12 – English

5

STARTING THE AUTOMATION AND CHECKING THE CONNECTIONS

5.1 - Connecting the automation to the mains electricity

CAUTION! – The automation must be connected to the mains electricity by an expert and qualied electrician, in accordance

with established laws, standards and local regulations.

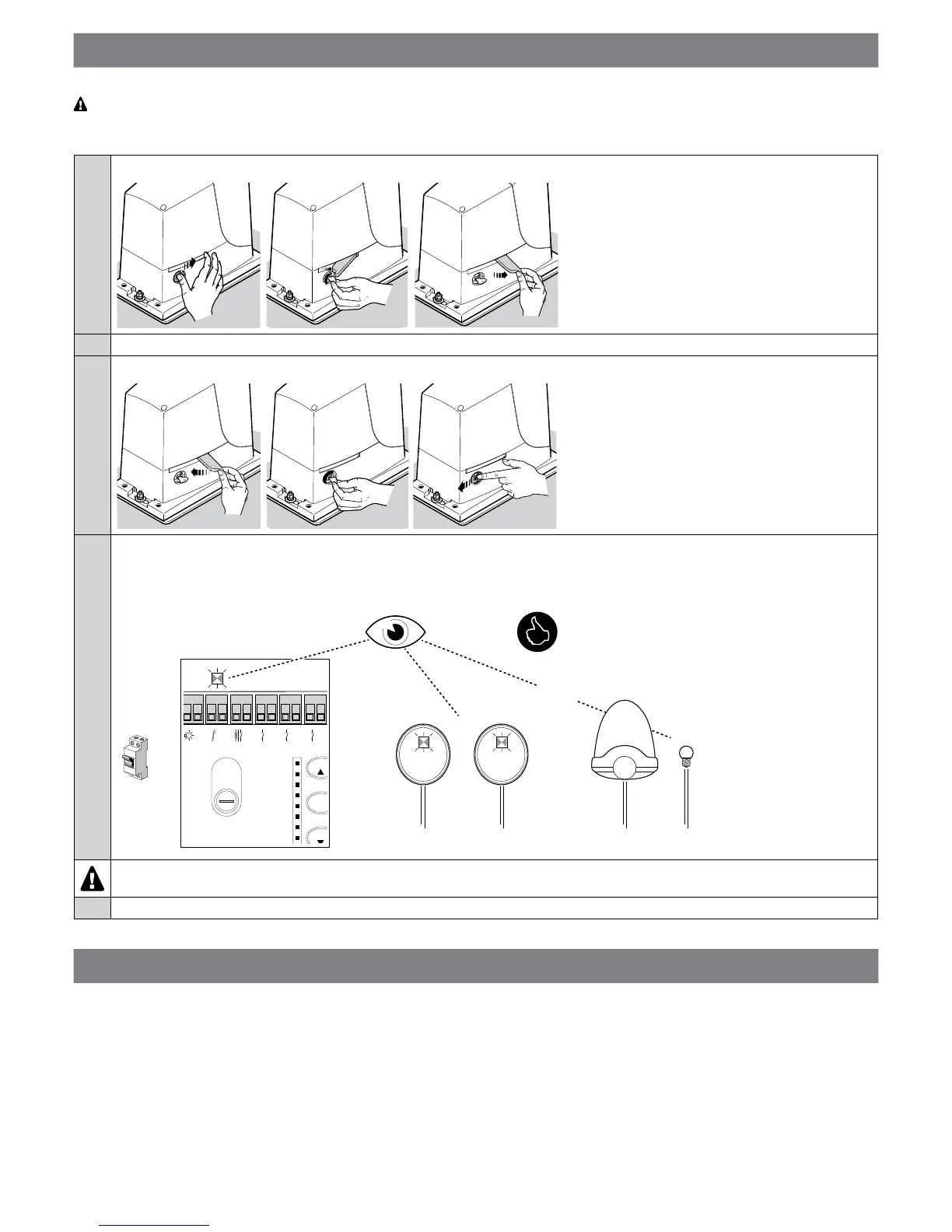

Proceed as described below

01. Manually release the gearmotor so that the gate can be opened and closed

02. Move the gate leaf to the halfway position of its path

03. Manually lock the gearmotor

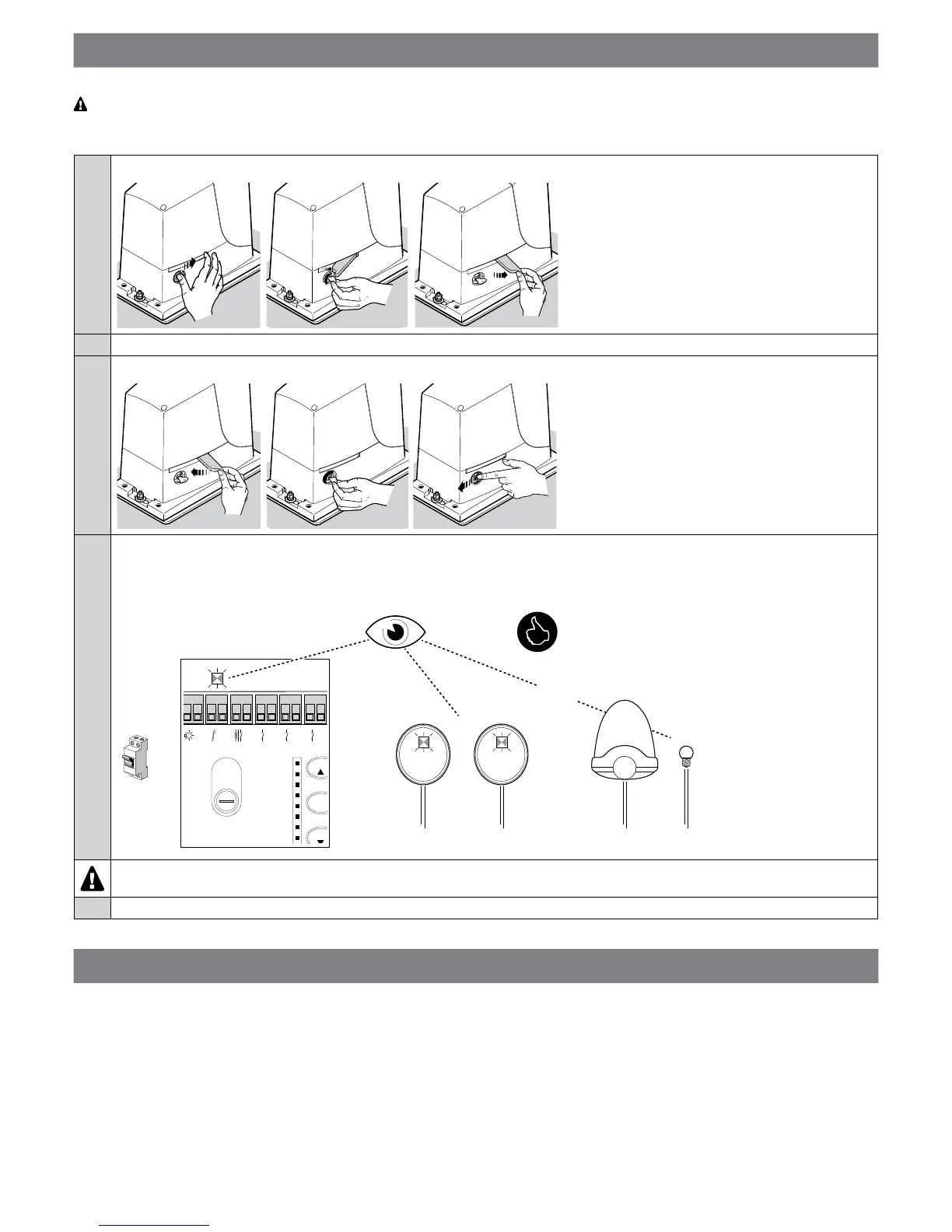

04. power the automation and verify:

- that the BLUEBUS LED ashes regularly at the frequency of one ash per second

- that the LEDs on the photocells ash (both on TX and RX); the type of ashing is not important as it depends on other factors

- that the ashing light connected to the FLASH output and the indicator light connected to the “Gate Open Indicator” output are off

ON

RX

S.C.A

FLASH

TX

OFF

SCA

Bluebus

Stop

PP

Open

Close

if any of these conditions are not satised, proceed as follows (step 05)

05. Shut off the mains power to the automation and check the electrical connections, photocell alignment and fuses

6

TESTING AND COMMISSIONING

These are the most important phases in the automation’s arrangement to ensure maximum system safety.

They must be carried out by a qualied and expert technician who must dene the necessary tests to verify the solutions adopted to counter

any risks present, and check compliance with laws, regulations, standards: in particular, all the requirements of the EN 13241-1, EN 12445 and

EN 12453 standards.

Any supplementary equipment must be tested separately for its operation and for correct interaction with ROBUS: refer to the respective user

manuals.

6.1 - Testing

The testing procedure can also be performed as a periodic check of the automation devices. Each component of the system (sensitive edges,

photocells, emergency stop, etc.) requires a specic testing phase; for these devices, observe the procedures given in the respective instruction

manuals.

Loading...

Loading...