QUICK REFERENCE CARD – NEW HOLLAND CX COMBINES

Form 147074 Rev. E (E27025) Page 2 of 4

873 Adapter Initial Settings

(continued)

Set the center link between the header and

adapter to 19-1/4” (490 mm) length (pin to

pin).

Set the float to specs given on pages 3 & 4.

Set the draper speed flow control so number

“4” is at the 12 o’clock position.

Header Initial Settings

See page 4 for 963 Header

For 973/974/84C Model Headers: Set the

center delivery opening to 55.5” (1410 mm).

Position the decks so there is equal

overlap of adapter feed draper each

side.

Align the vertical edge of the rear deflectors

on the feed pan just inside the edge of the

feeder house opening to ensure smooth

crop flow.

Re-check skid plate clearance (set during

873 initial settings) with adapter inserted in

header. (see appropriate dimensions below)

Refer to 873 Operator’s Manual for further

details.

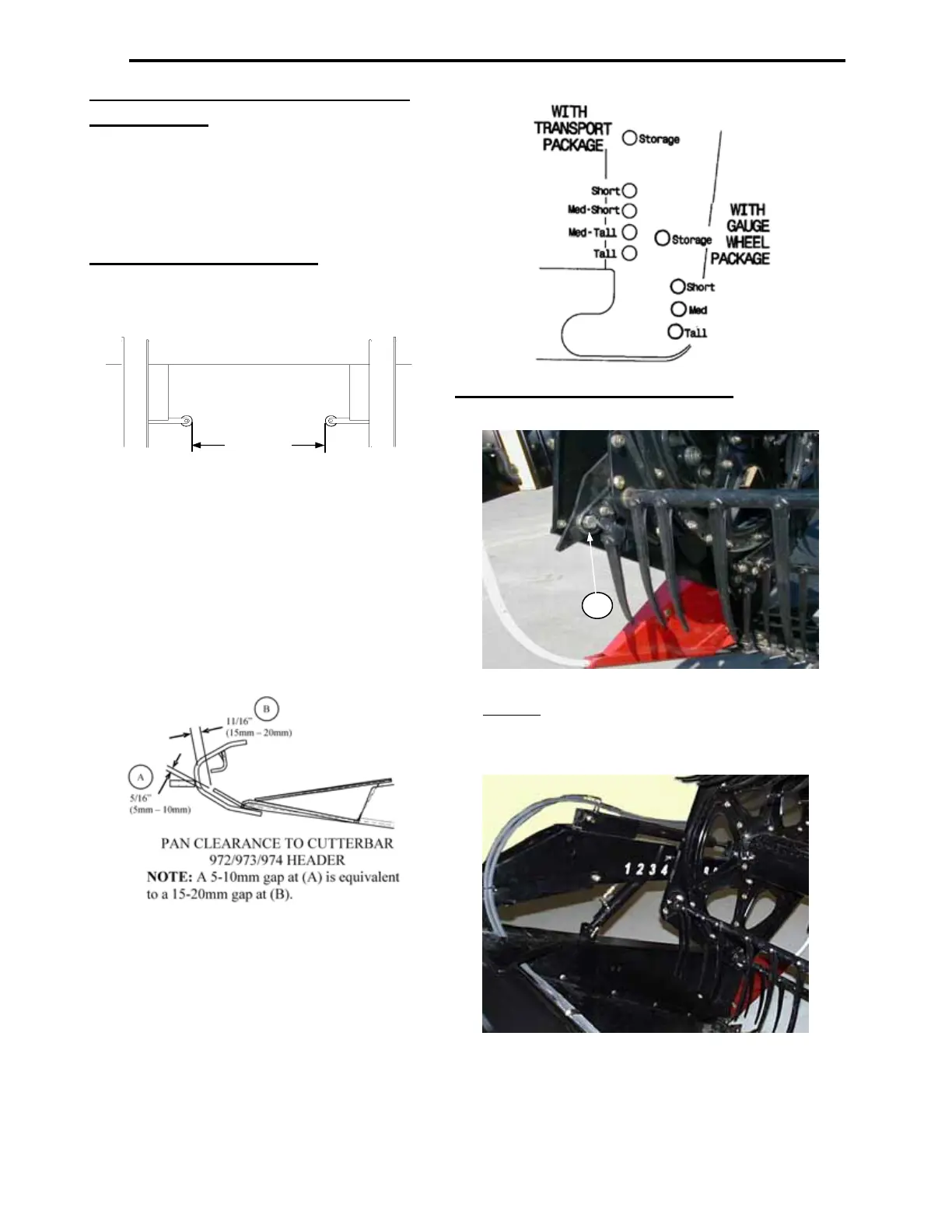

Gauge wheels are intended to help float the

header when cutting off the ground. For

such applications set gauge wheels in the

Short – Tall setting depending on cut height.

Note: When cutting on the ground place

gauge wheels in the storage position.

Pickup Reel Initial Settings

See page 4 for 963 Header

Install bolt (C) through the cam arm with head

inboard

and torque to 120 ft. lbs. (162 N·m.)

Adjust the finger pitch to position 5.

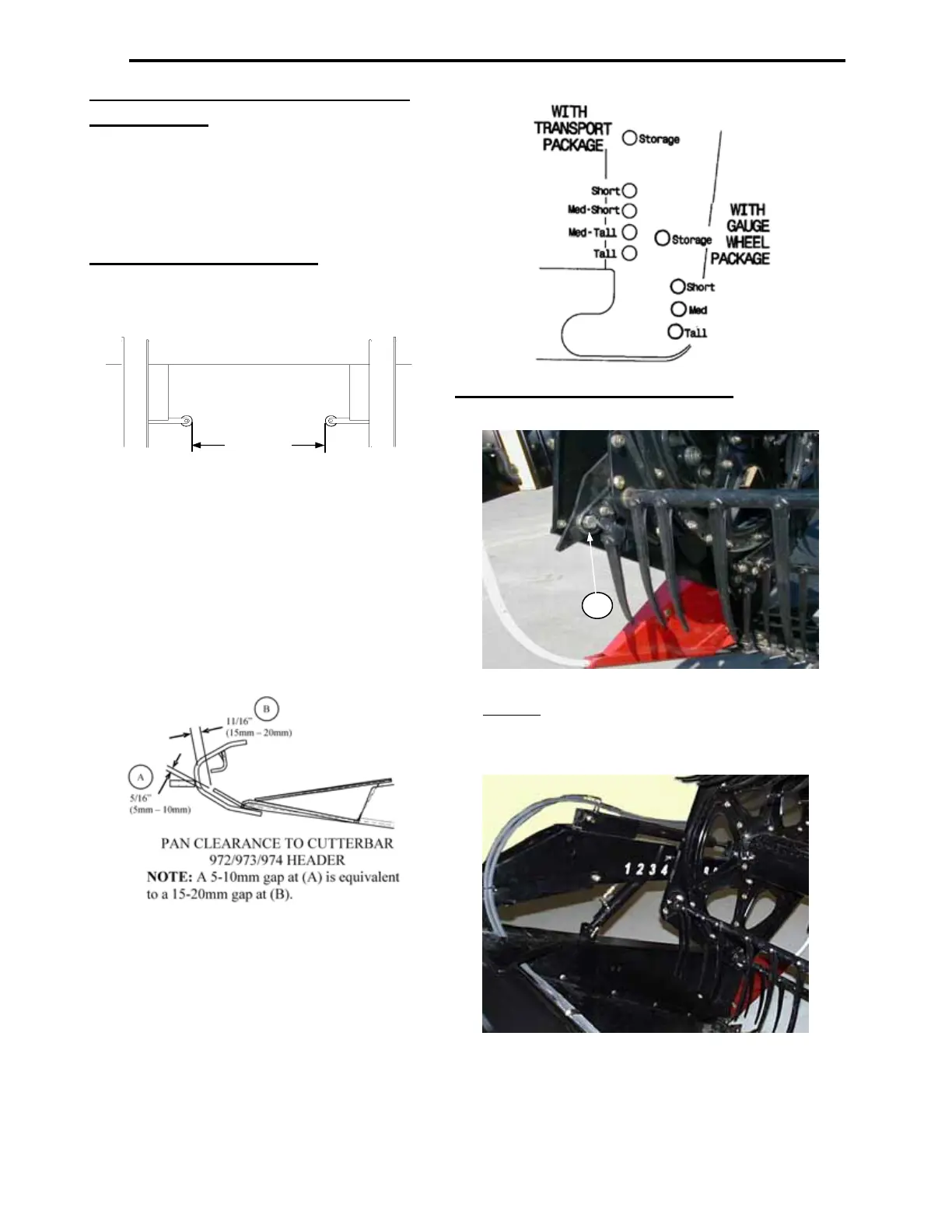

Set the fore/aft position to between 4 and 5 on

the gauge decal at left reel support arms.

Reel finger to sickle guard minimum clearance with

reel fully lowered is 5/8” (15mm), measured at

both ends of the cutterbar for 973 headers. For

974/84C headers, flex to full frown when

checking clearance at hinge points.

Recommended reel speed is 10% above ground

speed.

C

55.5”

1410 mm

973/974/84C

Loading...

Loading...