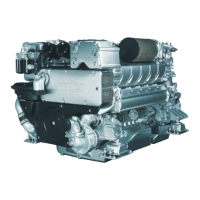

What to do if MTU Engine doesn't turn over when starting?

- SSteven WongAug 7, 2025

If your MTU Engine doesn't turn over when you try to start it, there are several potential causes. The battery might be flat or defective, in which case you should charge or replace it according to the manufacturer's documentation. Also, the cable connections on the battery might be defective, so check if they are properly secured according to the manufacturer's documentation. Other potential causes include defective engine wiring or a defective starter. Furthermore, the plug connections could be loose at the interface module EIM, so check those connections.