3/03 IOM-DDTU

Installation and Operation Manual

Dual Duct Terminal Units

Nailor Industries Inc. reserves the right to change any information concerning product or specification without notice or obligation.

Page 1 of 4

Receiving Inspection

After unpacking the assembly check it for shipping damage. If any

shipping damage is found, report it immediately to the delivering

carrier. During unpacking and installation do not handle by the inlet

velocity sensor or the control package.

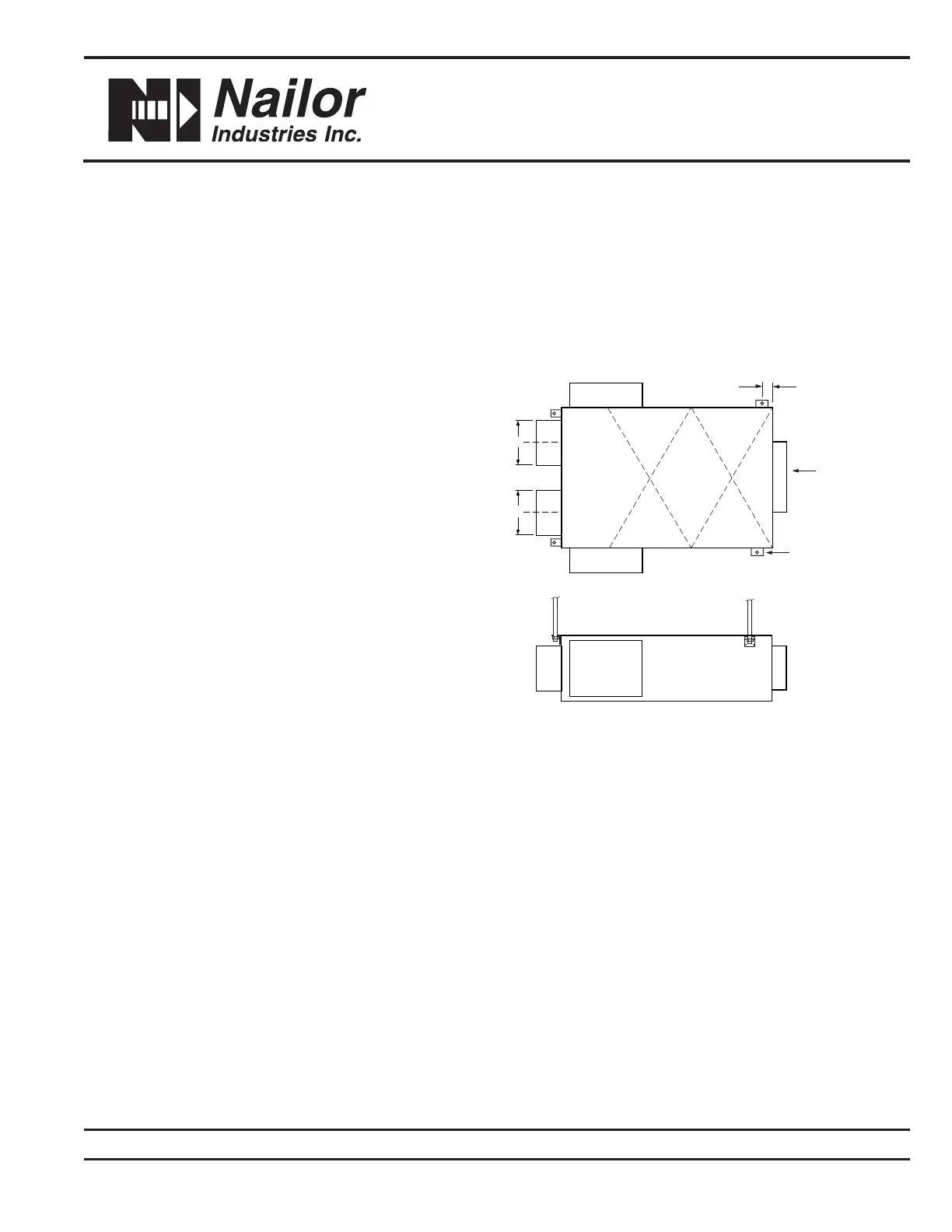

Supporting the Assembly

Dual duct units are designed to be independently supported. When

requested, unit is supplied with field mounted hanger brackets for

use with hanger rod up to 3/8" (9.5) dia. Hanger brackets should be

screwed into the top of the unit casing sides and/or the inlet and

outlet ends. Hanger straps may alternately be used and screwed

directly into the sides of the unit casing. Use the support method

prescribed for the rectangular duct in the job specifications.

Important: If unit is equipped with pneumatic controls, it should be

mounted right side up and level within ±10 degrees of horizontal

and parallel to the airflow. The terminal is marked with a label

stating "Top of Unit".The first letter in the model number indicates

control type (P is for pneumatic). If the unit is mounted upside

down, the controllers will have to be re-positioned, re-piped, and re-

calibrated. Analog control units (A-analog model number pre-fix)

may be installed in any orientation. Some Digital (DDC) controls (D-

digital model number pre-fix) are position sensitive dependent on

the airflow sensor transducer. Check with the controls manufacturer

for verification.

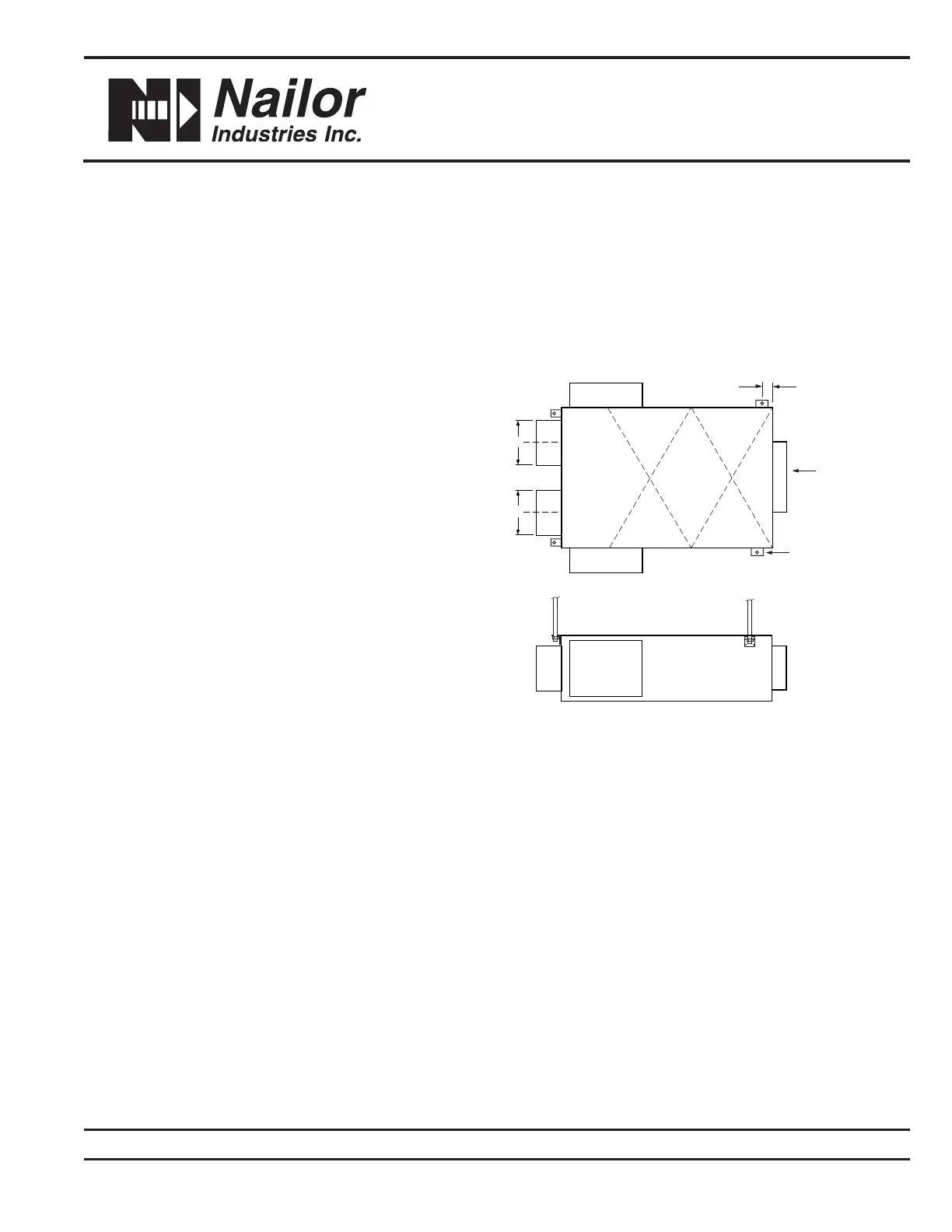

Duct Connections

Slip each inlet duct over the inlet collar of the terminal. Fasten and

seal the connection as described in the job specification. The

diameter of the inlet duct "D" (see Figure 1) for round inlets (Models

3230 and 3240 with mixing attenuators) must be equal to the listed

size of the terminal; i.e., a duct that actually measures 8" (203)

must be fitted to a size 8 terminal inlet. The inlet collar is made 1/8"

(3) smaller than nominal duct size in order to fit inside the duct.

Model 3210 (no mixing attenuator) utilizes flat oval inlet collars on

unit sizes 12 through 16. They are undersized for flexible duct

connection. For hard inlet duct connections, refer to submittal

drawing for dimensional data. The supply ductwork should be

insulated up to the face of the terminal unit.

Important: Do not insert duct work inside the inlet collar of the

assembly. For optimum performance, 2 to 3 equivalent diameter

of straight duct should be installed prior to the inlet of the unit. All

ducts should be installed in accordance with SMACNA guidelines.

The outlet end of the terminal for models 3230 and 3240 is supplied

with a rectangular collar. A rectangular duct the size of the terminal

outlet should be attached.

Model 3210 is supplied with slip and drive duct connections. A

rectangular duct, the size of the terminal outlet should be installed.

Loading...

Loading...