8 Fault elimination

21/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

8 Fault elimination

Risk of injury and poisoning by media

During all work on the valve, wear personal protective equipment.

Any medium leaks must be safely contained and disposed of in an

environmentally-safe manner.

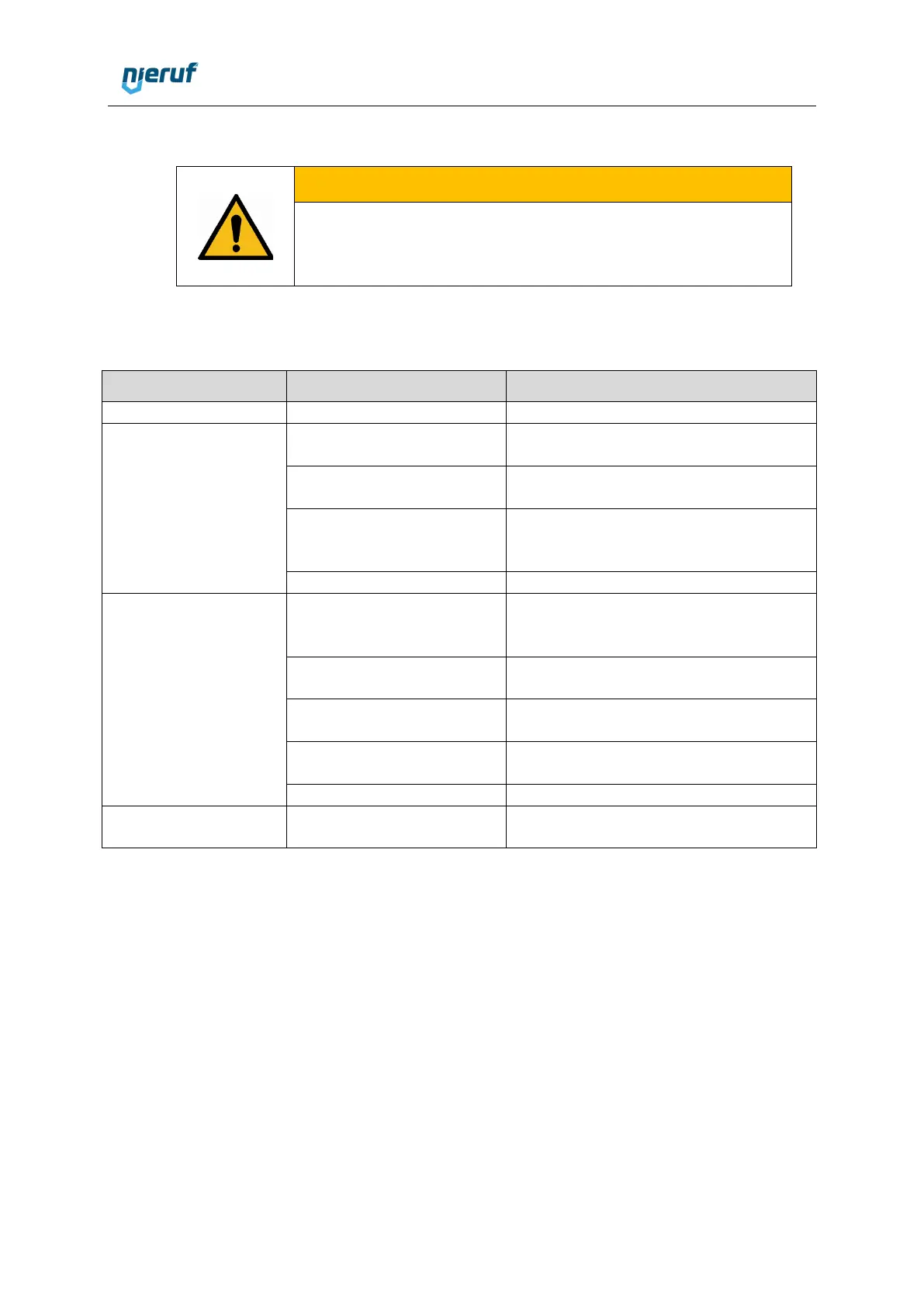

Faults that are not mentioned in the table below or which cannot be attributed to the causes

specified should be discussed with the manufacturer.

Nominal voltage is still

applied

Fit armature to the valve in accordance

with the flow direction.

Differential pressure

between valve inlet and

valve outlet too low

2

Make sure that the required differential

pressure between the valve inlet and

valve outlet is applied.

Operating pressure too high

Check operating pressure and, if

necessary, set permissible operating

pressure.

Supply voltage interrupted

or too low

Check power supply.

Check cable connection.

Nominal voltage and coil

voltage do not match

Make sure that the valve is suitable for

the intended use.

Fit new solenoid coil

(see 7.2.2).

Medium leaking from

pipeline connection

Pipeline connection leaky

Check pipeline connection to the

armature. If necessary, replace the seal.

1) Faults apply to standard valves (NC) normally closed

2) Applies to Type EV04 / MV04 and EV05 / MV05

Loading...

Loading...