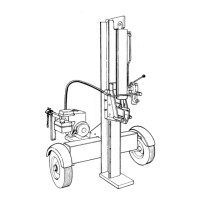

This document is an operator's manual for a log splitter, specifically Model Series 500 thru 510, manufactured by MTD Products Inc. The manual provides comprehensive instructions for assembly, safe operation, maintenance, and troubleshooting of the log splitter.

Function Description:

The log splitter is a power machine designed for splitting wood logs. It utilizes a hydraulic system to push a wedge through a log, splitting it lengthwise. The machine is equipped with an internal combustion engine to power the hydraulic pump. It can be operated in both horizontal and vertical positions, offering flexibility for different log sizes and user preferences. The control handle allows the operator to move the splitting wedge forward (to split wood), to neutral (to stop the wedge), or backward (to return the wedge). A "dislodger" feature is mentioned, which automatically removes lodged wood when the wedge is retracted.

Important Technical Specifications:

- Engine: Internal combustion engine (specific details are referred to in a separate engine manual). It requires gasoline and oil.

- Hydraulic Fluid: Dexron III automatic transmission fluid or 10W AW hydraulic fluid.

- Hydraulic Reservoir Capacity: 3.5 gallons.

- Hydraulic Filter: 10 micron hydraulic filter (Part Number 723-0405).

- Tire Pressure: Maximum 30 p.s.i. (check sidewall for recommended pressure).

- Towing Speed: Do not tow faster than 45 mph.

- Pump: Gear pump (11gpm).

- Cylinder: Hydraulic cylinder.

- Coupling: Flexible pump coupler (nylon "spider" insert) between the pump and engine shaft.

Usage Features:

- Operating Positions: The log splitter can be locked into either a horizontal or vertical operating position. The vertical position is useful for splitting larger or uneven logs, allowing them to lean against the beam for stability.

- Control Handle: A three-position control handle (Forward, Neutral, Reverse) for wedge movement. The reverse position locks the wedge in a disengaged state, and it automatically returns to neutral when the stroke is complete.

- Log Stabilization: Instructions emphasize placing hands on the sides of the log, not the ends, and using wooden shims or split wood for stabilization when splitting extra-large or uneven logs.

- Safety Zones: Operators should always work from specified operator zones, and bystanders, helpers, pets, and children should be kept at least 20 feet away.

- Fueling: Requires extreme care due to gasoline's flammability. Fueling should be done outdoors, with the engine cool and off, and without overfilling.

- Starting: Detailed instructions for starting the engine, including choke and primer usage, and circulating hydraulic fluid in cold weather.

- Towing: The log splitter can be towed, but users must check local, state, and federal vehicle requirements. It attaches to a Class I or higher hitch with a 1-7/8" ball.

Maintenance Features:

- Hydraulic Fluid:

- Check fluid level regularly using the dipstick.

- Change fluid every 100 hours of operation.

- Drain and flush the reservoir and hoses with kerosene when performing repair work on hydraulic components (recommended by an authorized service dealer).

- Prime the pump before initial start-up by turning the engine over with the spark plug disconnected.

- Bleed air from hoses before operating.

- Extend and retract the wedge 12 complete cycles after filling/refilling to remove trapped air.

- Hydraulic Filter: Change every 50 hours of operation.

- Beam and Splitting Wedge:

- Lubricate the beam (where the wedge slides) with engine oil before each use.

- Adjust the wedge assembly bolts to eliminate excessive "play" between the wedge and beam.

- Periodically remove, rotate, or replace the "gibs" (spacers) between the wedge assembly and the back plate for even wear.

- Hose Clamps: Check tightness of suction and return hose clamps regularly.

- Engine: Refer to the separate engine manual for all maintenance instructions.

- Flexible Pump Coupler: Inspect regularly for vibration or noise. Replace if it hardens, deteriorates, or fails, following specific steps for removal and installation, ensuring proper clearance between the nylon "spider" and engine coupling half.

- Tires: Maintain equal pressure in all tires, not exceeding 30 p.s.i.

- General: Periodically check all nuts, bolts, hose clamps, and hydraulic fittings for tightness. Keep safety guards and shields in place. Clean debris and chaff from engine and muffler areas to prevent fires.

- Storage: Clean the unit thoroughly, wipe with an oiled rag, and store in a clean, dry area. Refer to the engine manual for specific engine storage instructions, including draining fuel.

The manual emphasizes numerous safety warnings, including:

- Always read and understand the manual before operation.

- Keep hands and feet away from moving parts and the wedge.

- Never allow children under 14 to operate the machine.

- Maintain a 20-foot safety zone around the machine.

- Be aware of high hydraulic fluid pressures and the danger of fluid penetration injuries.

- Wear safety shoes, safety glasses/goggles, and avoid loose clothing or jewelry.

- Operate on a level surface and block the machine to prevent movement.

- Split wood only, and with the grain.

- Use extreme caution with gasoline due to its flammability.

- Never leave the machine unattended with the engine running.

- Do not operate under the influence of alcohol, drugs, or medication.

- Do not modify the engine governor settings or the machine's structure.

- Be cautious of hot muffler and engine areas.

- Do not adjust pressure relief valve settings.

The product comes with a two-year limited warranty against defects in material and workmanship, provided it's operated and maintained according to the manual. Normal wear parts are covered for 90 days, with extended coverage if failure is due to defects in other components. Log splitter pumps, valves, and cylinders have a separate one-year warranty. The warranty is voided by improper fluid levels, incorrect fluid, unauthorized adjustments to pressure settings, disassembling the pump, improper beam lubrication, incorrect wedge adjustment, overheating the hydraulic system, or unaddressed leaks. The engine and its components are covered by their respective manufacturer's warranties.