14

INM5000-6 Jul 2010

6.4.2 Outputs

The output 1 relay reflects the status of the input and may be configured

to operate in reverse phase (PR) or with line-fault detection (LF). The

output 2 relay may be configured either to follow (slave mode) output 1

or as a line-integrity monitor (LFD) (see 6.4.3).

6.4.3 Line fault detection

(See section 3.1.4 for definition of a line fault)

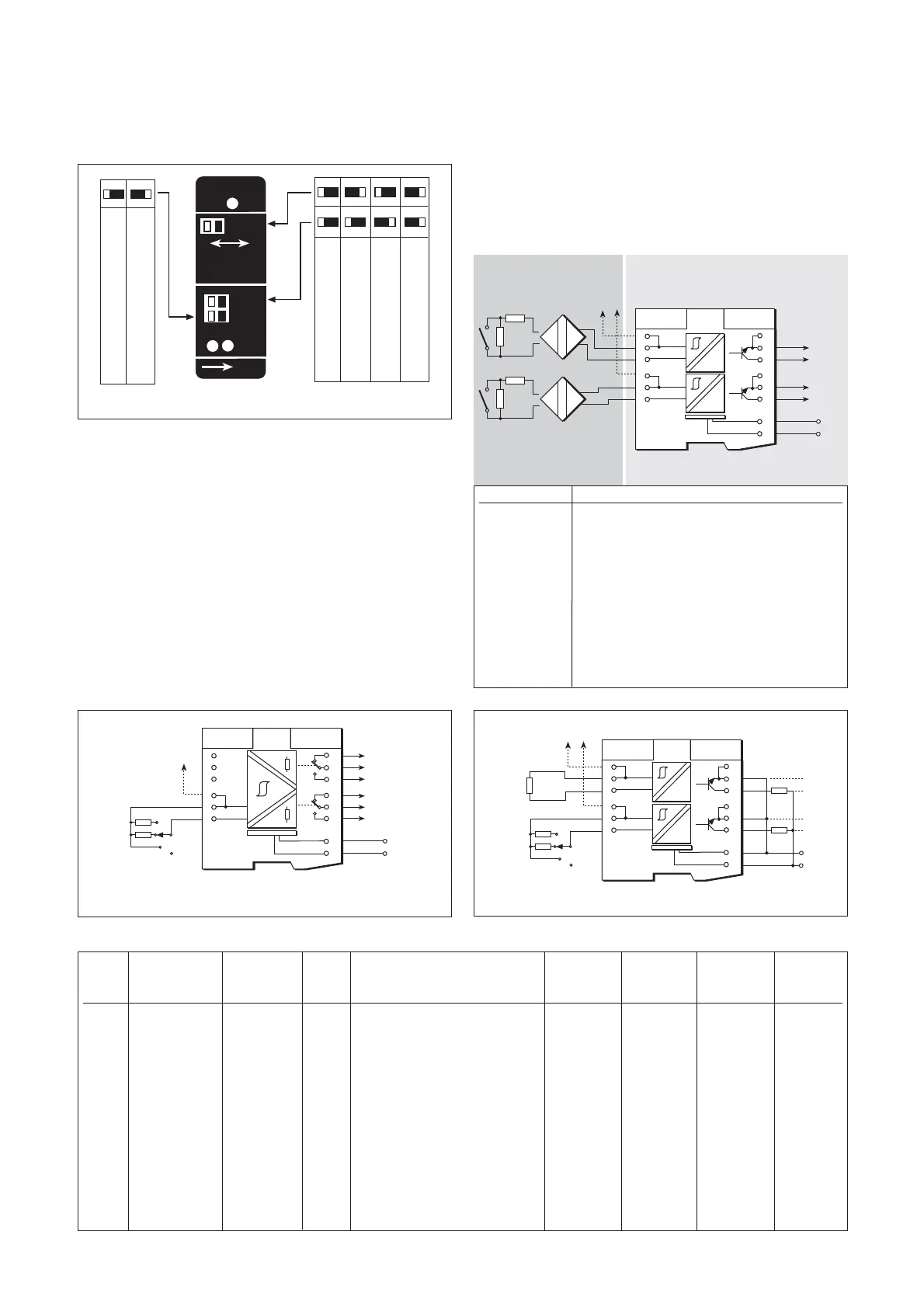

Line-fault detection and the operational mode of output 2 (ie slave to

output 1 or LFD) are selected by switches located on the top of the

module (see figure 6.8).

When LFD is selected for output 2 and there is a line fault in the sensor

circuit the output 2 relay is de-energised (providing an alarm output).

When LF is selected for output 1, the output 1 relay is de-energised if

there is a line fault in the sensor circuit. Note that resistors must be fitted

when using LFD with a contact input; 500Ω to 1kΩ in series, and 20kΩ

to 25kΩ in parallel with the switch.

6.4.4 Testing

Make the relevant safe- and hazardous-area connections shown in figure

6.9 for the tests listed in table 6.3. (Figure 6.8 shows the switch positions

for configuring output 2 slave/LFD, output 1 line fault (LF) and phase

reversal (PR)).

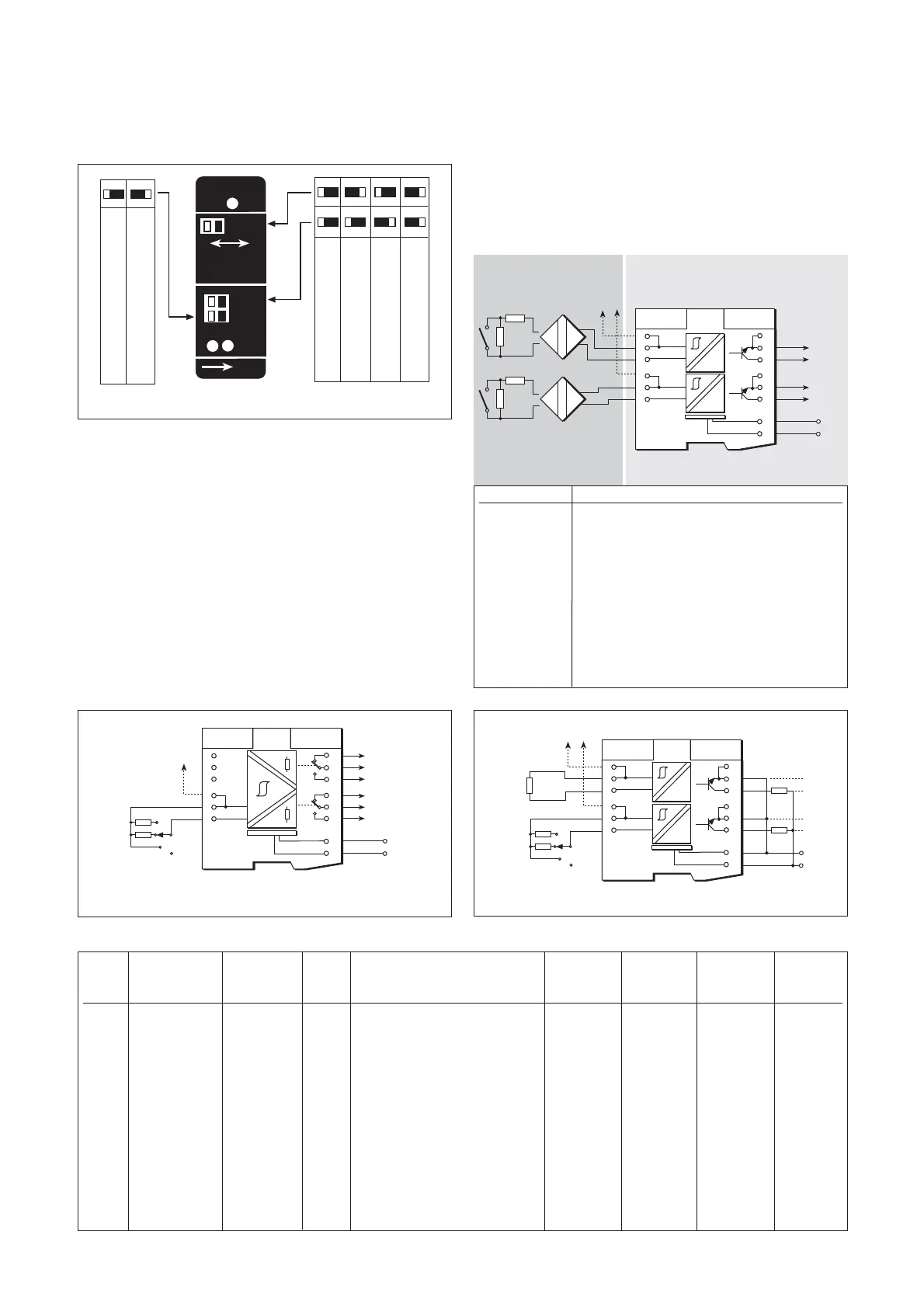

Table 6.3

6.5 MTL5015 solid-state two-channel

switch/proximity detector with line

fault detection and phase reversal

The MTL5015 enables each of two safe-area loads to be controlled,

through a solid-state output, by a switch or proximity detector in a

hazardous area. Line fault detection (LFD) and output phase reversal

(see 3.1.3) facilities are included.

6.5.1 Wiring connections

See figure 6.10 for wiring connections.

Phase Line fault Output 1 Output 2 Status Fault

reverse detection Slave Input test switch position relay relay LED LED

Test switch (PR) (LF) (LFD) (terminals 1 & 2) (11-12) (9-8) (yellow) (red)

1 Normal Off LFD (a) i.e. short-circuit Closed Open On On

2 Reverse Off LFD (a) short-circuit (I

sc

=7–9mA) Open Open Off On

3 Normal On Slave (a) short-circuit Open Open Off On

4 Normal Off Slave (a) short-circuit Closed Closed On Off

5 Normal Off Slave open-circuit (V

oc

=7V5–9V5) Open Open Off Off

6 Normal On Slave open-circuit Open Open Off On

7 Normal Off LFD (b) 22kΩ Open Closed Off Off

8 Normal Off LFD (c) 680Ω Closed Closed On Off

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...