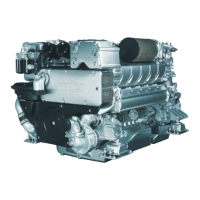

What to do if MTU Detroit Diesel 16 V 2000 P82 does not turn when starter is actuated?

- AAshley BoydJul 26, 2025

If the MTU Engine doesn't turn when the starter is activated, there could be several reasons. The battery might be low or defective, in which case you should charge or replace it, referring to the manufacturer's documentation for guidance. Also, check the cable connections to ensure they are properly secured, again consulting the manufacturer's documentation. If the issue persists, the engine wiring or starter itself may be defective, requiring a check of the cable connections or contacting service. Loose plug-in connections can also prevent the engine from turning, so inspect those as well. Finally, if the running gear is blocked and the engine cannot be barred manually, it's best to contact service.