Temposonics

®

E-Series

Brief Instructions

I 8 I

4.1 Sensor mounting

NOTICE

For detailed mounting instructions see operation manual.

Sensors with stroke lengths ≥ 1 meter (≥ 3.3 ft)

Support horizontally installed sensors with a stroke length

from 1 meter (3.3 ft) mechanically at the rod end. Without the

use of a support, rod and position magnet may be damaged.

A false measurement result is also possible.

Longer rods require evenly distributed mechanical support

over the entire length (e.g. part no. 561 481).

Use an U-magnet for measurement.

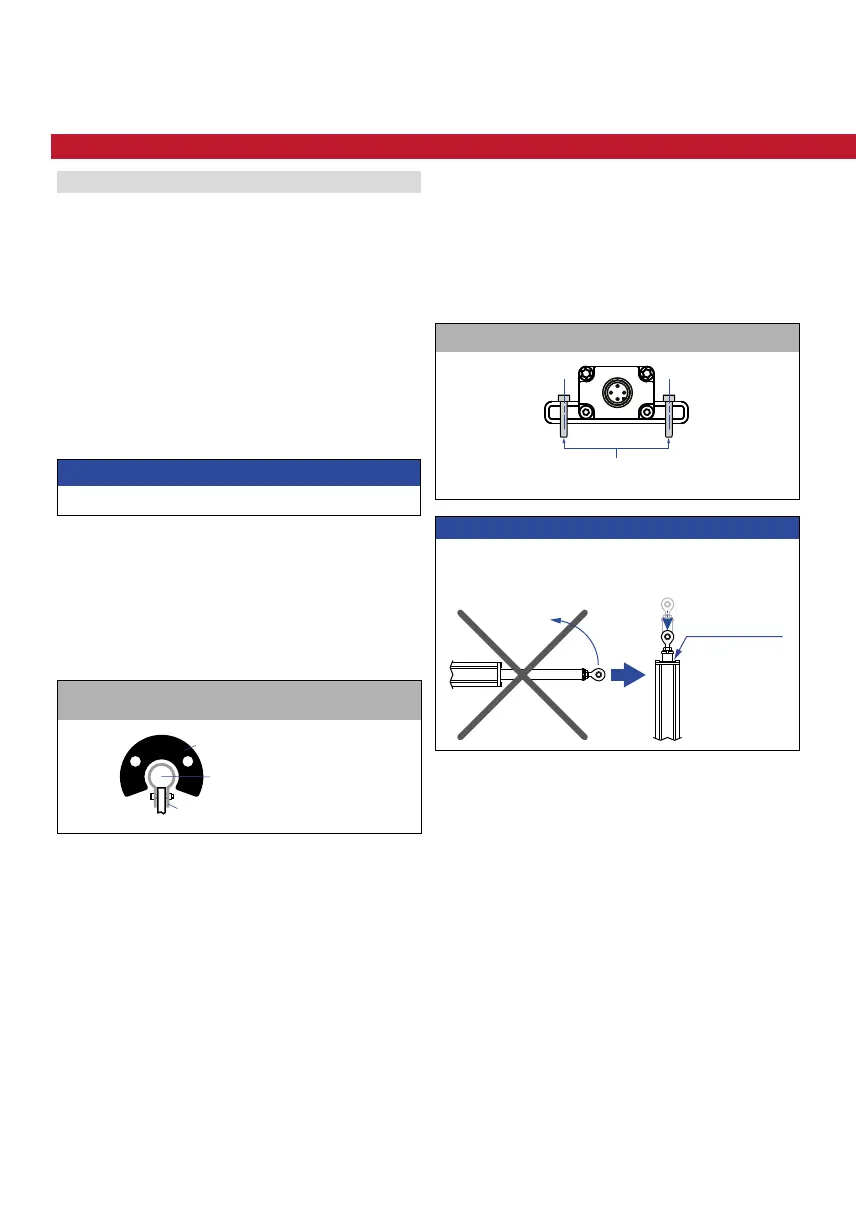

Mounting clamps

Screw: M5×20 (DIN 6912)

Sensor support

(for sensors with stroke lengths ≥ 1 meter (≥ 3.3 ft))

U-magnet

Sensor rod

Non-magnetic fixing clip

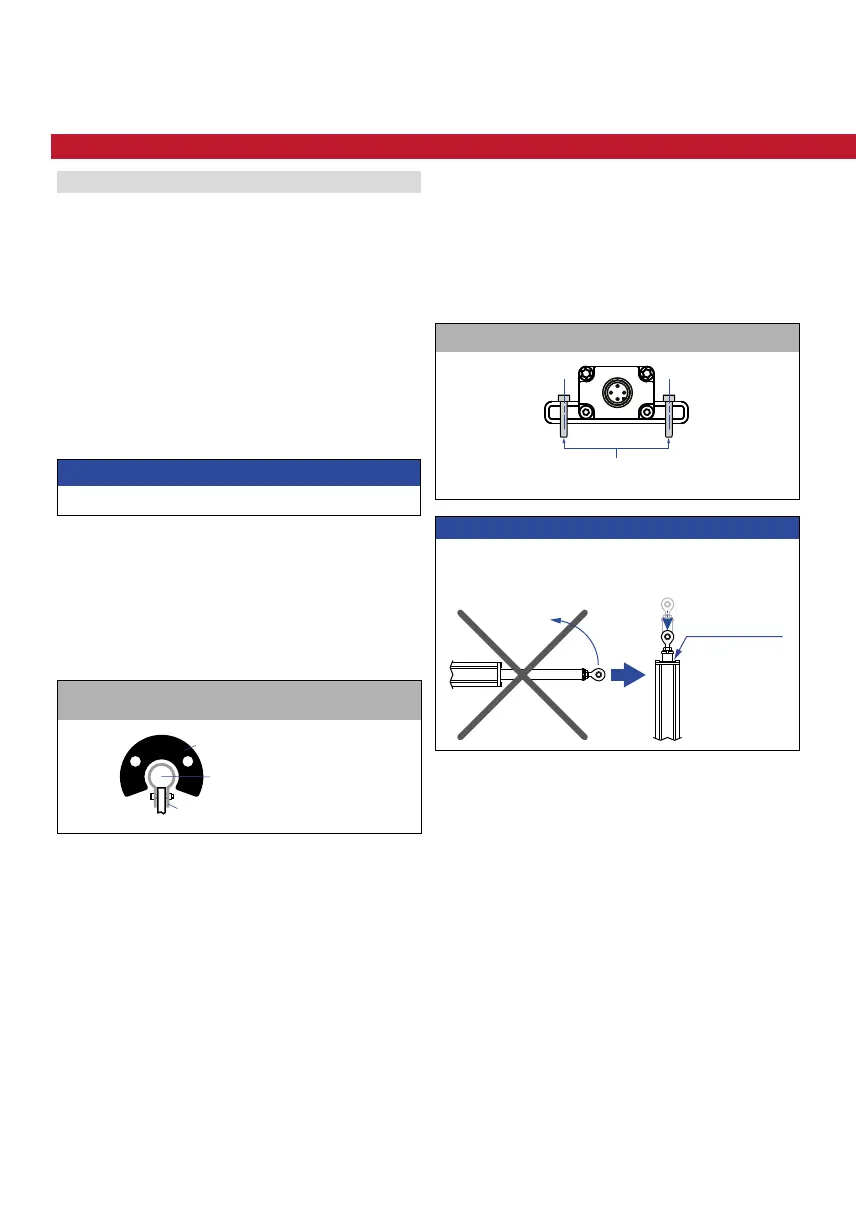

NOTICE

Do not raise up the ER sensor, if the lifting rod is

extended.

It causes

serious damage

Rod sensors – E-Series EH

• Fix the sensor rod via threaded flange.

• Note the fastening torque of 50 Nm.

• Seat the flange contact surface completely on the cylinder

mounting surface

• The cylinder manufacturer determines the pressure-

resistant gasket (copper gasket, O-ring, etc.).

• The position magnet should not grind on the sensor rod.

• The piston rod drilling

(Ø 10 mm rod: ≥ Ø 13 mm (≥ Ø 0.52 in.) borehole /

Ø 7 mm rod: ≥ Ø 10 mm (≥ Ø 0.4 in.) borehole)

depends on the pressure and piston speed.

• Adhere to the information relating to operating pressure.

• Protect the sensor rod against wear.

Profile sensors – E-Series EP / EL / ER / EP2

The sensor is fitted on a flat machine surface using mounting

clamps. A length-dependent number of these clamps are

delivered with the sensor and must be distributed over the

profile at regular distances.

For fastening, we recommend using M5×20 screws

(according to DIN 6912) that should be tightened with

a fastening torque of 5 Nm.

4. Installation & mounting

Loading...

Loading...