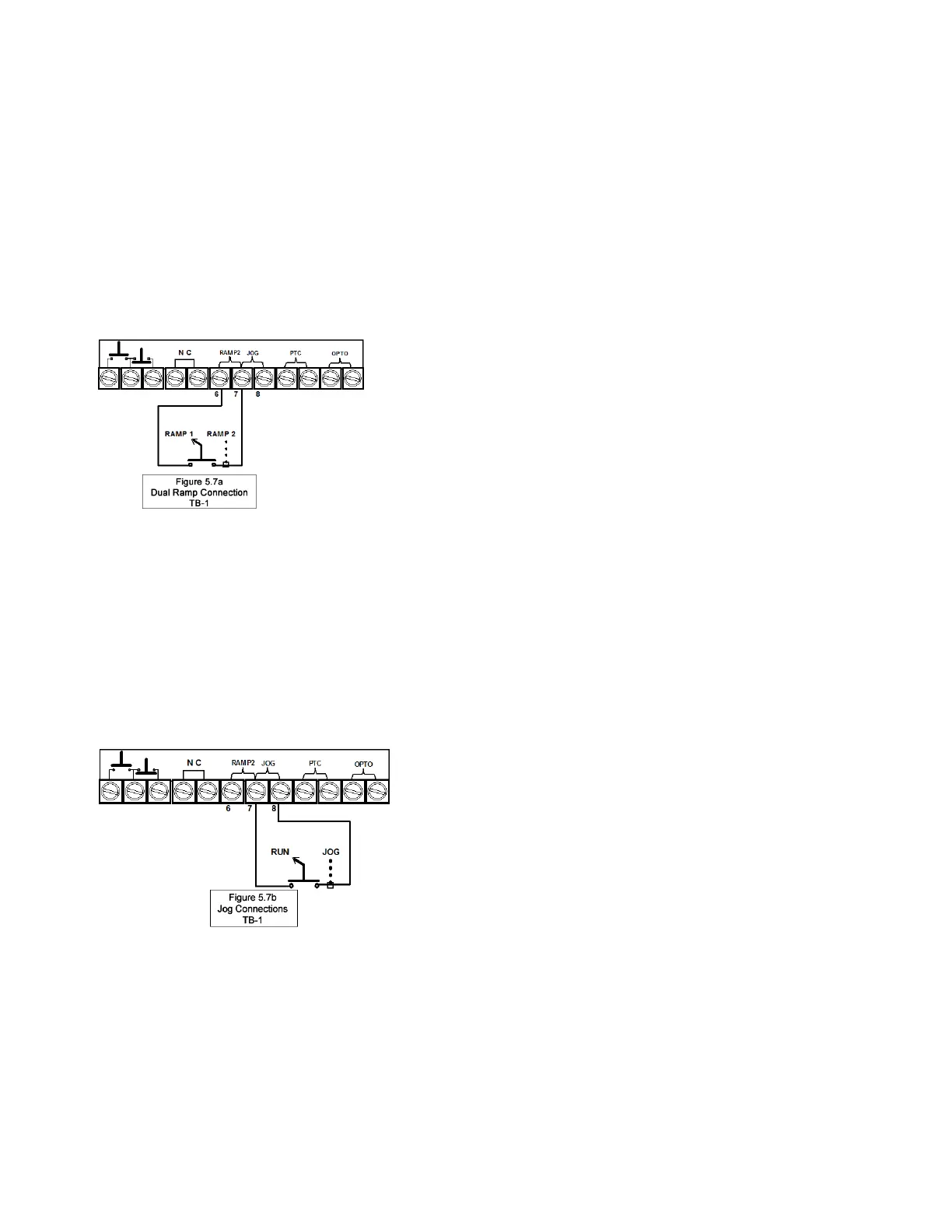

Dual Ramp Command

Closing a dry (voltage free) contact between TB1, terminals 6 and 7 will enable Ramp 2, and the VMX Series

starter will respond to the settings for Ramp 2 in F015 - F018. If no contact closure is present, the VMX

Series starter defaults to the Ramp 1 parameters (F011 – F014).

See Section 5.6.2.of the Advanced Installation, Operation and

Programming Manual for full function description of how to setup the

Dual Ramp Feature.

The Dual Ramp feature is useful in instances where the load

changes significantly. Example: a loaded or unloaded conveyor belt.

The characteristics for starting an unloaded conveyor can be

programmed for ramp 1. The characteristics for starting a loaded

conveyor can be programmed for ramp 2. Ramp 2 can also be

programmed for Full Voltage / Across-the-Line starting by setting the

ramp time to 0 and Current to 600%.

Dual Ramp is also useful in 2-speed motor applications. Simply use an auxiliary contact from one of the

speed contactors to select Ramp 2 so that separate ramp profiles can be used.

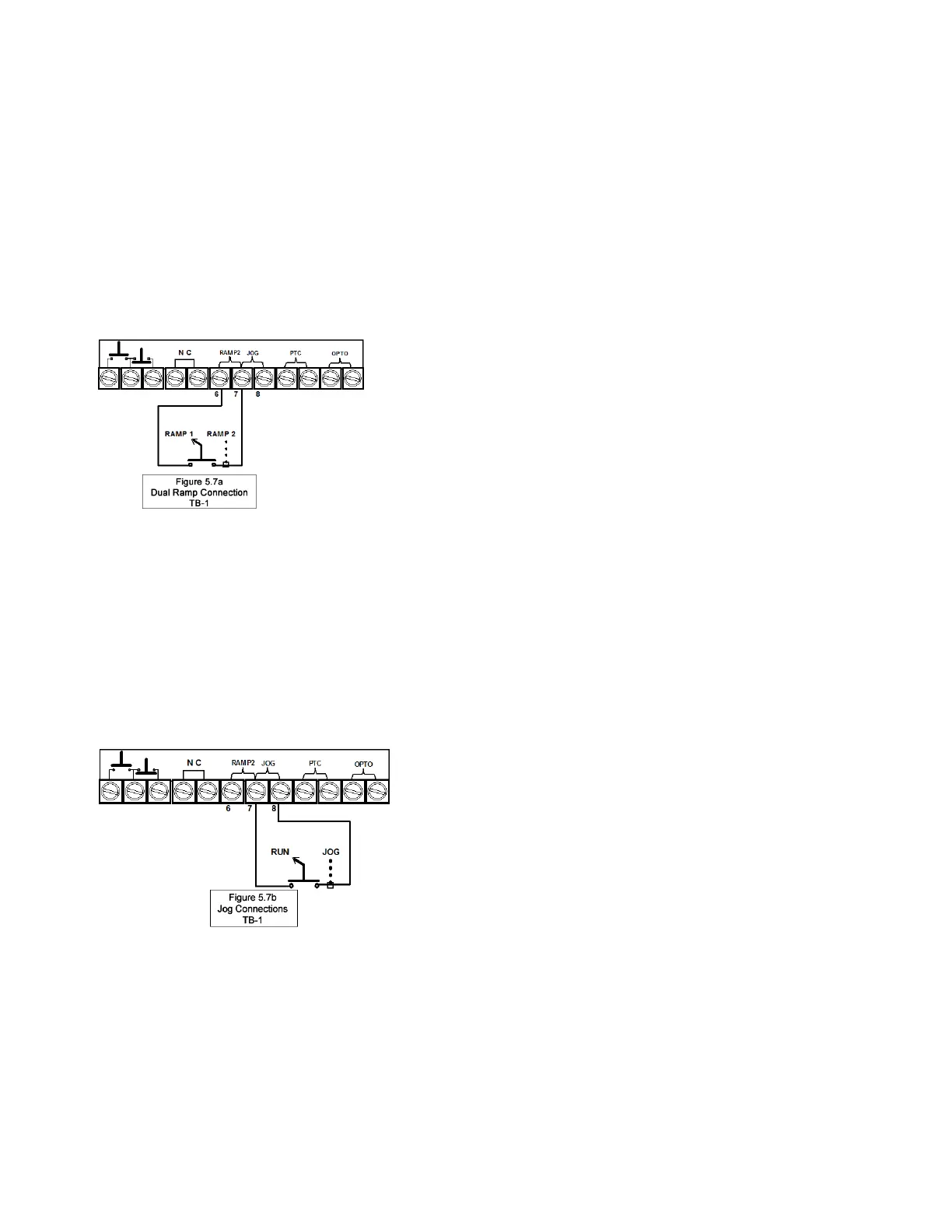

Jog / Remote Command

Connecting a dry (voltage free) contact between TB1, Terminals 7 and 8 will enable the Jog feature. A Start

command (Run Command or Start button) is required to activate the Jog feature. See Section 5.6.3. of the

Advanced Installation, Operation and Programming Manual for

full function description of how to setup of the Jog Function.

The Jog feature can be used for tasks such as lining up

machines for blade or bit changes or inching belts along to check

tracking.

This input is also used to change the function of the Serial

Communications port control through F068. For additional

information, see user manual.

Loading...

Loading...