3/15 IOM-SDTU

Nailor Industries Inc. reserves the right to change any information concerning product or specification without notice or obligation.

Page 2 of 4

Labels

Single duct terminals units are shipped from the factory with the following information labels.

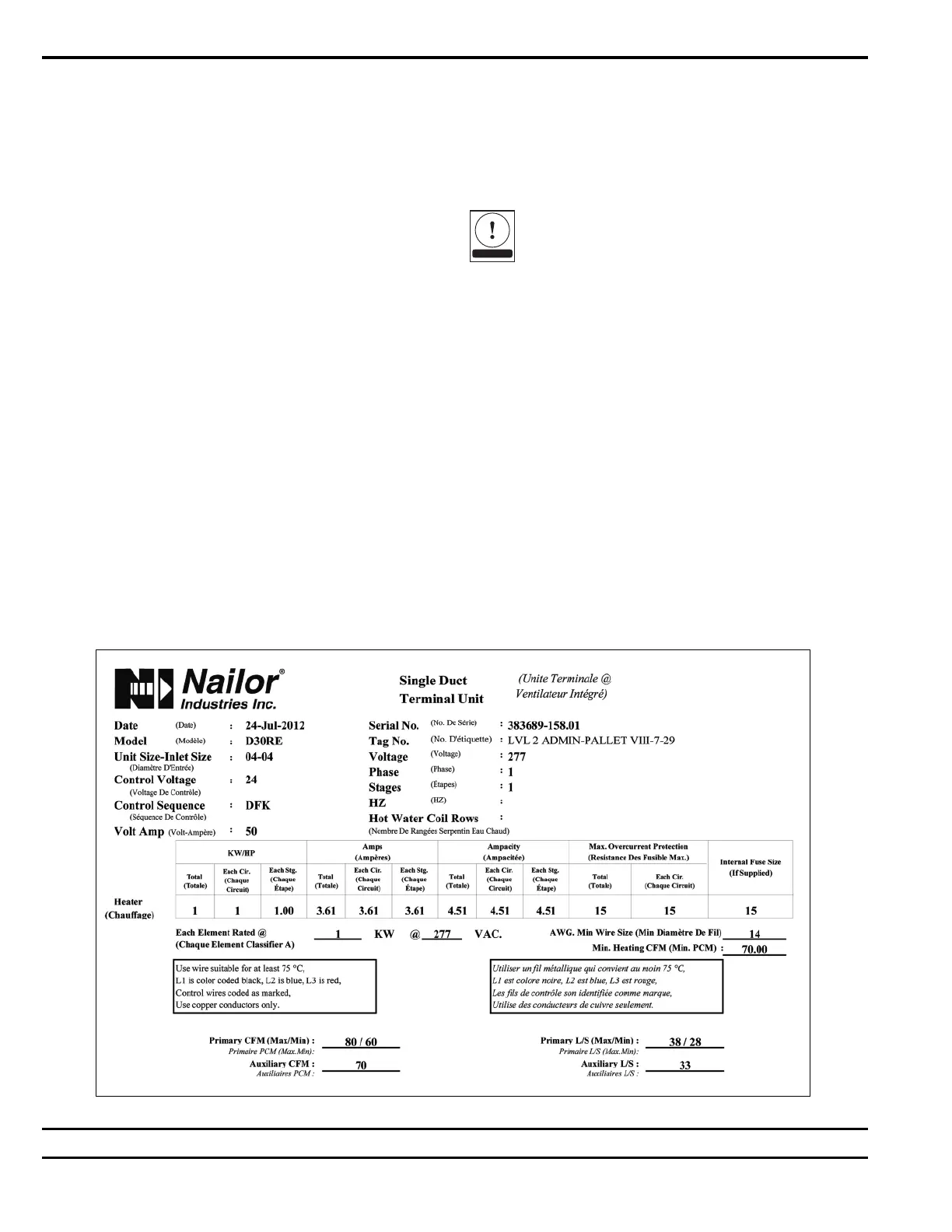

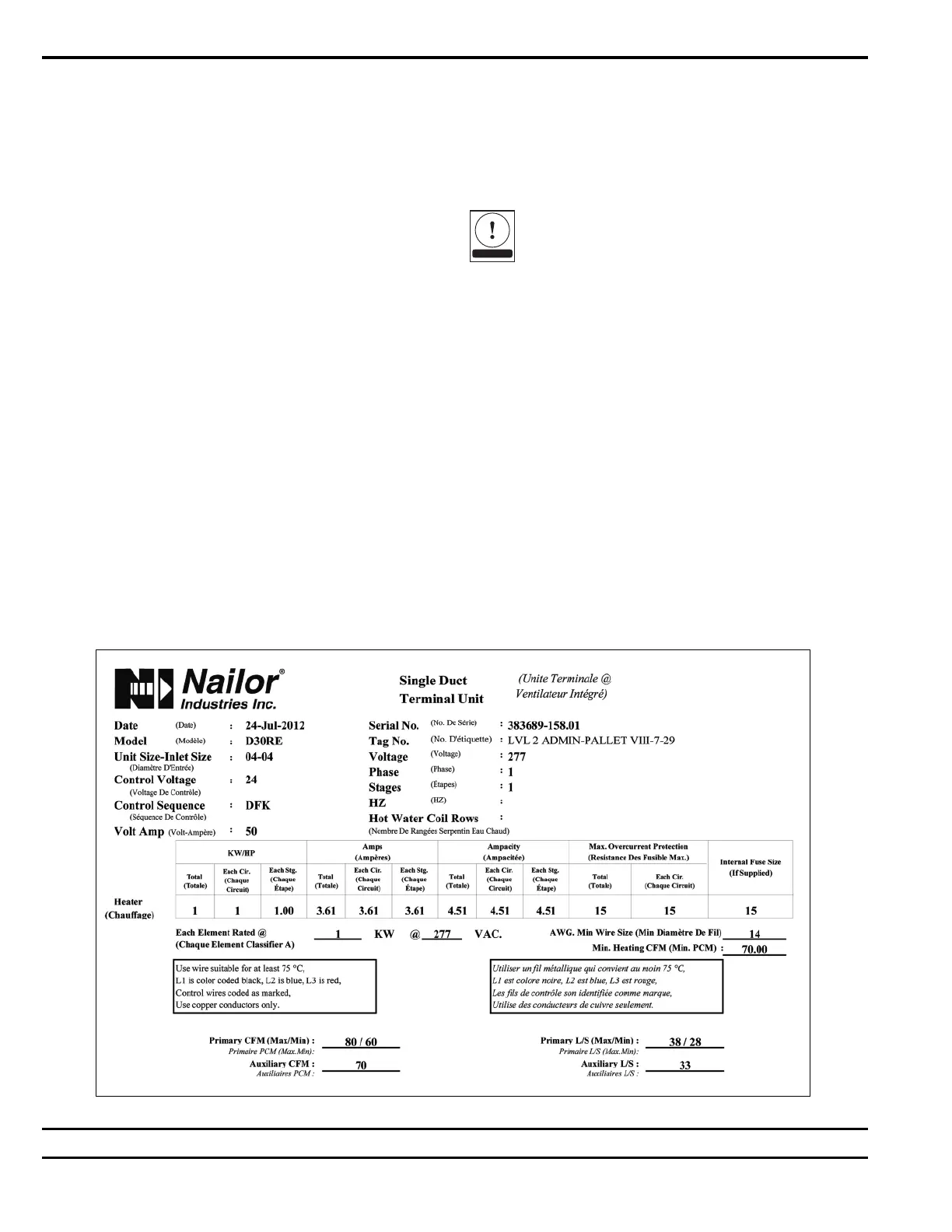

1) Sample Nameplate Label

– affixed to the air terminal casing beside the control mounting panel. Shows tagging information, serial-model number, size, cfm, voltage,

amps, MOP, etc.

Duct Connections

Slip each inlet duct over the inlet collar of the terminal. Fasten and

seal the connection as described in the job specification. The

diameter of the inlet duct for round inlets (unit size 4 through 10)

must be equal to the listed size of the terminal. The inlet collar of

the terminal is made 1/8" (3) smaller than listed size in order to fit

inside the duct (see figure 1). Unit size 12 through 16 utilize flat

oval inlet collars and unit size 24 x 16 has a rectangular inlet collar.

The flat oval inlets are undersized for flexible duct connection. For

hard inlet duct connections, refer to submittal drawing for

dimensional data. On exhaust units the duct should mate to the

terminal using slip and drive connections (see Fig. 4).

Important: Do not insert ductwork inside the inlet collar of the

assembly. For optimum performance, 2 to 3 equivalent diameters of

straight duct should be installed prior to the inlet of the unit. All

ducts should be installed in accordance with SMACNA guidelines.

The outlet end of the terminal is designed for use with slip and drive

duct connections. A rectangular duct the size of the terminal outlet

should be attached.

Field Wiring

All field wiring must comply with NEC and local codes. Electrical,

control, and piping diagrams can be found on labels affixed to the

exterior/interior of the control enclosure box. All Nailor electric

heaters are staged per specifications. The installing electrician

should rotate the incoming electric service by phase to help

balance the building electric load.

IMPORTANT: Electric re-heat units ordered with SCR or

SSR, route field wiring near bottom of control box. Do not

place directly behind SCR or SSR.

Fuse size designates the size of the internal fuse if it is supplied.

Maximum Overcurrent Protection (MOP) designates the largest

breaker or fuse in the electrical service panel that can be used to

protect the unit.

Control Start-up and Operation

Your local Nailor Representative can provide detailed information

about start-up and operating procedures for Nailor’s digital, analog,

and pneumatic controls. For specific information on controls

provided by other manufacturers, contact the specific

manufacturer’s local or national office. This applies whether the

controls were factory or field mounted.

Note: Digital controllers may use specific communication addresses

based on Building Management Systems Architecture and original

engineering drawings. Installing the terminal in a location other than

that noted on the label may result in excessive start-up labor.

Loading...

Loading...