Ignition System

97

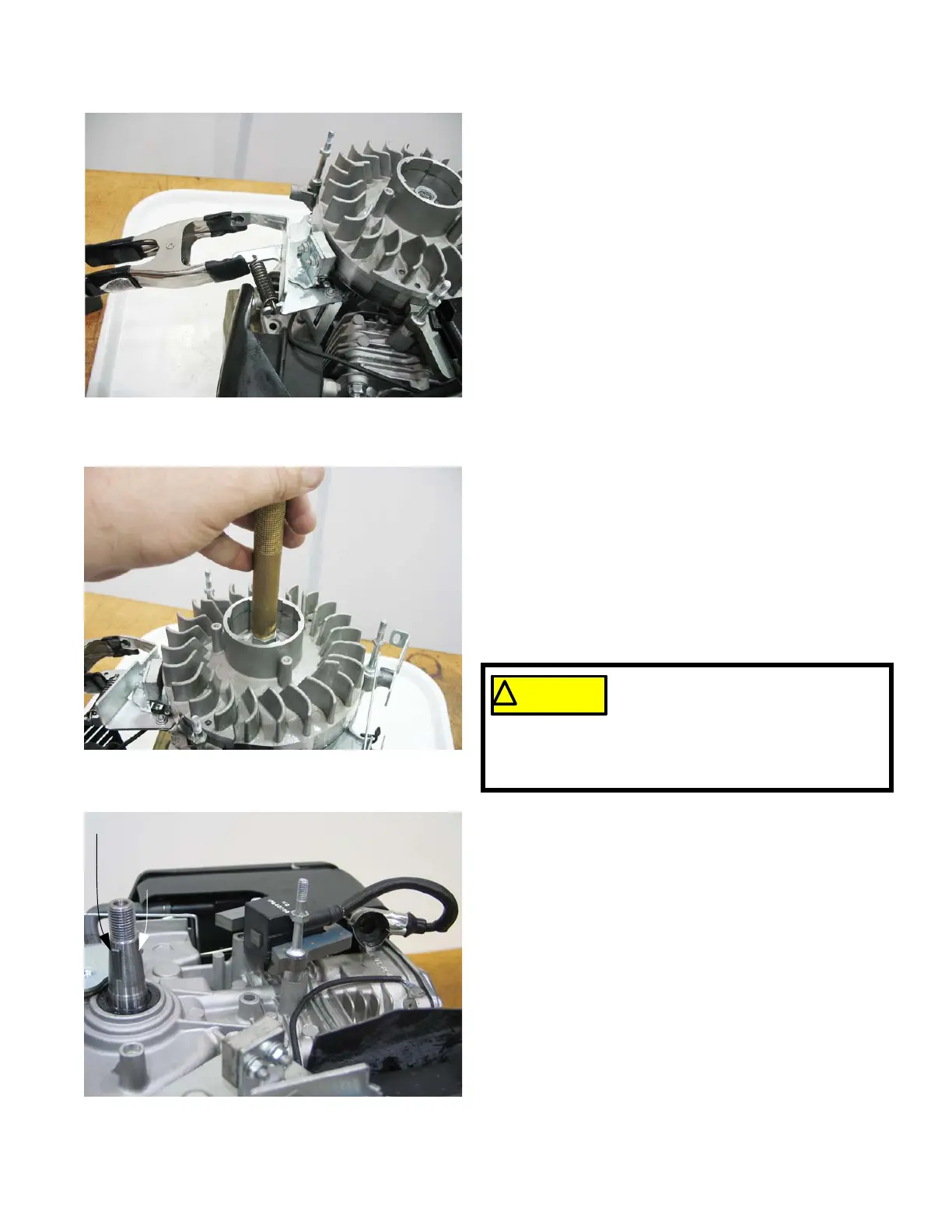

NOTE: If equipped with an engine brake, clamp off the

brake using a spring clamp. See Figure 7.25.

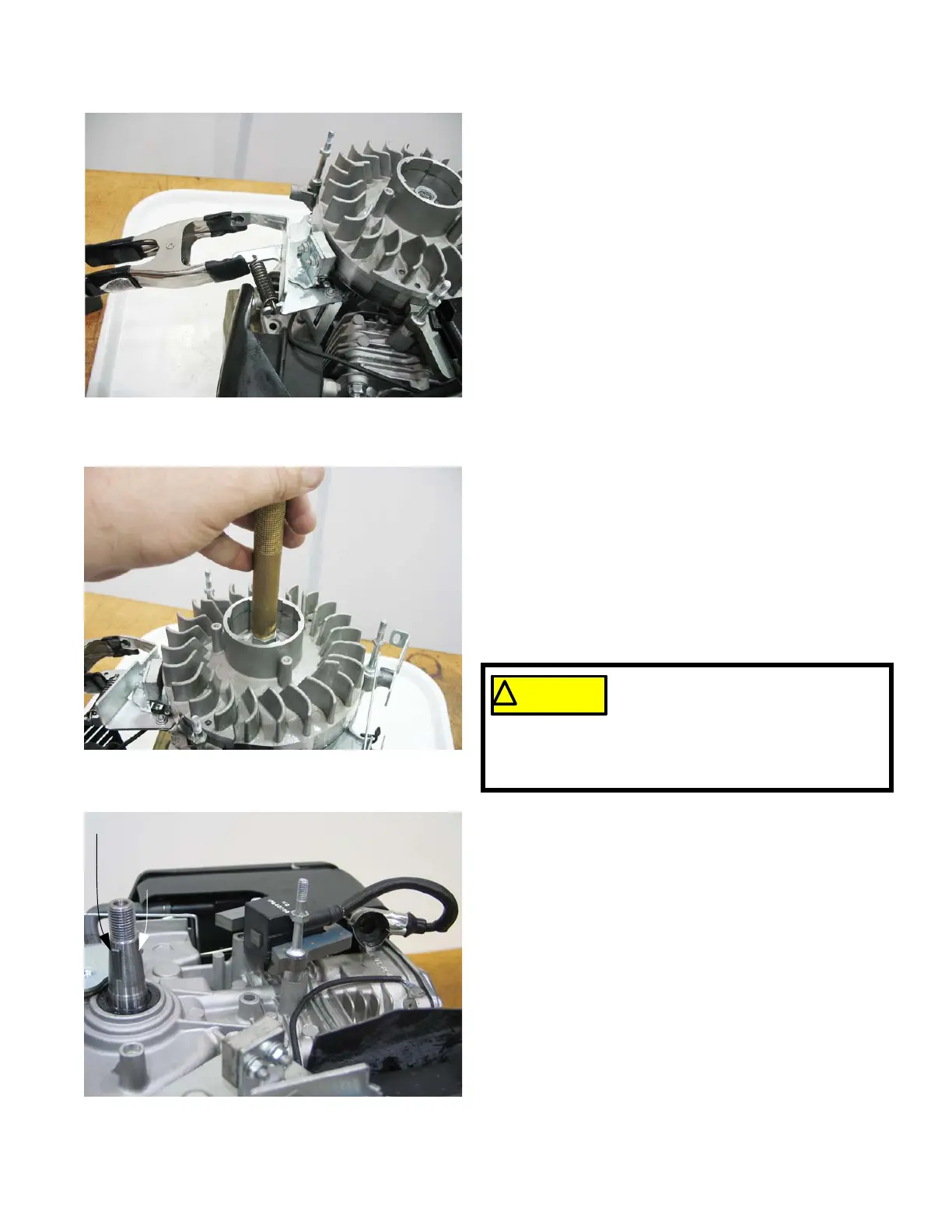

4. Remove the flywheel by applying a sharp blow to the

crankshaft using a brass drift punch and a hammer

while gently prying with a prybar. The flywheel will

“pop” loose then lift it off.

NOTE: Never strike the crankshaft directly with a hammer.

To prevent damage to the crankshaft use a brass

drift punch or a piece of wood between the ham-

mer and the crankshaft. See Figure 7.26.

5. Inspect the key, keyway, and tapered mating sur-

faces of the flywheel and crankshaft. See Figure

7.27.

NOTE: If the key is damaged it must be replaced. If there

is damage to the crankshaft key way, the engine

must be short blocked because crankshafts are

not available as a service part.

6. On installation, confirm that the key is properly

seated (the flat of the key parallel with the threaded

section of the crankshaft) in the key-way, and that

the tapers are fully seated. Key or keyway failure

may result from improper seating.

If the flywheel shows any signs of

physical damage such as cracks, bro-

ken vanes (if equipped), or a damaged

keyway, replace it. A damaged flywheel poses a

threat of a burst failure. Burst failures are extremely

hazardous to surrounding people and property.

Figure 7.27

Key flat parallel to the threads

Taper

Loading...

Loading...