Functional Safety Installation

ULTIMA X5000 Gas Monitor Safety Manual 9

US

4.4. Proof Test Steps

1. Bypass the safety function and take appropriate action to avoid a false trip.

2. Use HART communications to retrieve any diagnostics and take appropriate action.

3. Send a HART command to the transmitter to set gas reading to the HIGH alarm setting and verify that

the analog current reaches the appropriate value.

4. Send a HART command the transmitter to set gas reading to the LOW alarm setting and verify that the

analog current reaches the appropriate value.

5. Inspect the transmitter for any visible damage or any other communication.

6. Perform sensor calibration per the instructions provided in user manual 10177361.

7. Remove any safety function bypass and restore normal operation.

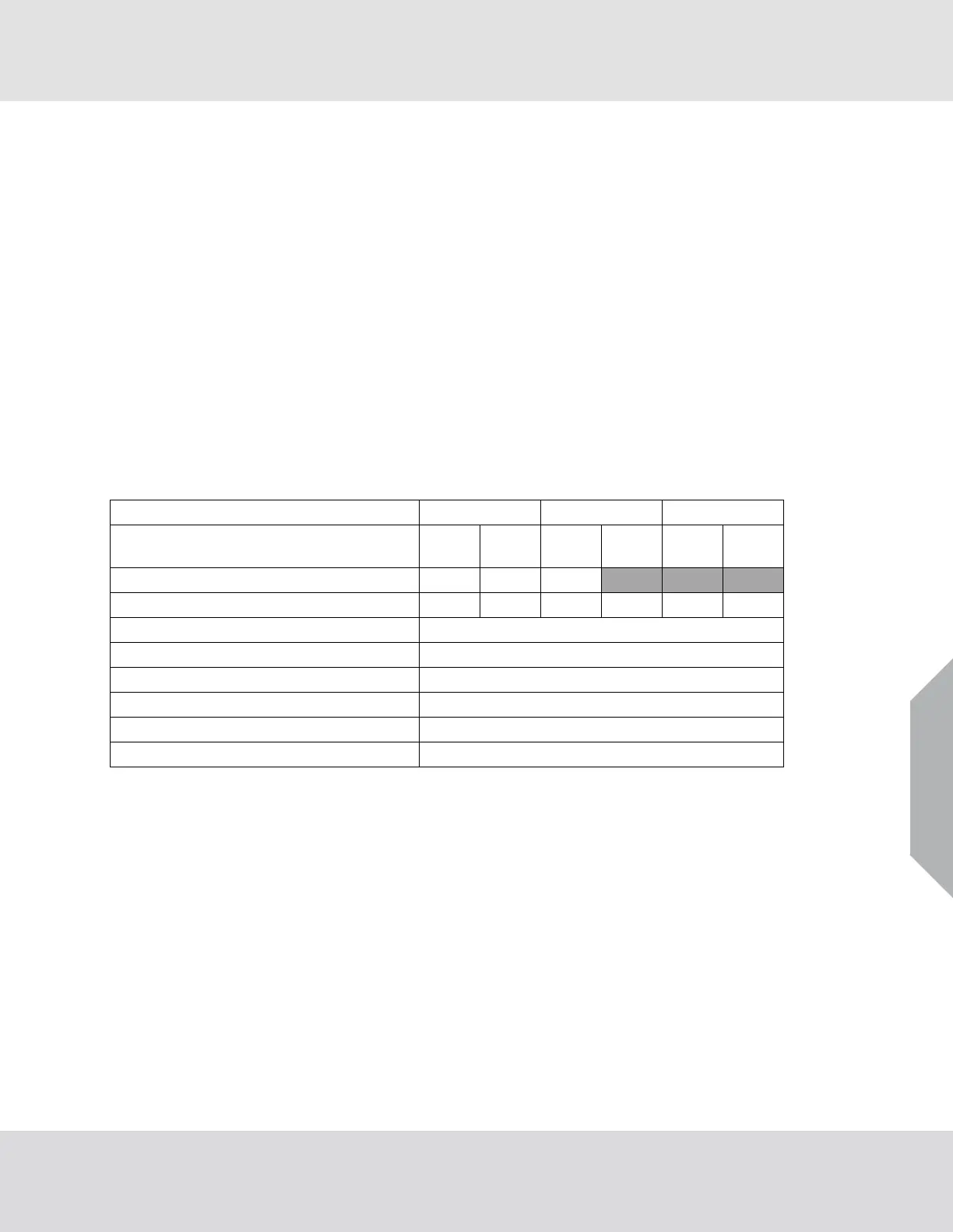

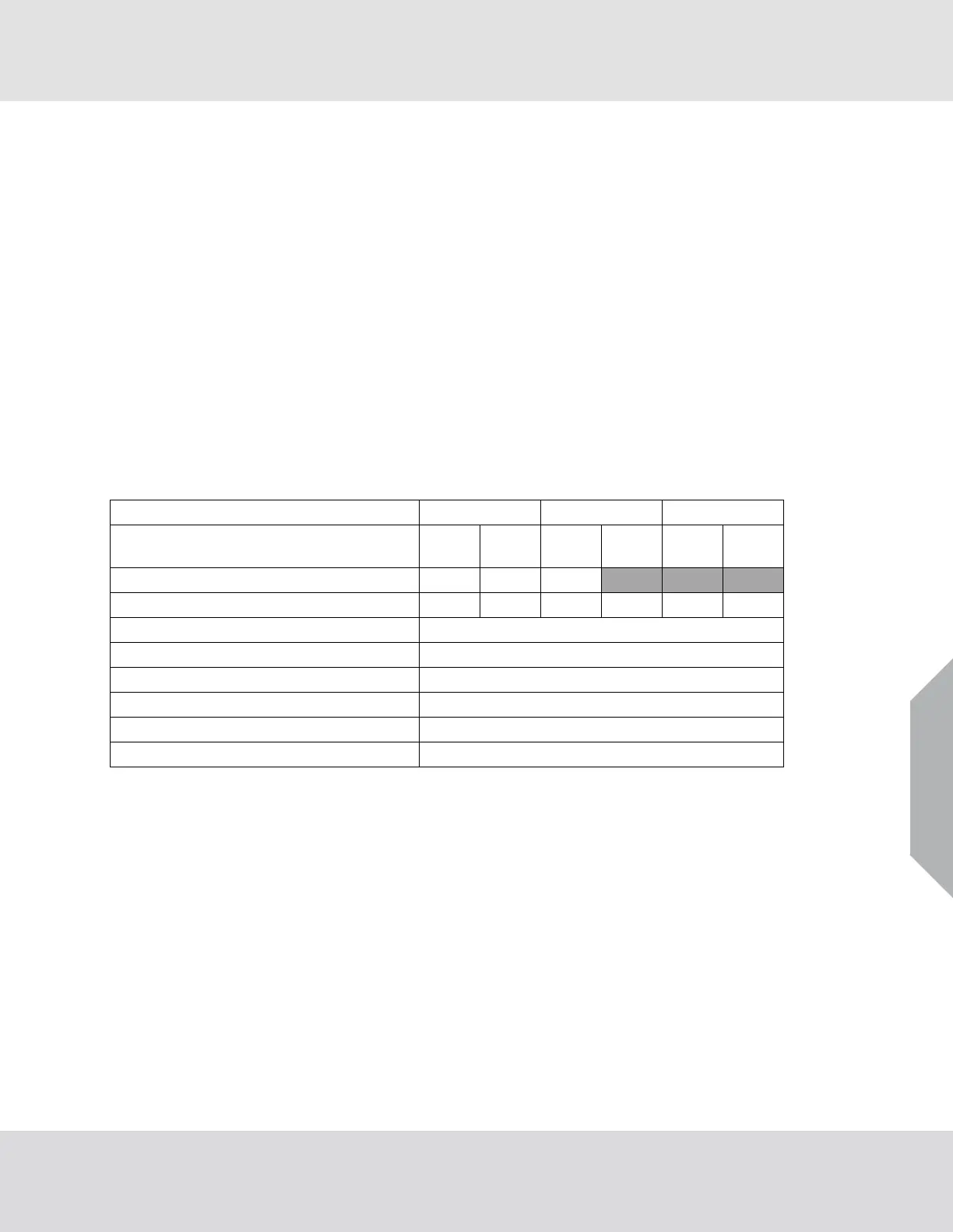

4.5. Safety-relevant Parameters

The X5000 has been subjected to rigorous reliability and functional safety assessments which have

culminated in the device being certified to IEC 61508 (Ed. 2). It is assumed that the field devices will be

installed in a Safety Instrumented System (SIS) in a Low Demand or High Demand environment per

IEC 61508. The following provides the SIL parameters for the Transmitter and Receiver devices:

Safety Integrity Level (SIL)

SIL 1 SIL 2 SIL 3

Low Demand Mode (LDM) / High Demand

Mode (HDM)

LDM HDM LDM HDM LDM HDM

Structure 1oo1

X X X

Structure 1oo2

X X X X X X

λSD, λSU, λDD, λDU

See Table 1

Hardware Fault Tolerance (HFT)

SIL 2 HFT = 0, SIL 3 HFT = 1

Type Classification

B

Mean Time to Restoration (MTTR)

4 hours

Proof Test Interval (PTI)

3 months

Systematic Capability

SC 2

4.6. Application specific restrictions

The following application specific restrictions are applicable to the X5000 and have been considered during

the Failure Modes, Effects and Diagnostic Analysis of the X5000. These restrictions shall be included in the

safety manual for the X5000.

The failure rates for the Xcell sensor sections do not include the sensor failure rates, which must be

added to obtain the complete metrics.

If the relay board option is used the Fault Relay output must be monitored by the logic solver.

Loading...

Loading...