NI 9229/9239 Calibration Procedure | © National Instruments | 3

Test Equipment

Table 1 lists the equipment recommended for the performance verification and adjustment

procedures. If the recommended equipment is not available, select a substitute using the

requirements listed in Table 1.

Test Conditions

The following setup and environmental conditions are required to ensure the NI 9229/9239

meets published specifications.

• Keep connections to the device as short as possible. Long cables and wires act as antennas,

picking up extra noise that can affect measurements.

• Verify that all connections to the NI 9229/9239 are secure.

• (NI 9229/9239 with screw-terminal) Use shielded copper wire for all cable connections

to the device.

• Use twisted-pairs wire to eliminate noise and thermal offsets.

• Maintain an ambient temperature of 23 °C ± 5 °C.

• Keep relative humidity below 80%.

• Allow a warm-up time of at least 10 minutes to ensure that the NI 9229/9239 measurement

circuitry is at a stable operating temperature.

Initial Setup

Complete the following steps to set up the NI 9229/9239.

1. Install the NI-DAQmx driver software.

2. Make sure the NI cDAQ-9178 power source is not connected.

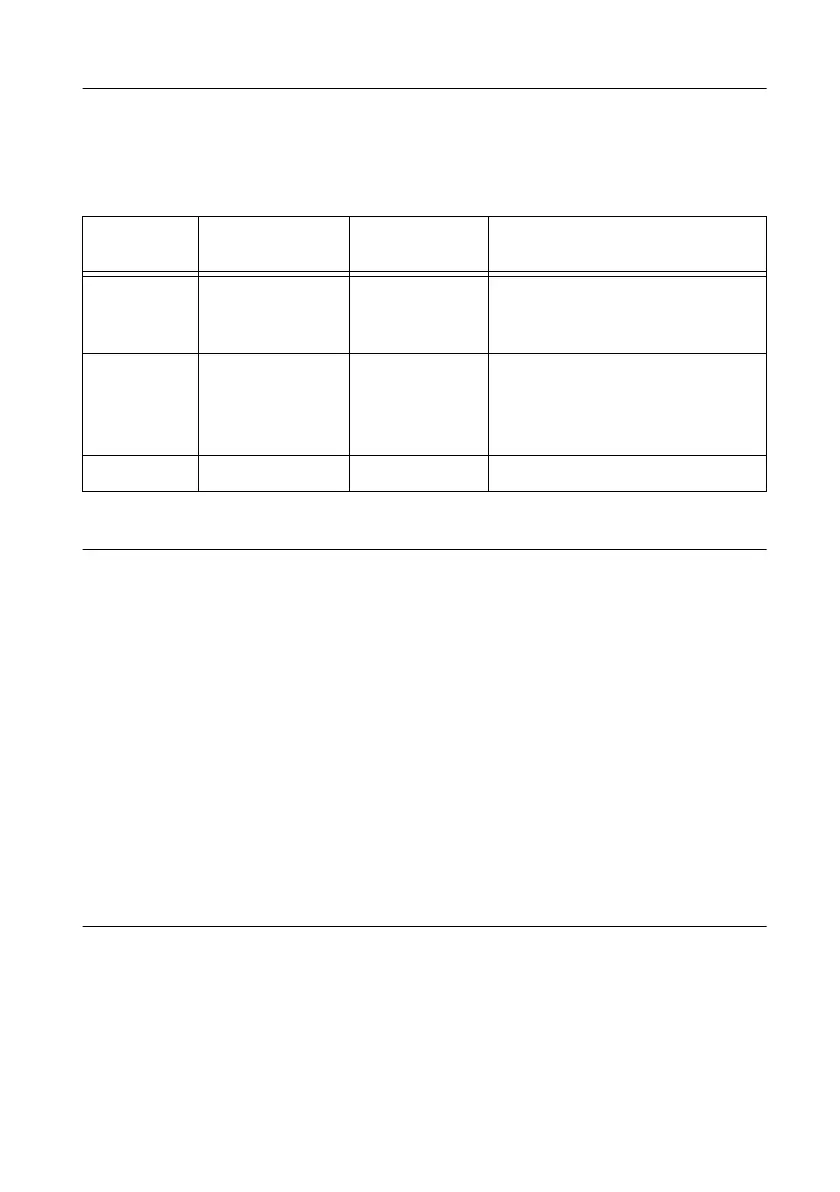

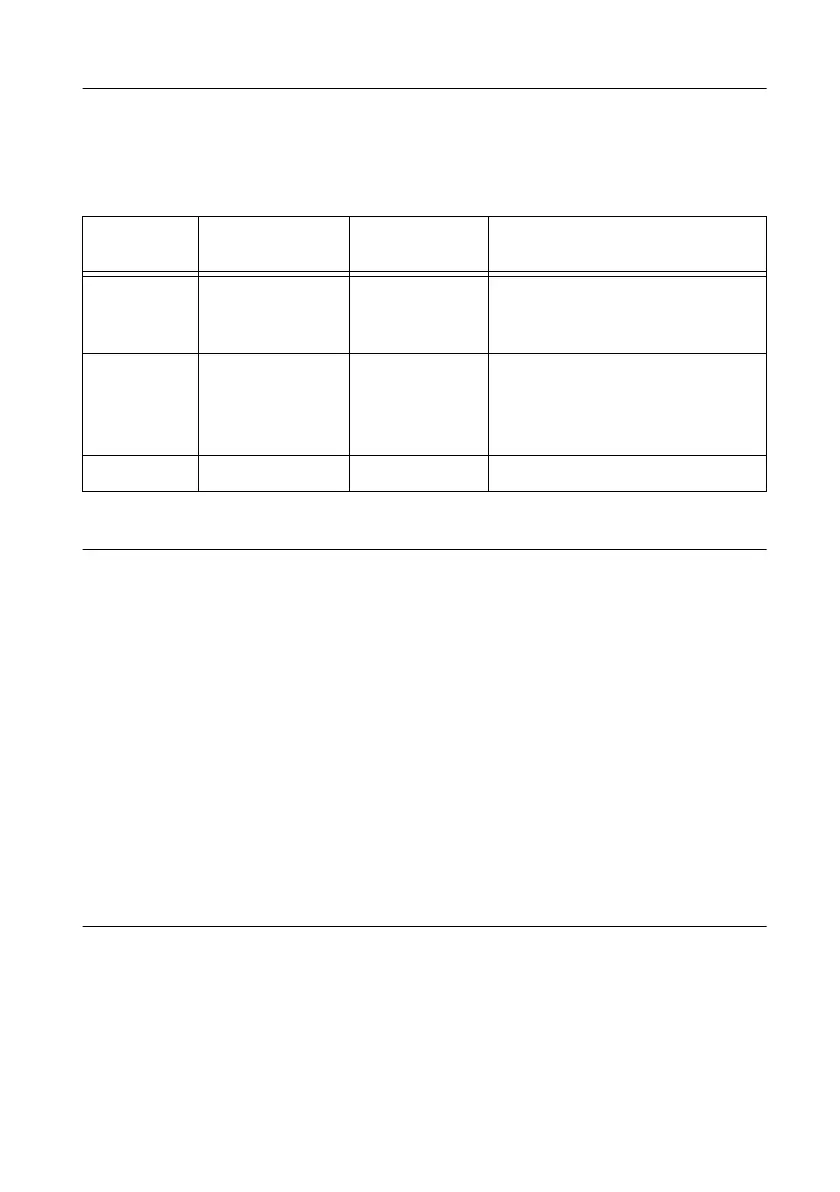

Table 1. Recommended Equipment

Equipment

Recommended

Model

Parameter

Measured

Requirements

Calibrator Fluke 5700A Accuracy,

Adjustment

Use a high-precision voltage source

with an accuracy ≤100 ppm and an

output impedance ≤50 Ω.

Function

Generator

NI 4461 Gain Matching,

Phase Matching

Use a function generator capable of

sourcing both 1 kHz and 20 kHz

±10 V

pk

AC sinusoidal signals with

amplitude uncertainty of ±10%.

Chassis NI cDAQ-9178 All —

Loading...

Loading...