52 Installing the Water Heater

3.6.4 Selecting Vent Pipe Materials

Venting requirements differ in the US and Canada.

Consult the following chart or the most recent

edition of ANSI Z223.1/NFPA 54 or CAN/CGA B149.1,

as well as all applicable local codes and regulations

when selecting vent pipe materials. Do not use

cellular core PVC (ASTM F891), cellular core CPVC,

Radel® (polyphenylsulfone) for the exhaust vent.

WARNING

Carbon Monoxide Hazard

To prevent serious injury or death:

●

ONLY use approved venting materials.

●

NEVER mix different types of vent pipe

materials. The vent system may fail and harmful

flue products may leak into the living space.

The use of more than one type of pipe for the

vent piping will also void the warranty and

certification of the water heater.

Locale Recommended Vent Materials

USA

●

PVC/CPVC Schedule 40 or 80

(Solid Core)

●

UL1738 approved PVC or CPVC

●

Approved Polypropylene (PP)

●

Approved Stainless Steel (SS)

Canada*

●

Type BH Special Gas Vent Class

IIA (PVC)

●

Type BH Special Gas Vent Class

IIB (CPVC)

●

Type BH Special Gas Vent Class IIC

(Polypropylene/Stainless Steel)

* For installation in Canada, field-supplied plastic vent

piping must comply with CAN/CGA B149.1 (latest edition)

and be certified to the Standard For Type BH Gas Venting

Systems, ULC-S636. Components of this listed system

must not be interchanged with other vent systems or

unlisted pipes or fittings. All plastic components and

specified primers and glues of the certified vent system

must be from a single system manufacturer and must not

be intermixed with another system manufacturer’s parts.

The supplied vent connector and vent termination are

certified as part of the water heater.

The vent system shall be installed in accordance

with the water heater manufacturer and, if

applicable, the venting system manufacturer's

instructions.

This product is set to use PVC as the default vent

pipe material. If the return water temperature for the

application is higher than 140°F (60°C) to circulate

back to water heater, Exhaust Limit Control

(parameter settings) must be set to OFF. Otherwise,

the water heater will control maintain the exhaust

and DHW temperatures below 150°F (65°C) and

140°F (60°C) respectively.

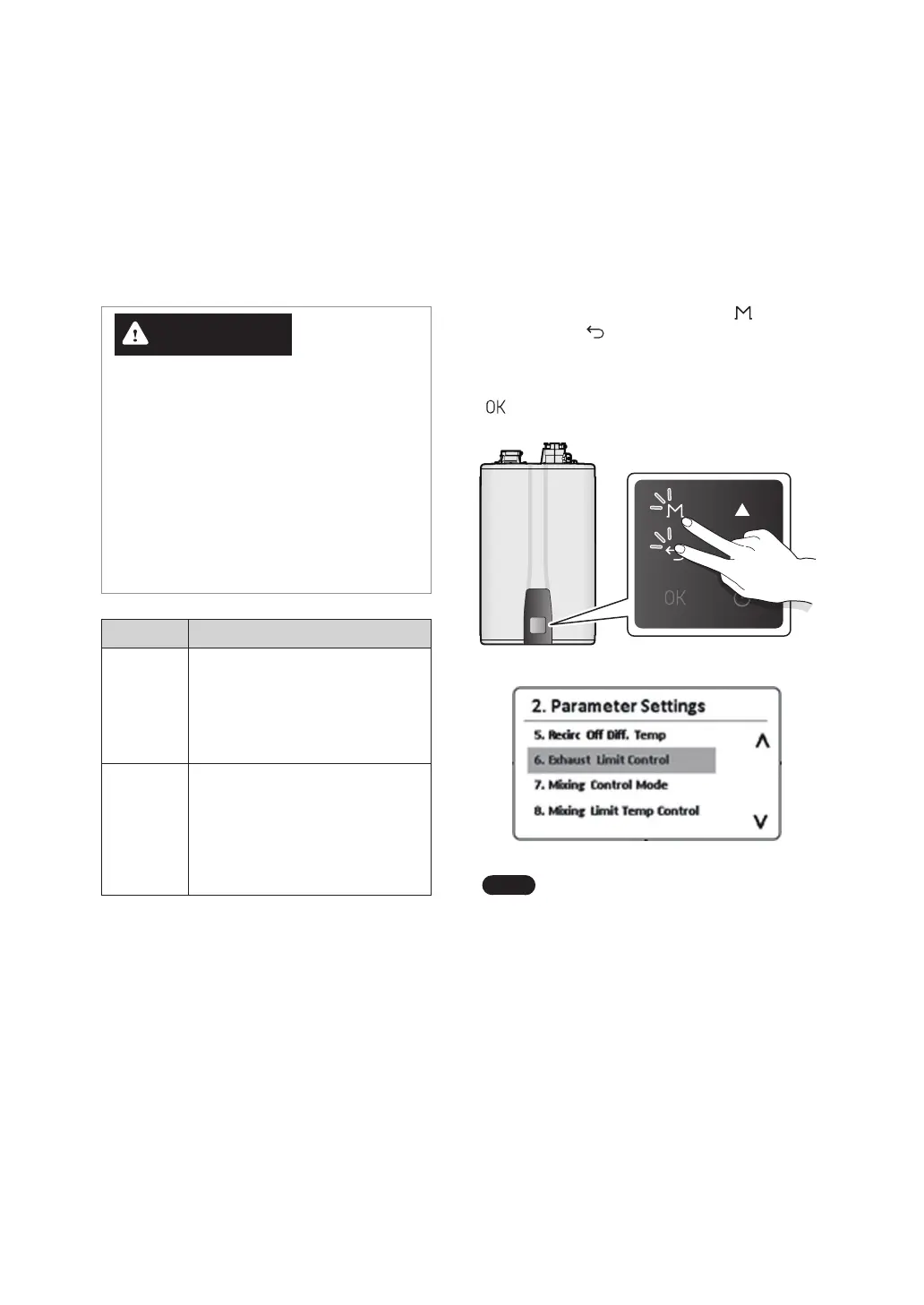

To change the Exhaust Limit Control parameter

setting, press and hold the Menu button (

) and

the Back button (

)

simultaneously for 3 seconds

to access the Service/Installer menu. Then select

1. Installer Menu > 2. Parameter Settings > 6.

Exhaust Limit Control by pressing the OK button

( ).

Note

●

When Exhaust Limit Control

(parameter settings) is set to Disable

(the factory default is Enable), CPVC,

PP, or SS vent must be used for the

exhaust pipe.

●

For more information about the

Parameter settings, refer to “6.8

Maintenance” on page 87.

Loading...

Loading...