Page 28 / 48

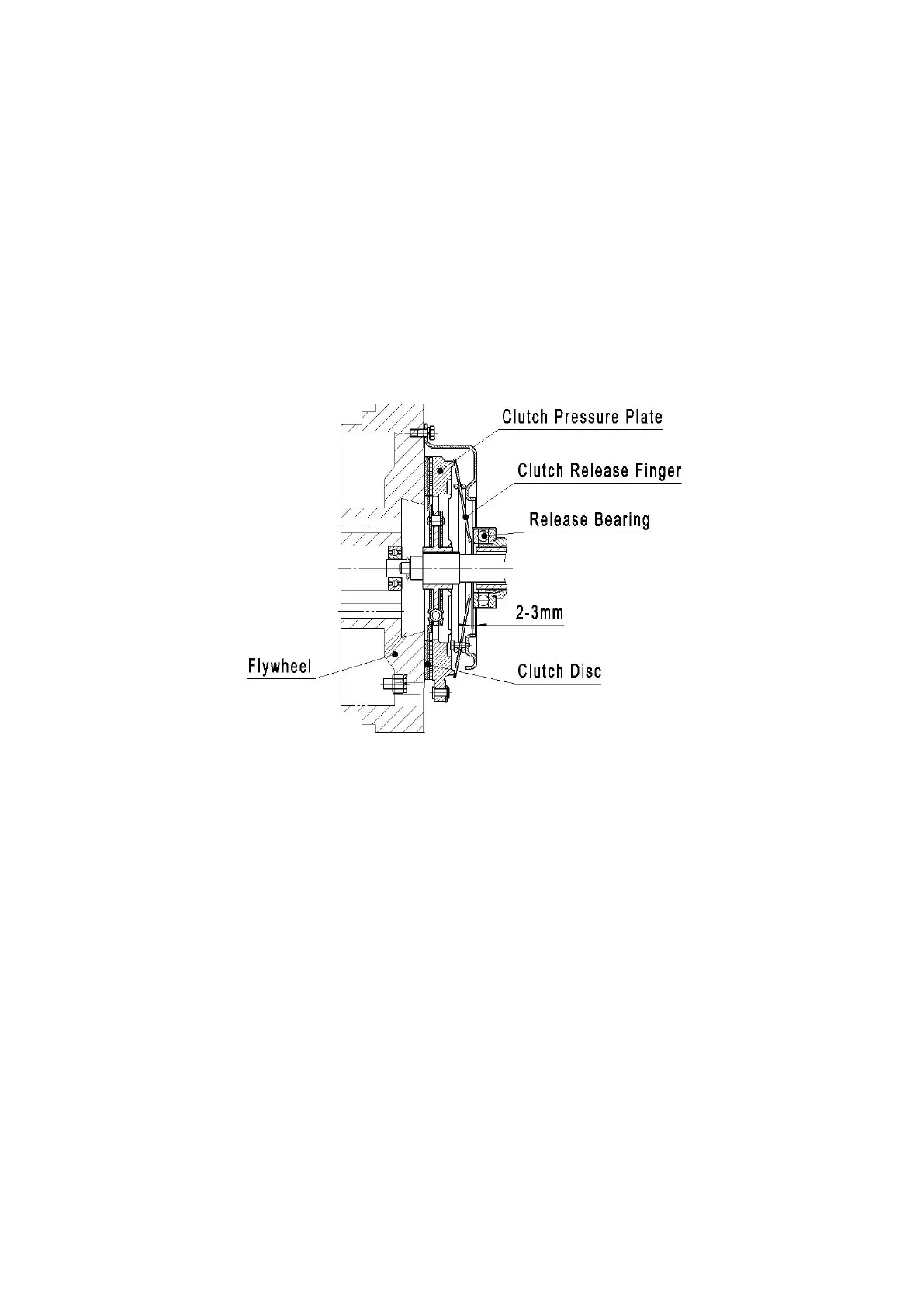

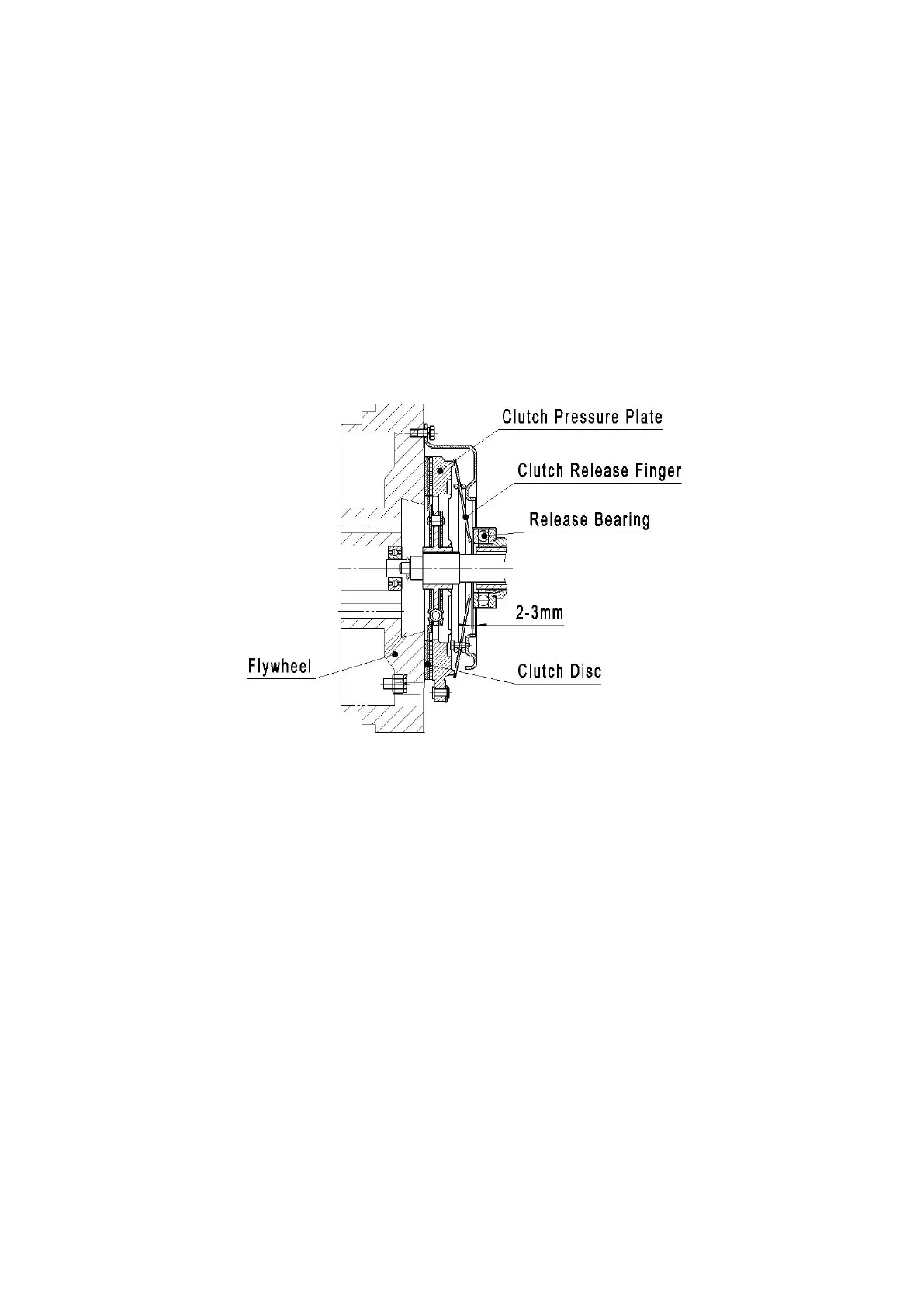

The normal clearance between the surfaces of the clutch release fingers and the clutch release bearing is 2-

3mm (see Fig. 3). When disengaging the clutch, a force is applied on the clutch pedal to eliminate the

clearance. The moving distance of the top of the pedal is called “free play”. It should be 20-30mm. Continue to

press in the pedal, the release rocker moves forward until it reaches the stopper bolt screw. The last straight

distance is called a “working play” and it should be 100-150mm (see Fig. 4).

Adjusting the clutch

When operating the clutch, the wear of the clutch disc and pressure plate causes gradual reduction of

clearance between the release fingers and the release bearing, and even causes some friction between them

which make the free stroke disappear and clutch clip. When this occurs, it’s necessary to check and adjust the

control system (Fig. 3).

Fig. 3

Turn the adjusting fork to shorten or extend the push rod to adjust the free stroke to the stipulated value, and

then screw in or out the stopper bolt to keep the work stroke right. Lock the nuts on the push rod and the

stopper bolt.

Gearbox and Main Drive

Adjusting the First Shaft

1. Place adjusting shims between the first shaft front cover and the gearbox case body.

2. Tighten the first shaft front cover to the gearbox case with four bolts on. The tightened torque should be

30-35Nm.

3. Measure the clearance between the first shaft front cover and the gearbox case body with feeler gauge.

If there is no clearance, put more shims on the primary shaft.

4. Decrease the number of the adjusting shims of the first shaft, and an axial clearance appears. Proper

axial clearance of the first shaft should be 0.05-0.10mm (see Fig. 4).

Loading...

Loading...