What to do if coolant leaks at intercooler of MTU 16 V 2000 G56 S?

- TTamara VasquezSep 13, 2025

If coolant leaks at the intercooler of your MTU Engine, especially with major coolant discharge, contact Service.

What to do if coolant leaks at intercooler of MTU 16 V 2000 G56 S?

If coolant leaks at the intercooler of your MTU Engine, especially with major coolant discharge, contact Service.

| Engine Type | Diesel |

|---|---|

| Number of Cylinders | 16 |

| Cylinder Arrangement | V |

| Aspiration | Turbocharged |

| Cooling system | Liquid Cooled |

| Fuel system | Common rail |

Details essential requirements for all products, including nameplate information and general safety considerations.

Outlines organizational measures and personnel qualifications for safe operation, maintenance, and repair.

Specifies safety precautions before, during, and after maintenance and repair activities.

Covers fire prevention, noise safety, environmental protection, and handling of fluids and lubricants.

Explains the standard designations for engine sides and cylinders according to DIN ISO 1204.

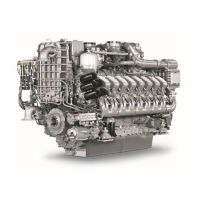

Provides a visual overview of the engine components with numbered labels for identification.

Presents detailed technical specifications for the 16 V 2000 G56 S engine model.

Presents detailed technical specifications for the 18 V 2000 G76 S engine model.

Lists the sequence of cylinder firing for both 16 V and 18 V engine configurations.

Provides key dimensions (length, width, height) for the engine models.

Details the procedure for recommissioning the engine after prolonged downtime.

Provides instructions and safety warnings for starting the engine.

Lists the checks to be performed during engine operation for monitoring and safety.

Describes the correct procedure for shutting down the engine, including cool-down.

Outlines the procedures and precautions for cleaning the engine and plant equipment.

Lists maintenance tasks, options, and references for application group 3B.

Lists maintenance tasks, options, and references for application group 3D.

Provides a guide to identifying and resolving common engine faults and issues.

Details the procedure for manually rotating the engine crankshaft using a barring device.

Provides instructions for performing a test run after maintenance or assembly.

Explains how to perform an endoscopic examination of cylinder liners.

Covers the procedure for checking and adjusting valve clearance.

Details the steps for removing and installing engine injectors.

Describes the process for replacing the high-pressure fuel lines and pipe necks.

Provides instructions for replacing the fuel filter element.

Explains how to drain water and contaminants from the fuel prefilter.

Details the procedure for replacing the air filter components.

Covers the steps for changing the engine oil, including filter replacement.

Describes how to check the engine coolant level.

Provides instructions for draining the engine coolant.

Explains how to inspect the condition of the drive belts.

Details the procedure for adjusting the tension of the drive belts.

Covers the process of removing and installing the engine governor.

Provides instructions for replacing the Lambda sensor.

Details the procedure for replacing the NOx sensor.

Provides an alphabetical list of abbreviations used in the manual.

Lists contact information for local support, 24h hotline, and spare parts service.

Lists special tools required for various tasks, including part numbers and usage.