AIR COMPRESSOR MANUAL

- 13 -

7. Maintenance

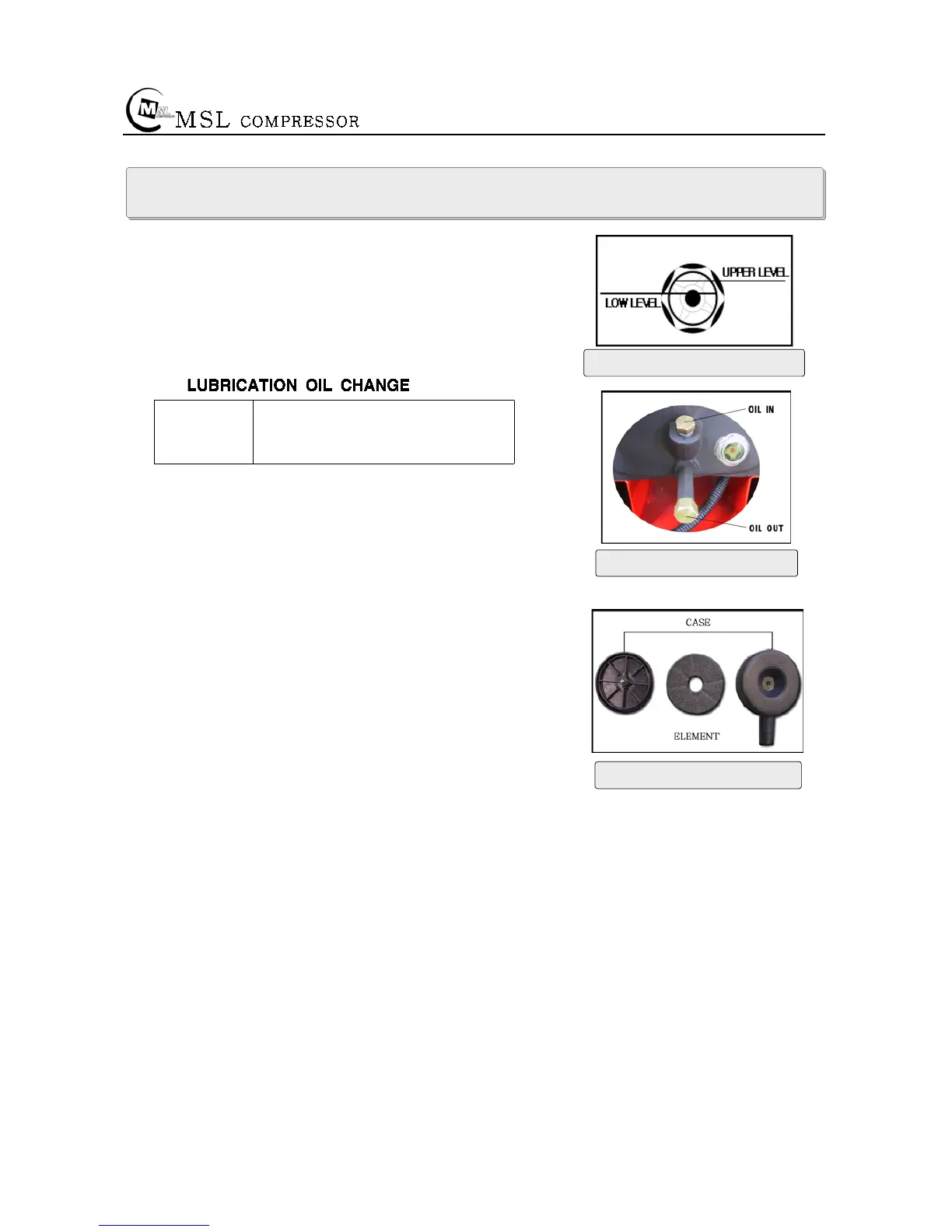

7-1 Checking Oil Level

■ Check the Oil status before starting a

machine.

■ Pour the Oil when it is needed after checking

oil status

◩

OIL TYPE

MSL BREATHING AIR COMPRESSOR OIL

model = 1. MOS100

2. MOS501

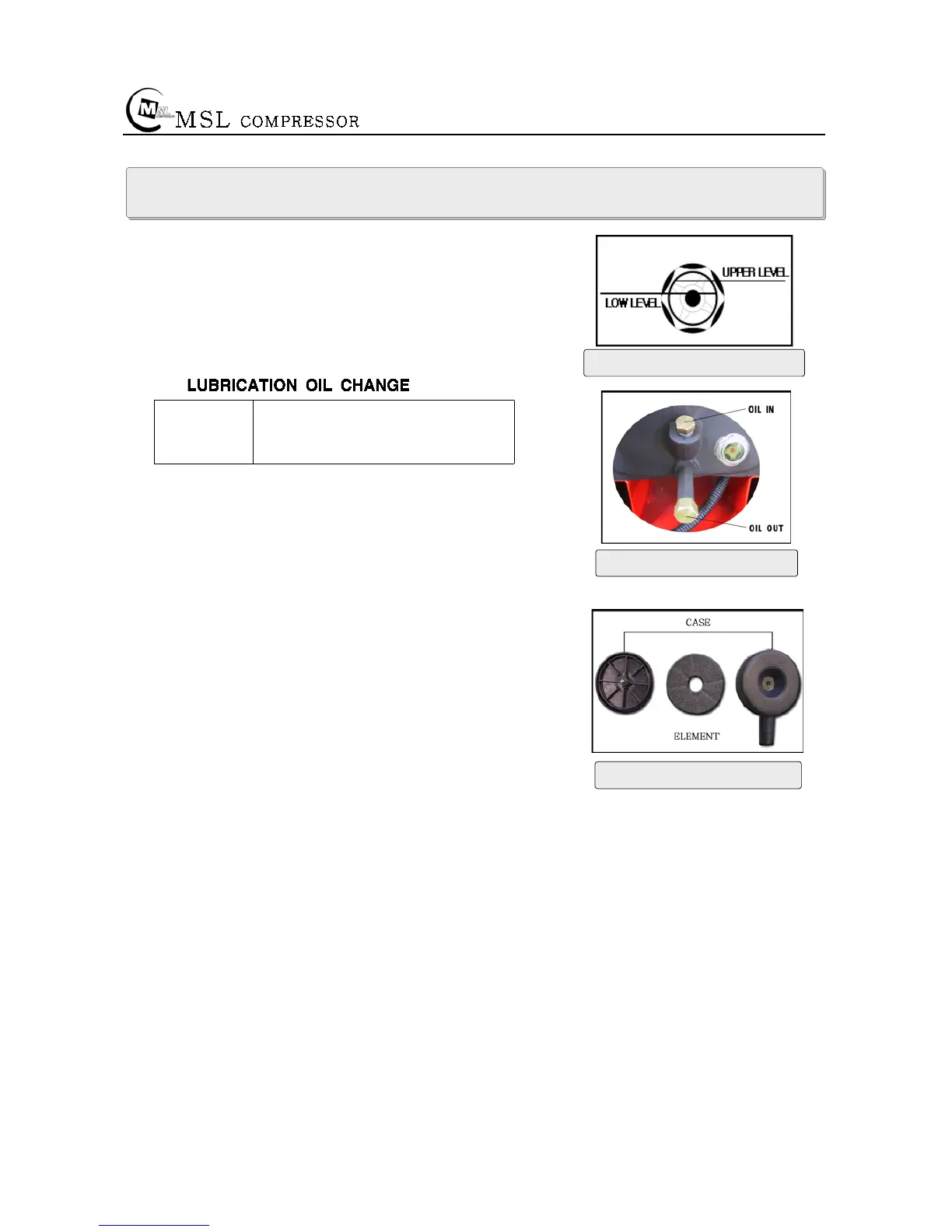

7-2 Air Intake Filter

■ Install the extension hoses from suction filter on

the clean air, if needed.

■ Air inlet filter only for dust reducing of air.

■ Filter element should be exchanged periodically or

when needed.

■ Exchange the ELEMENT when it is impossible to use.

■ Using the soiled filter is not good for performance,

power consumption and durability.

7-3 Cylinder heads and valves

Inlet and outlet valves of the 1st stage are located under the 1st stage valve cover.

The inlet valve opens of the down-stroke, the outlet one on the up-stroke. To reach the

2nd and 3rd stage valves, it is necessary to remove the cylinder heads first. Then the

valves can be pulled out of their seat and held in a bench-vice with the alloy valve holder

for further dismantling. The valves should be replaced after 1000 working hours due to

normal wear and tear.

7-4 Drain Valve

■ Drain

the condensates by opening the drain valve when filling job is finished

■ Auto drain valve is automatically opened when the compressor is stopped.

■ Auto drain valve won't work, on condition of having a some trouble in the

SOLENOID VALVE.

■ Be required spacial attention in winter.

- Be careful of damaging the COMPRESSOR BODY and LINE by the frozen air line.

- Use the hot stove to melt the frozen DRAIN VALVE.

Fig_2 OIL LEVEL GAUGE

Fig.3 OIL CHANGE

Fig.4 SUCTION FILTER

Loading...

Loading...