26 NIBE BA-SVM 10-200

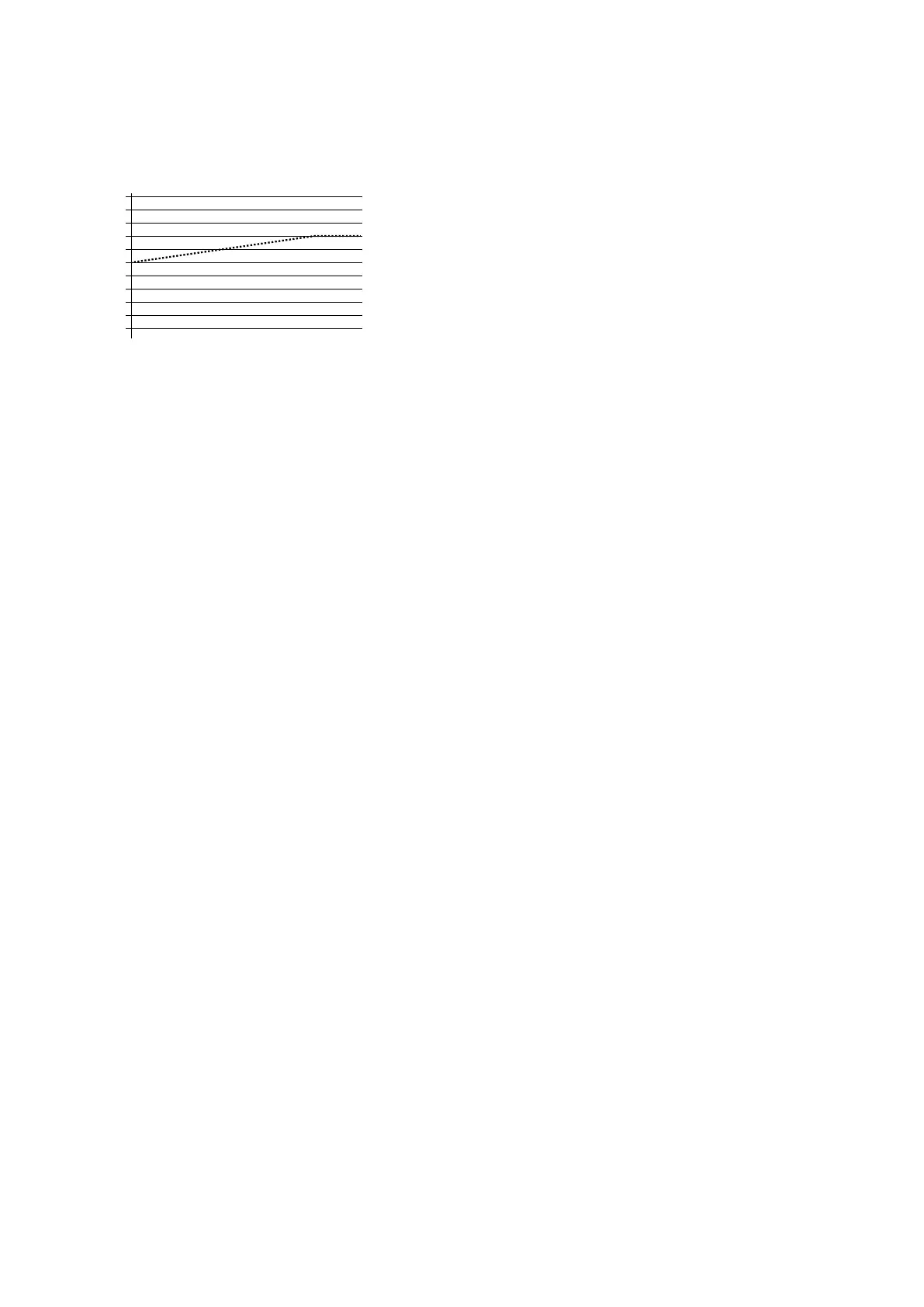

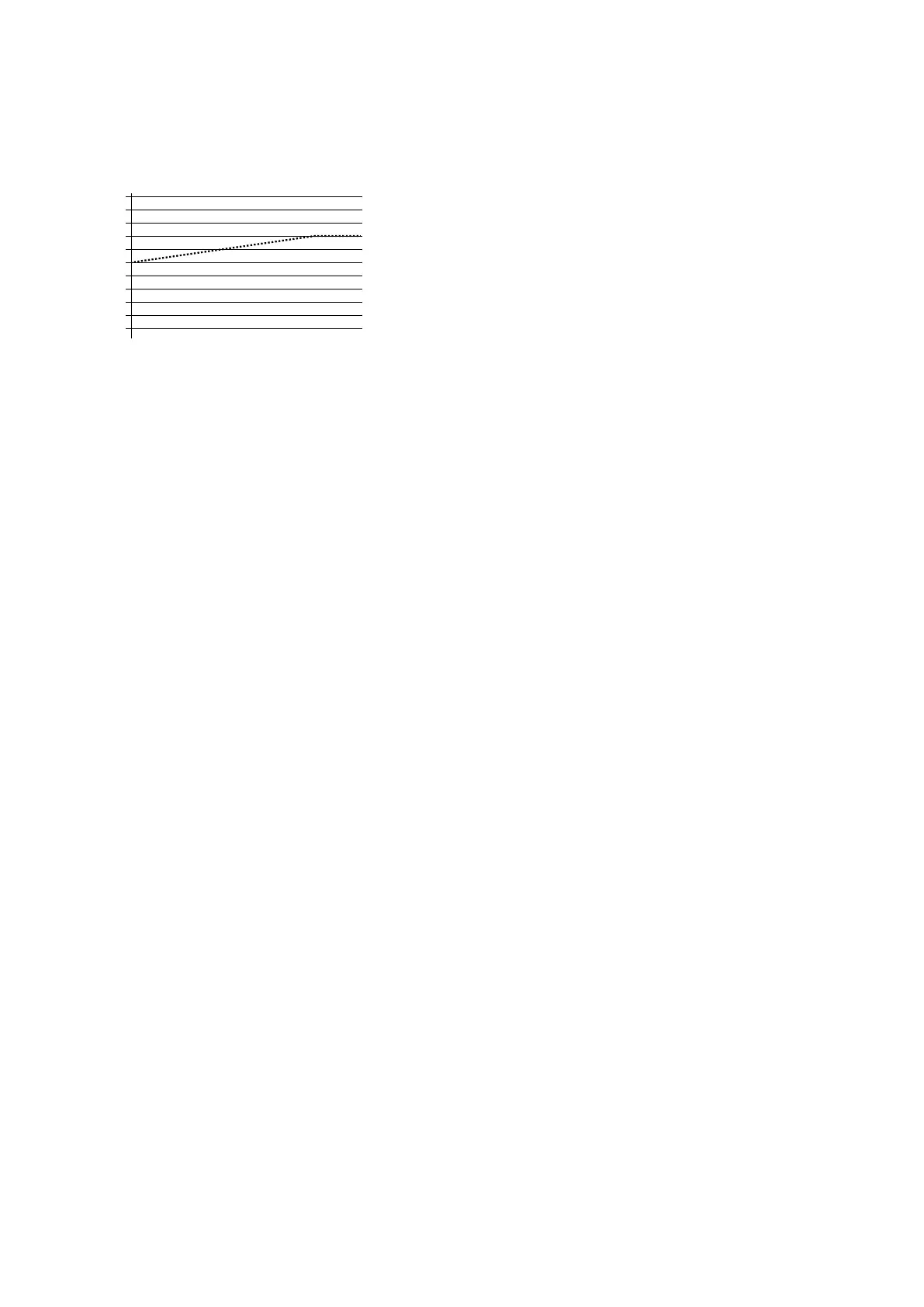

Pump speed at start

10

10

20

30

40

50

60

70

80

90

0

0

-10-20 20

30

Utetemp -EB10X -BT28

% av max speed

Max speed (%)

Outdoor temp -EB10X -BT28 (°C)

Flow settings charge pump GP12

This function is used to check the flow between in-

door and outdoor units. The purpose of the function

is to be able to diagnose the fault in the event of sus-

pected flow related problems.

Program sequence:

• Check that BT6 is less than 40*C otherwise the text

”Drain hot water to cool Water heater” appears.

• Sets reversing valves to HW-mode.

• Starts GP12 and runs at maximum speed.

• Starts the compressor.

For on/off models the following applies: if the com-

pressor does not start within 10 minutes, the flow

setting is cancelled and information is given stating

that the compressor could not be started.

For inverter models the following applies: if the com-

pressor does not start or reach 55 hz within 10 min-

utes, the flow setting is cancelled and provides in-

formation stating that the compressor could not be

started/reach the desired frequency.

For 1-phase inverters, the phase that the 1-phase invert-

er is connected to is detected. A message is given stat-

ing that the 1-phase inverter is being detected. When

the phase has been detected the message ”Compres-

sor detected on phase L?” is shown. If the compressor

could not be detected the message ”Could not detect

compressor phase” is shown. This function may run

during the 5 minutes that the compressor is to run be-

fore the flow checks below are started.

• Ensure that the compressor has run for at least

5 minutes.

• Shows blank screen with 5 minutes countdown.

• Shows highest recommended Δt for the given

outdoor temperature.

• Shows relevant Δt above BT12 and BT13 (the up-

dating frequency is 10 seconds) and calculates an

average value over 10 seconds.

• The user adjusts the flow

• Increase/Decrease the flow indicated in the dis-

play depending on the conditions for the selected

heat pump (slave1)

• When the condition has been met for 1 minute,

”Pump setting OK” appears.

• When the user exits the menu, control of the

charge pump is released again and returns to the

same operating mode as for the setting.

Dimensioned flow for BA-SVM 10-200 is 12 kW at 9

°C. It gives a flow corresponding to 1150 litres. The

coil in the water heater can be deemed to correspond

to the pressure drop in the radiator circuit. For small-

er external parts, AMS 10, 20% less flow than the

dimensioned flow is permitted.

Hot water

If hot water in menu 5.11.1.2 is set to auto, GP12 con-

trols according to ”Determining the speed using reg-

ulator”, otherwise after the manually set speed.

POOL

If pool in menu 5.11.1.2 is set to auto, GP12 controls

according to ”Determining the speed using regula-

tor”, otherwise after the manually set speed.

Defrosting

Any control is stopped

During defrosting the speed is set to a maximum of:

• The average value of the speed GP12 that the

compressor ran to meet the heating demand of

the current defrosting/ manually set speed for

the 2 last minutes.

• 50 %

During tank defrost the speed is set to a maximum of:

• The average value of the speed GP12 that the com-

pressor ran to meet the heating demand of the current

defrosting/ manually set speed for the 2 last minutes.

• 70 %

At completed defrosting:

• If GP12 is controlled, it returns to 30 % higher

speed than it had just before defrosting. The ex-

ception is if priority shift occurs during/in con-

junction with defrosting. This priority shift is then

treated as a normal shift.

• If GP12 is not controlled, GP12 returns to the

speed set for respective demand according to

menu 5.11.1.2.

During passive defrosting:

• GP12 controlled according to operating mode

Auto/Intermittent in menu 5.11.1.2

If GP12 is stationary regardless of operating mode,

the pump exercising function is used.

In emergency mode, GP12 is run without PWM sig-

nal, which means that it runs at maximum speed.

Section 4 | Description of functions

Loading...

Loading...