IMO-218 EN - Issue 8/202016

9. MALFUNCTIONS

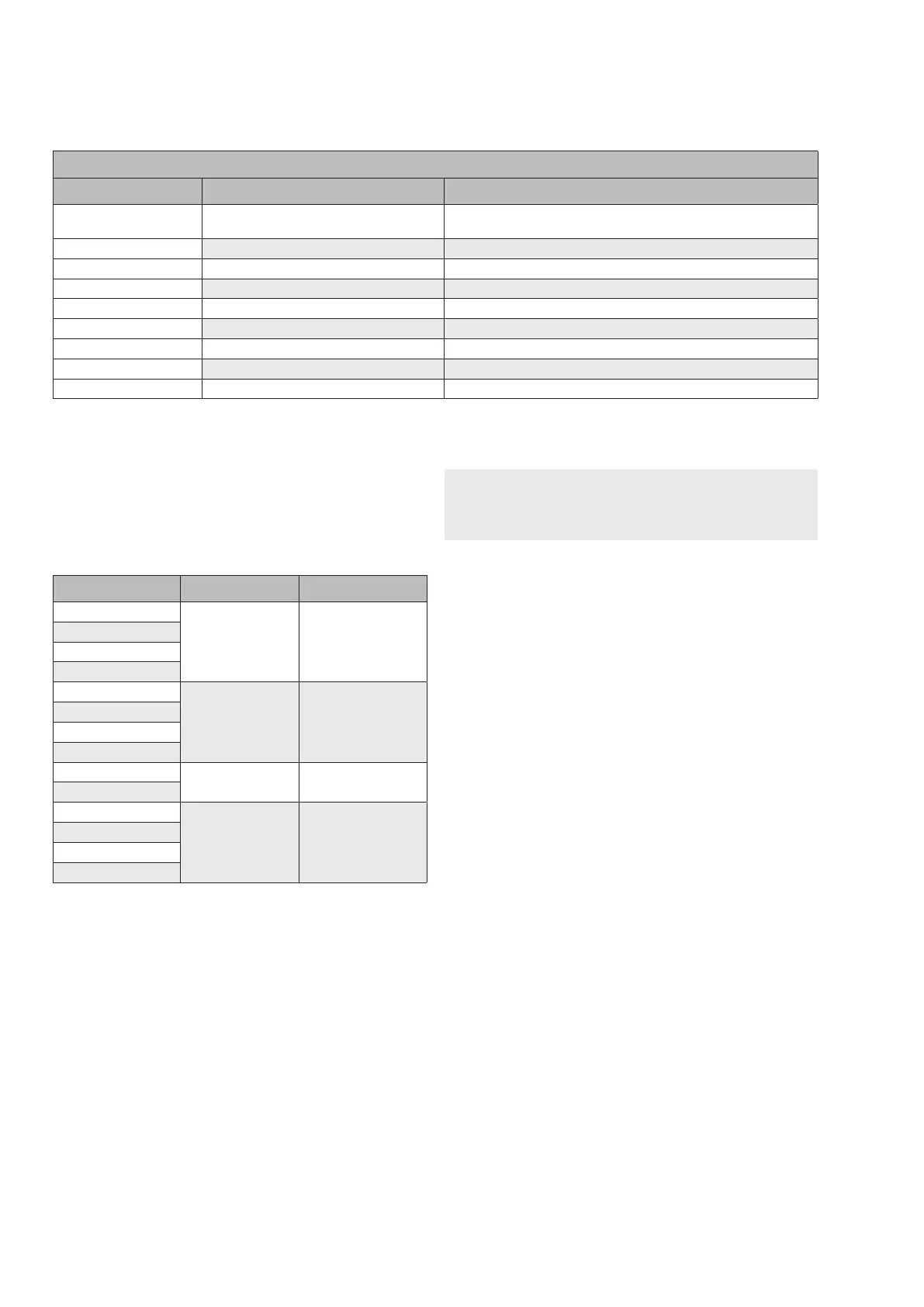

Table 5. lists malfunctions that might occur after prolonged use

Symptom Possible cause Action

Irregular or slow operation Low supply pressure Make sure that supply pressure complies with minimum torque required by

valve. Check that supply air pipes are large enough.

Positioner fault Check positioner operation.

Valve fault Check that valve functions properly without actuator.

Incorrect actuator rating Contact manufacturer to check rating.

Leak in piston or piston rod seal Replace seals.

Cylinder damaged by impurities Note installation position recommendation. Replace cylinder if damaged.

Worn-out actuator bearings Check bearings. Replace bearings when neccessary.

Moving parts corroded in harsh, humid conditions Replace the corroded parts.

Backlash in joint between actuator and valve Replace parts as necessary.

10. TOOLS

For maintenance of the RNP series actuator, you will need a few

common tools.

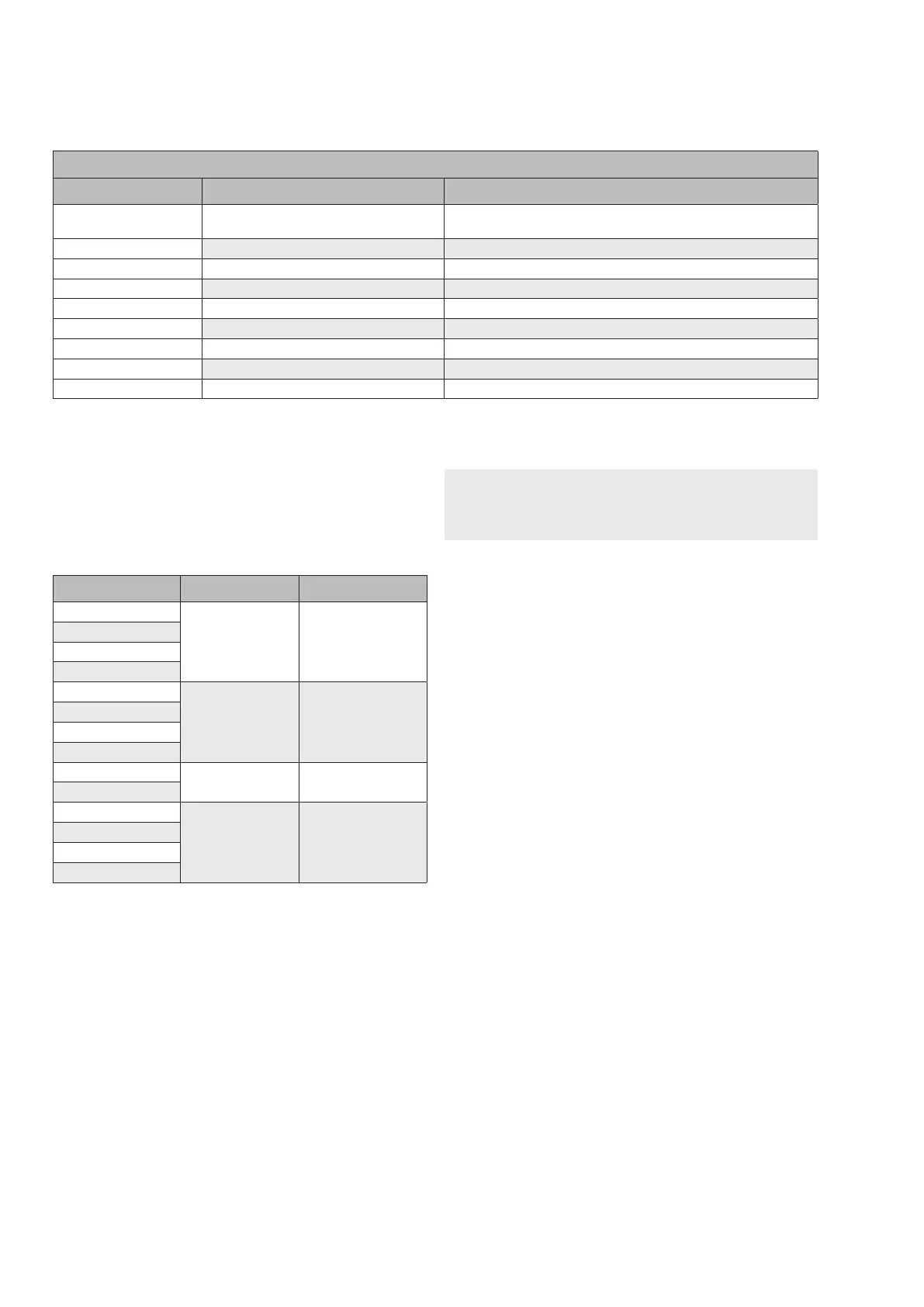

10.1 TIGHTENING TORQUE

TABLE

Actuator model Bolt size (#9) Tightening torque (Nm)

RNP 40

M6 8

RNP 50

RNP 63

RNP 80

RNP 90

M8 20

RNP 100

RNP 110

RNP 125

RNP 150

M10 40

RNP 175

RNP 200

M12 70

RNP 250

RNP 300

RNP 350

11. ORDERING SPARE PARTS

NOTE:

USE ONLY ORIGINAL SPARE PARTS. THIS ENSURES

PROPER FUNCTIONING OF THE ACTUATOR.

When ordering spare parts, always include following information.

• Type code, sales order number, serial number

• Number of the parts list, part number, name of the part and

required quantity

This information can be found from the identication plate or

documents.

Loading...

Loading...