Do you have a question about the MUTOH XpertJet 1682WR and is the answer not in the manual?

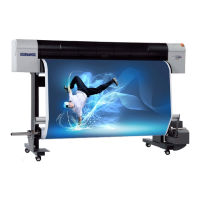

Identifies the XpertJet 1682WR as a 64-inch wide format dye sublimation printer.

Outlines usage limitations for product images, illustrations, and the document's content.

Introduces the XpertJet 1682WR as a successor model with enhanced output quality.

Defines target users including print service providers and businesses seeking high quality and volume.

Details various applications of the printer across different sectors.

Explains the meaning of the XpertJet 1682WR model number components.

Showcases the printer's capability for custom apparel, including personalized clothing and fast fashion.

Highlights applications in sportswear, swimwear, snowboards, skateboards, and helmets.

Covers applications in cushions, curtains, carpets, table cloths, and corporate furnishings.

Details uses in advertising, art replications, theatre backdrops, and information displays.

Explains applications for personalized gadgets like bags, umbrellas, mouse pads, and pillows.

Details print head type, nozzle configuration, and drop volume.

Covers print resolutions, head heights, media thickness, width, and measurements.

Explains variable drop technology for higher quality, photographic detail, and reduced cost.

Features LED lights for easy inspection of calibration prints and print quality during operation.

Details the OLED panel with improved image quality, lower power, and multi-language support.

Enables tracking media length using barcodes for efficient roll management.

Automatically adjusts jet fire timings based on media thickness for better image definition.

Introduces automated bidirectional alignment via a color sensor for calibration and reduced waste.

Provides automated paper feed adjustment using a built-in color sensor for benefits like reduced waste.

Compares output quality to VJ-1638WX and lists print speeds for various resolutions.

Highlights Intelligent Interweaving (i²) and 1440 dpi print quality with variable drop families.

Explains benefits like better printing quality, operator comfort, and reduced production loss.

Details the evolution from VSM to MSM, featuring a new GUI and multilingual support.

Describes mobile connectivity for remote printer control and Mutoh's Printer Club membership.

Lists desktop features such as printer status, heater info, remaining ink, and print details.

Highlights pressure roller handles, pinch roller system, roll off, and media feed flanges.

Explains how to insert and lock media flanges into the media roll core.

Describes the newly built roll-off system where media rolls rest on movable sliders.

Features new multi-level pinch rollers with adaptable pressure for various media types.

Details the four pressure levels (High, Middle, Low, Partial) for different media handling needs.

Describes the 30 kg torque winder system with motorized take-up and adjustable torque.

Details the 40 kg torque winder system with larger diameter capacity and power saving functions.

Explains the 100 kg system for heavy rolls, ensuring secure winding and clean output.

Highlights the PCB box at the rear for easy access to electronics and separation of wet parts.

Covers operator-performed maintenance like individual head cleaning and user-replaceable wipers.

Allows selecting active nozzle blocks to eliminate downtime when nozzles cannot be recovered.

Details the configuration including printer, 30 kg winder, flanges, and bulk ink system.

Details the configuration including printer, 40 kg winder, flanges, and bulk ink system.

Details the configuration including printer, 100 kg feed/take-up system, flanges, and bulk ink system.

Indicates that this section contains information exclusively for Mutoh Certified Distributors.

Provides a technical explanation of performance modes, speeds, and controlled variable drop settings.

Lists key factors affecting media feed stability: pinch rollers, vacuum fan, flanges, and tension control.

Provides step-by-step guidance for handling thin transfer paper, including pressure and vacuum settings.

Specifies the warranty period for the unit (2 years) and print heads (6 months or 6x10^9 droplets).

Details package size, weight, and recommended installation location requirements for safety and optimal operation.

Lists available accessories such as cutter blades, flushing pads, cleaning sticks, and media flanges.

Specifies recommended temperature, humidity, power requirements, and power consumption levels.

Provides packaging dimensions and weight for the printer and compatible winding systems.

Directs users to website, Startup Guide, Operation Manual, and Maintenance Manual for activation and maintenance.

Guides users to find retail pricing, technical information, and datasheets on the Mutoh website.

Lists the revision history, noting the first version was released in April 2021.