16 • SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION INSTALLATION AND MAINTENANCE GUIDE

MAINTENANCE

PERIODIC CHECKS

Perform yearly or periodical checks at the beginning of the season, according to the following:

1. Replace the (4) 1.5V batteries at the beginning of every season or every six months;

refer to ‘Battery Removal & Replacement’.

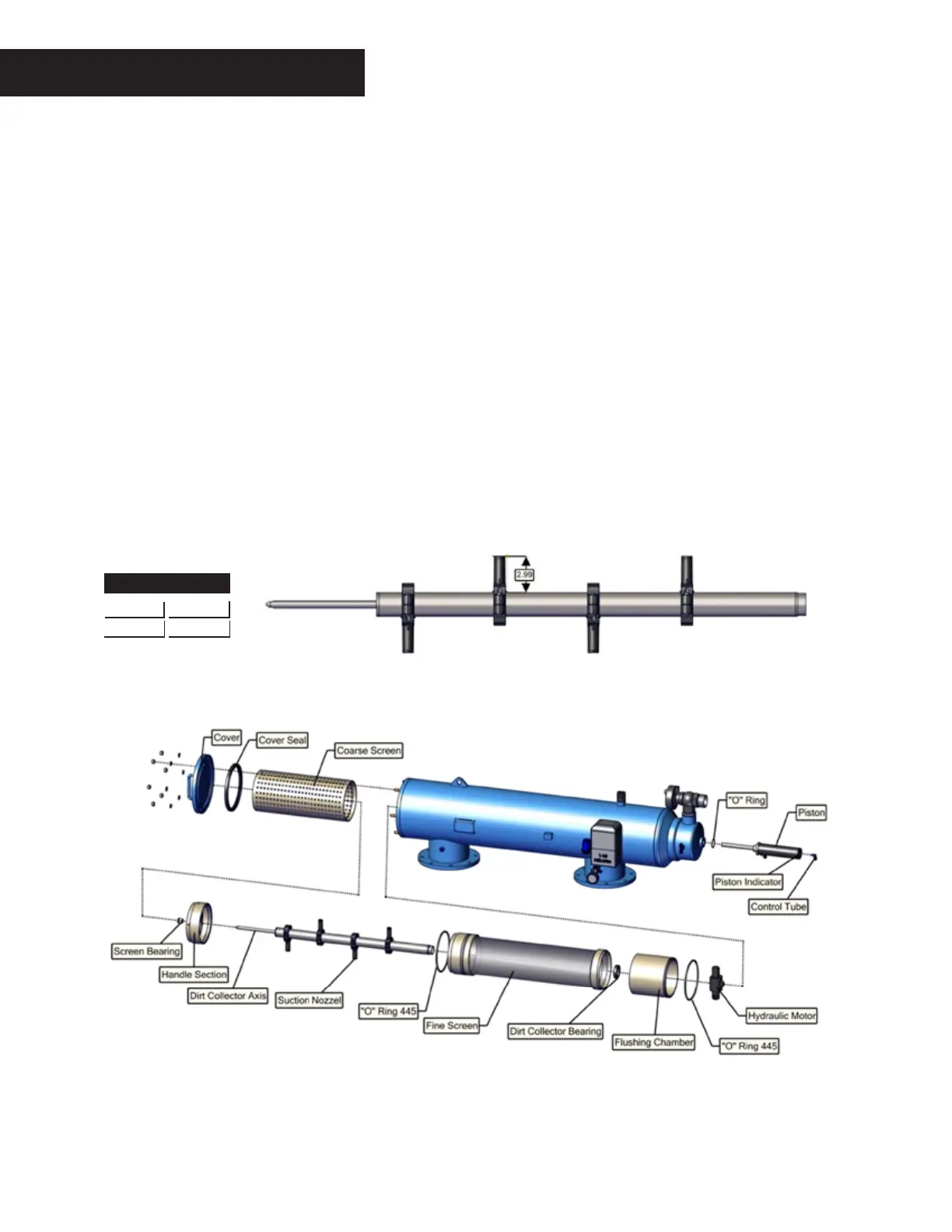

2. Check the condition of the coarse screen. If damaged, replace according to ‘Coarse Screen Removal & Replacement’.

3. Check the condition of the fine screen assembly. If damaged, replace according to ‘Fine Screen Assembly Removal &

Replacement’.

4. Check the condition of the dirt collector bearing and screen bearing. If any of the bearings have become misshaped, (oval),

replace with a new one.

5. Check the mechanical condition of the hydraulic piston assembly. Verify piston’s free movement. If damaged or deteriorated,

replace according to ‘Hydraulic Piston Assembly Removal & Replacement’.

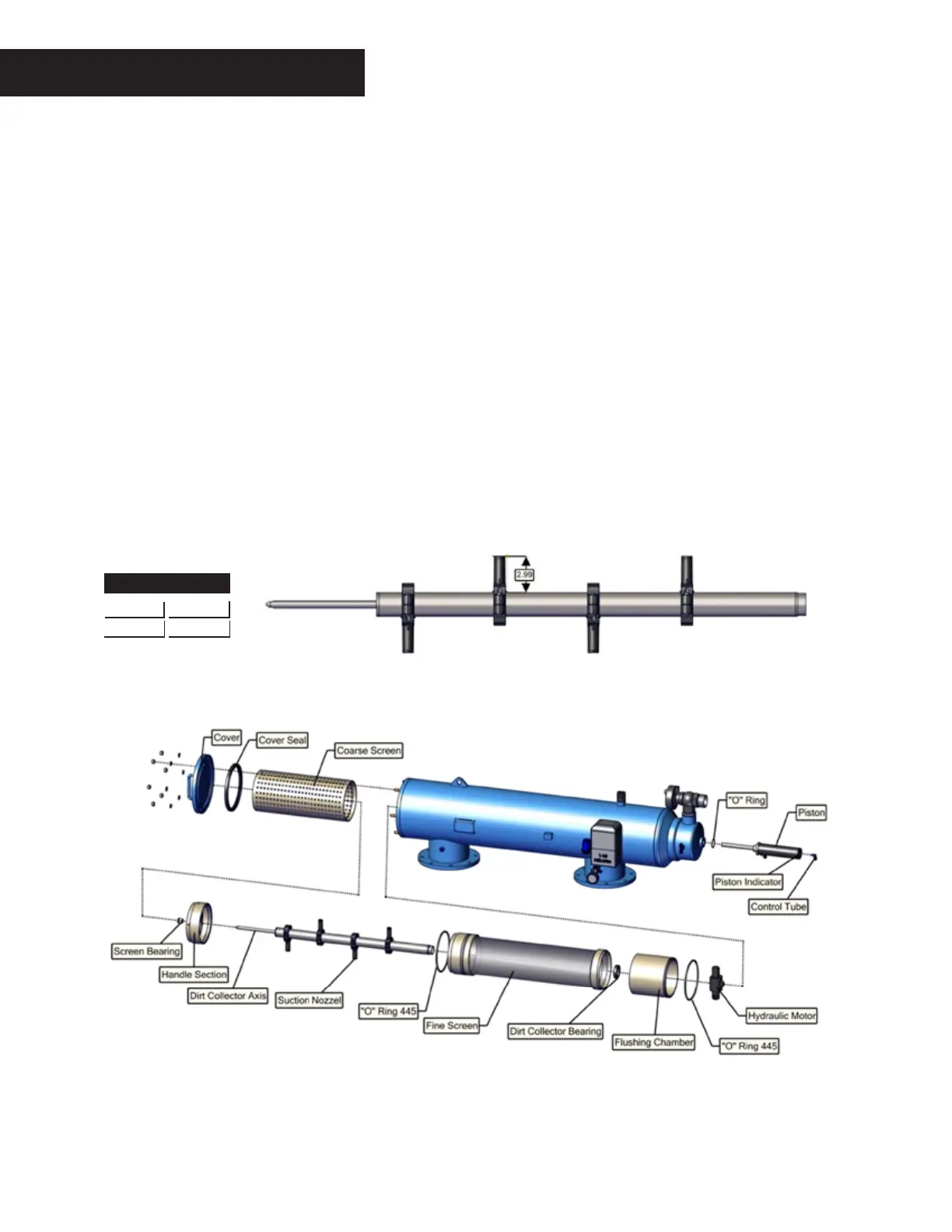

6. Check the dirt collector suction nozzles height (see table). If damaged, replace according to ‘Dirt Collector Removal &

Replacement’.

7. Check the condition of the controller while operating with running water.

8. Check the filter housing for paint damage or corrosion. If required, clean the area with sandpaper and apply a thin layer

of basic + epoxy paint.

9. Check for leaks.

FIGURE 11

NOZZLE HEIGHT

TYPE

2.99”

HEIGHT

All Filters

FIGURE 12

Loading...

Loading...