USER MANUAL

Initial Height Sensing

Because the cutting height is such a critical system parameter and the material surface is

inherently uneven, a Z axis mechanism needs a method to sense the material surface. There are

two methods this can be achieved. A “float” switch and an electrical or “ohmic” sensing circuit

that is closed when the torch shield contacts the material.

Float Switches

The torch is mounted on a sliding stage that can move up when the torch tip contacts the

material surface and trigger a switch or sensor. Also, Neuron controller use the switch hysteresis

obtained in the setup procedure.

Regardless what probing method is implemented, it is strongly recommended that float switch

is implemented so that there is a fallback or secondary signal to avoid damage to the torch from

a crash.

Ohmic Sensing

Ohmic sensing relies on contact between the torch and the material acting as a switch to

activate an electrical signal that is sensed by the Neuron controller. Provided the material is

clean, this can be a much more accurate method of sensing the material as a float switch which

can cause deflection of the material surface. This ohmic sensing circuit is operating in an

extremely hostile environment so a Neuron Ohmic contact sensor is implement to ensure safety

of both the CNC electronics and the operator. In plasma cutting, the earth clamp attached to the

material is positive and the torch is negative. It is recommended that The ohmic circuit uses a

totally separate isolated power supply that activates an opto-isolated relay to enable the probing

signal to be transmitted to the Neuron controller.

Corner Lock / Velocity Anti-Dive

The CNC trajectory planner is responsible for translating velocity and acceleration commands into

motion that obeys the laws of physics. For example, motion will slow when negotiating a corner.

Whilst this is not a problem with milling machines or routers, this poses a particular problem for

plasma cutting as the arc voltage increases as motion slows. This will cause the THC to drive the

torch down. Modern CNC systems like Mach3, Mach4, UCCNC, LinuxCNC support the real-time

macros that allow to enable or disable automatic voltage control from program g-code. Neuron

controllers has a separated Hi-Speed “THCOFF” input for this.

Head Safety Lock /Kerf Detect

If the plasma torch passes over a void while cutting, arc voltage rapidly rises and the THC

responds by violent downward motion which can smash the torch into the material possibly

damaging it. This is a situation that is difficult to detect and handle. To a certain extent it can be

mitigated by good nesting techniques but can still occur on thicker material when a slug falls

away. This is the one problem that has yet to be solved within the Neuron controller.

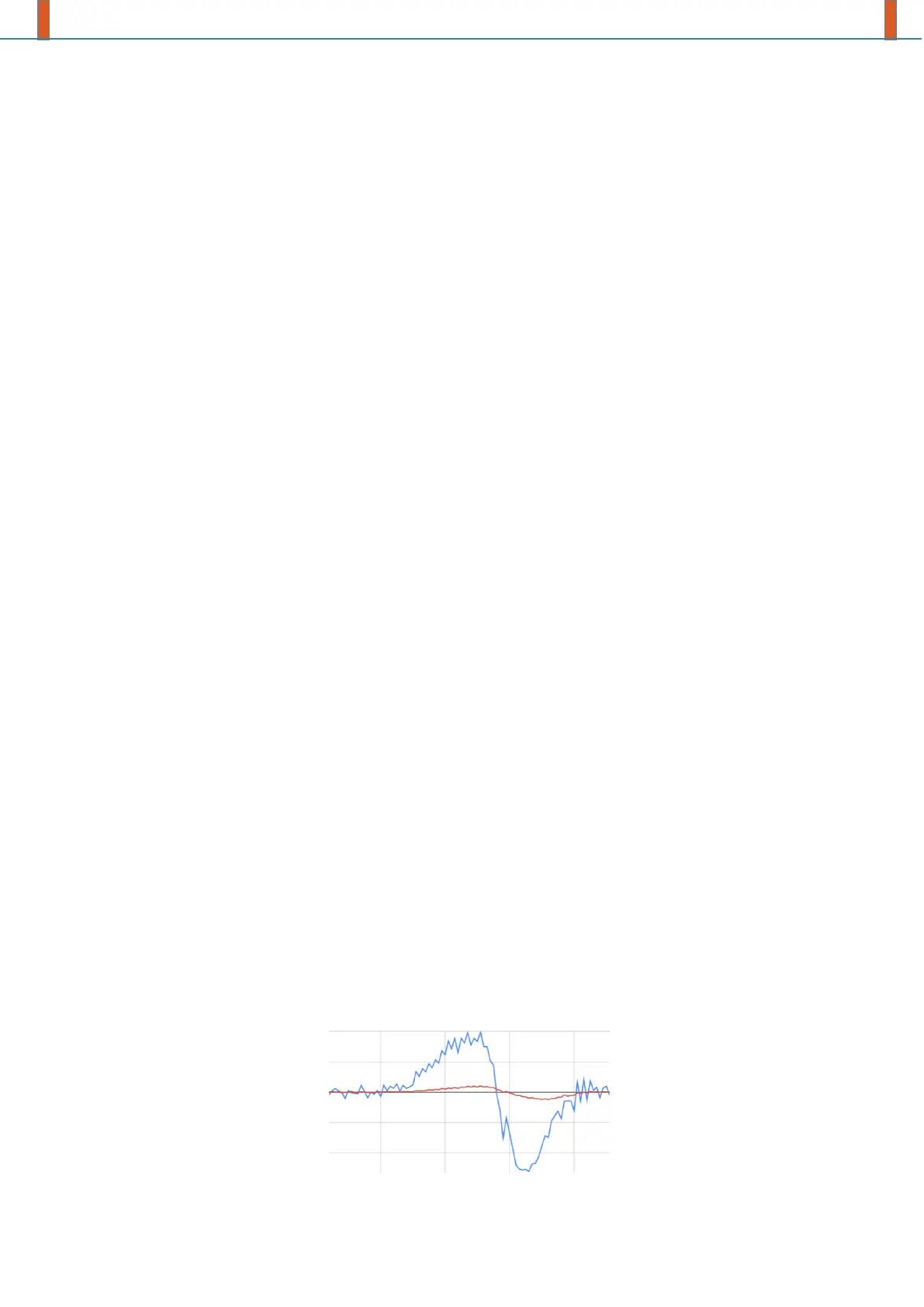

One suggested technique is to monitor the rate of change in torch volts over time (dv/dt)

because this parameter is orders of magnitude higher when crossing a void than what occurs due

to normal warpage of the material. The following graph shows a low-resolution plot of dv/dt (in

blue) while crossing a void. The red curve is a moving average of torch volts.

So, it should be possible to compare the moving average with the dv/dt and halt THC operation

once the dv/dt exceeds the normal range expected due to warpage.

Loading...

Loading...