Procedure-A:

Insufficient

Cooling,

Compresssor

Runs

Continously

·.· . ,

..

.

..

NOTE

··

· · · . .

'~

-

...

-:,-~·.·'<~•

"'.·-·,,

kO

-,··~--~:~.

>

Measure input voltage(s) before performing this procedure.

Voltage input to

power

supplies must be between the

following range:

VAG

VDC

DE: 85 V min

/132

Vmax

EV:

205V

min

/253

V max.

10.5 to 32 Vdc

A

cAUTION!

Do not short fan wires. Shorting fan wires will

damage the

DC

Power Supply.

1.

Measure voltage across the fan wire harness connector

pins.

II

Refrigerator is operating, fan not running

-voltage

measurement should be negligible.

B Refrigerator is operating, fan running

-voltage

measurement should be between 17 to 22 Vdc.

The

DC Power Supply supplies the fan with 17 to 22 Vdc.

For the fan to turn on the compressor must be running and

the temperature

of

the DC Power Supply must be 95° F

(35° C) or higher.

2.

Test fan operation.

To

test fan, proceed as follows:

a.

Tum

on

refrigerator.

A

cAUTION!

Do

not overheat DC Power Supply! The amount of

heat required to energize the fan circuit

is

minimal.

The fan should come on within seconds.

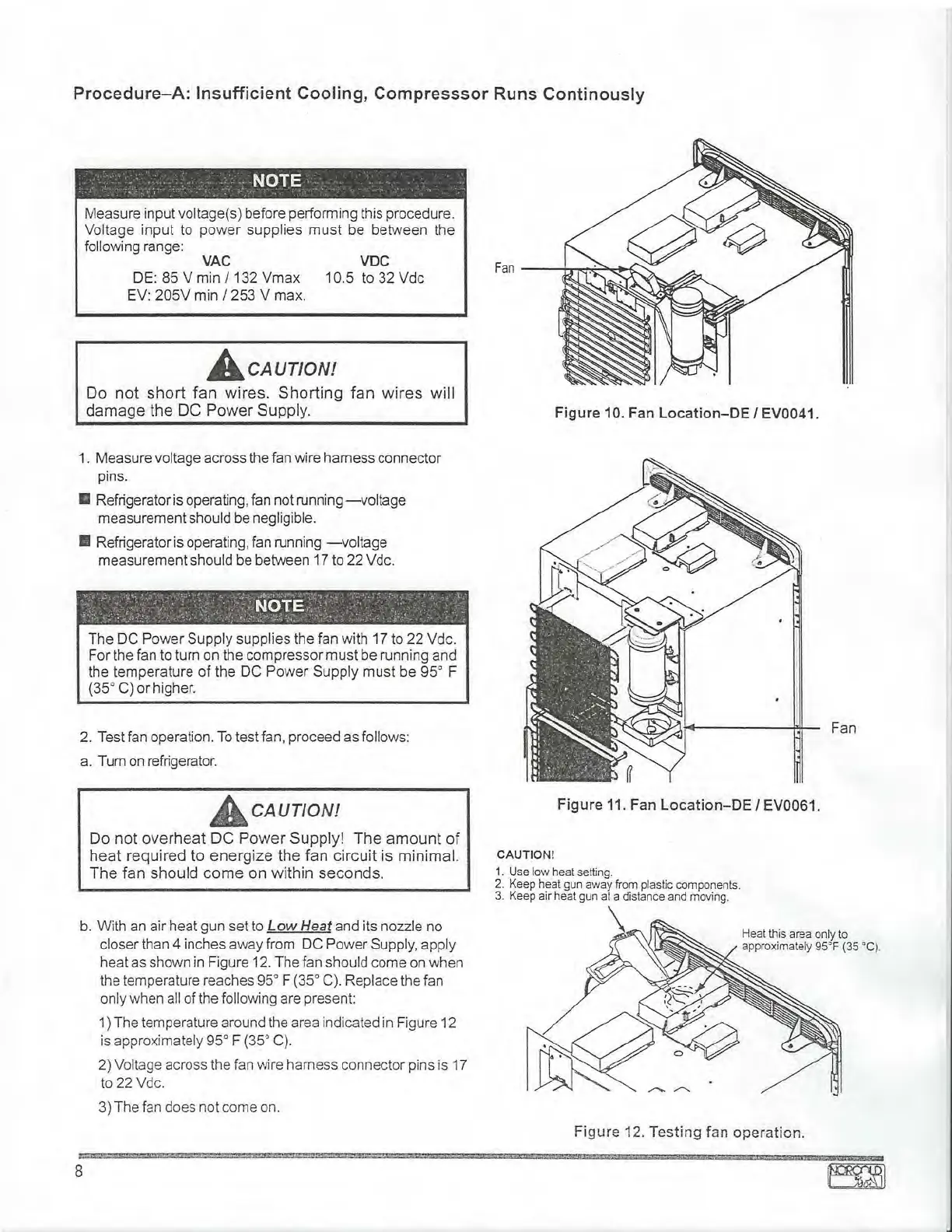

b.

With

an

air heat gun set

to

Low

Heat and its nozzle no

closer than 4 inches away from DC Power Supply, apply

heat as shown

in

Figure 12. The fan should come on when

the temperature reaches

95° F (35° C). Replace the fan

only when all of the following are present:

1) The temperature around the area indicated

in

Figure 12

is

approximately 95° F (35° C).

2) Voltage across the fan wire harness connector pins is 17

to

22

Vdc.

3) The

fan

does not come on.

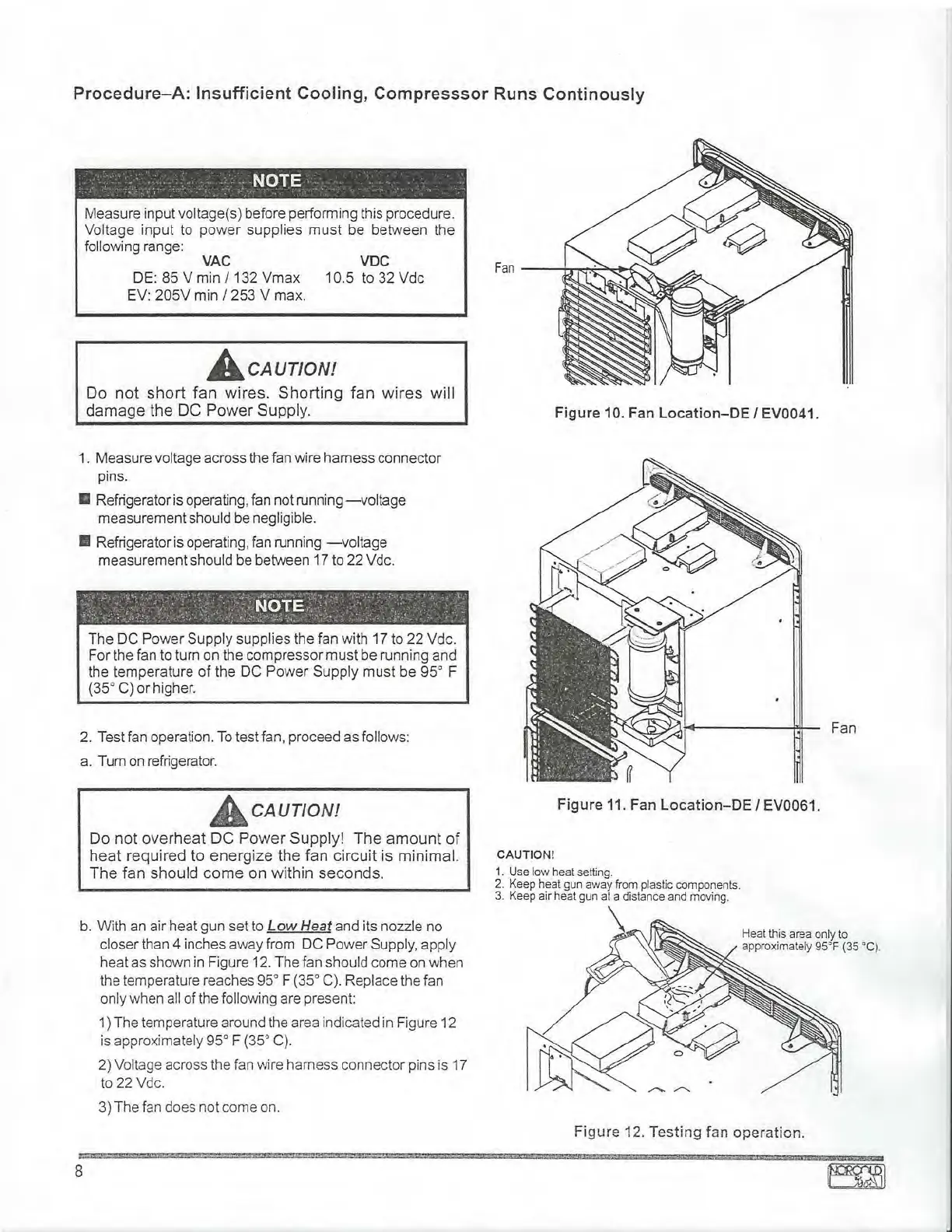

Figure 10. Fan

Location-DE

I EV0041.

Fan

Figure

11.

Fan

Location-DE

I EV0061.

CAUTION!

1.

Use low heat setting.

2.

Keep heat gun away from plastic components.

3.

Keep air heat gun at a distance and moving.

\

Heat this area only

to

approximately 95°F (35

oC).

Figure

12.

Testing

fan

operation.

Loading...

Loading...