Page 29 / 48

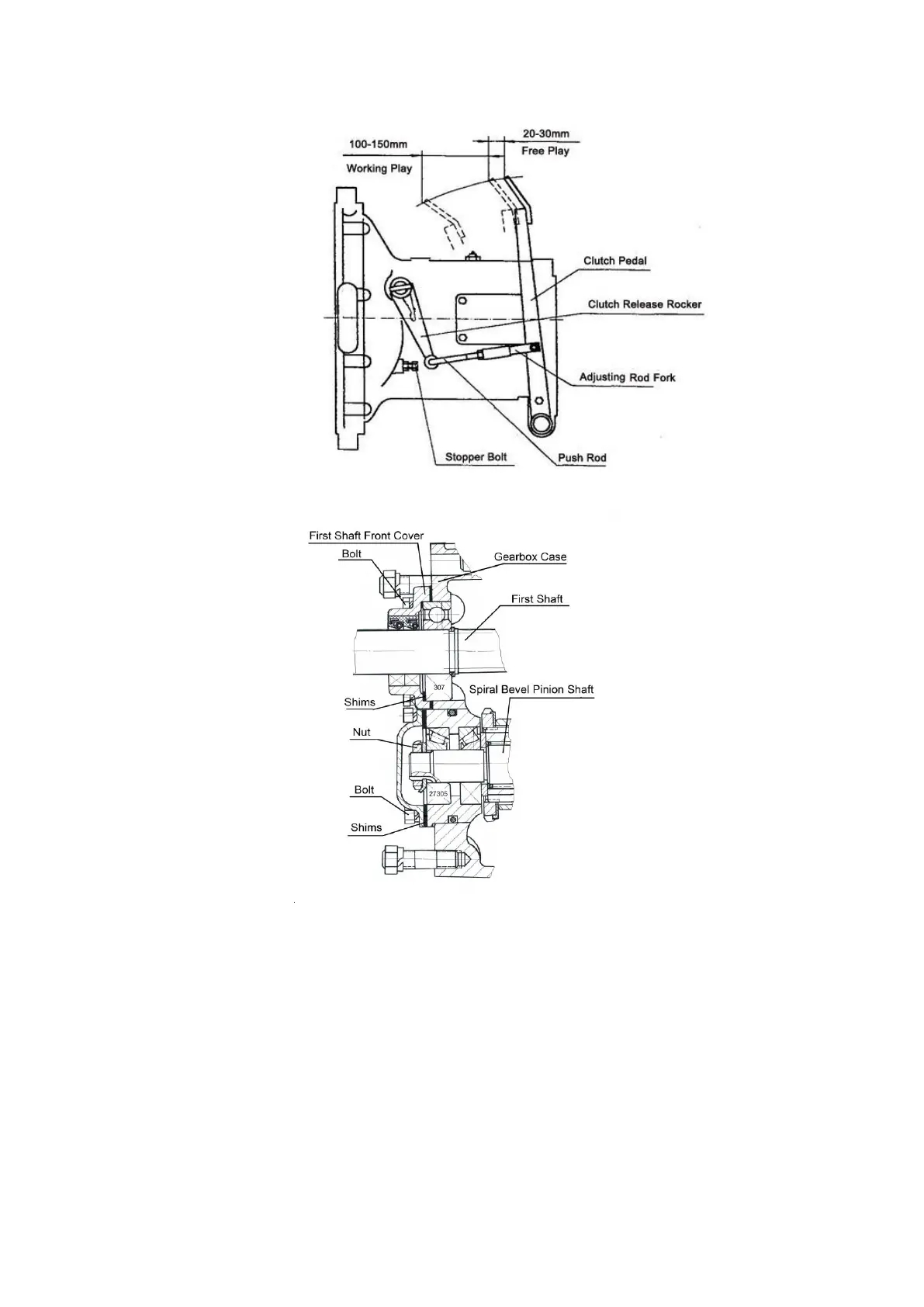

Fig 4.

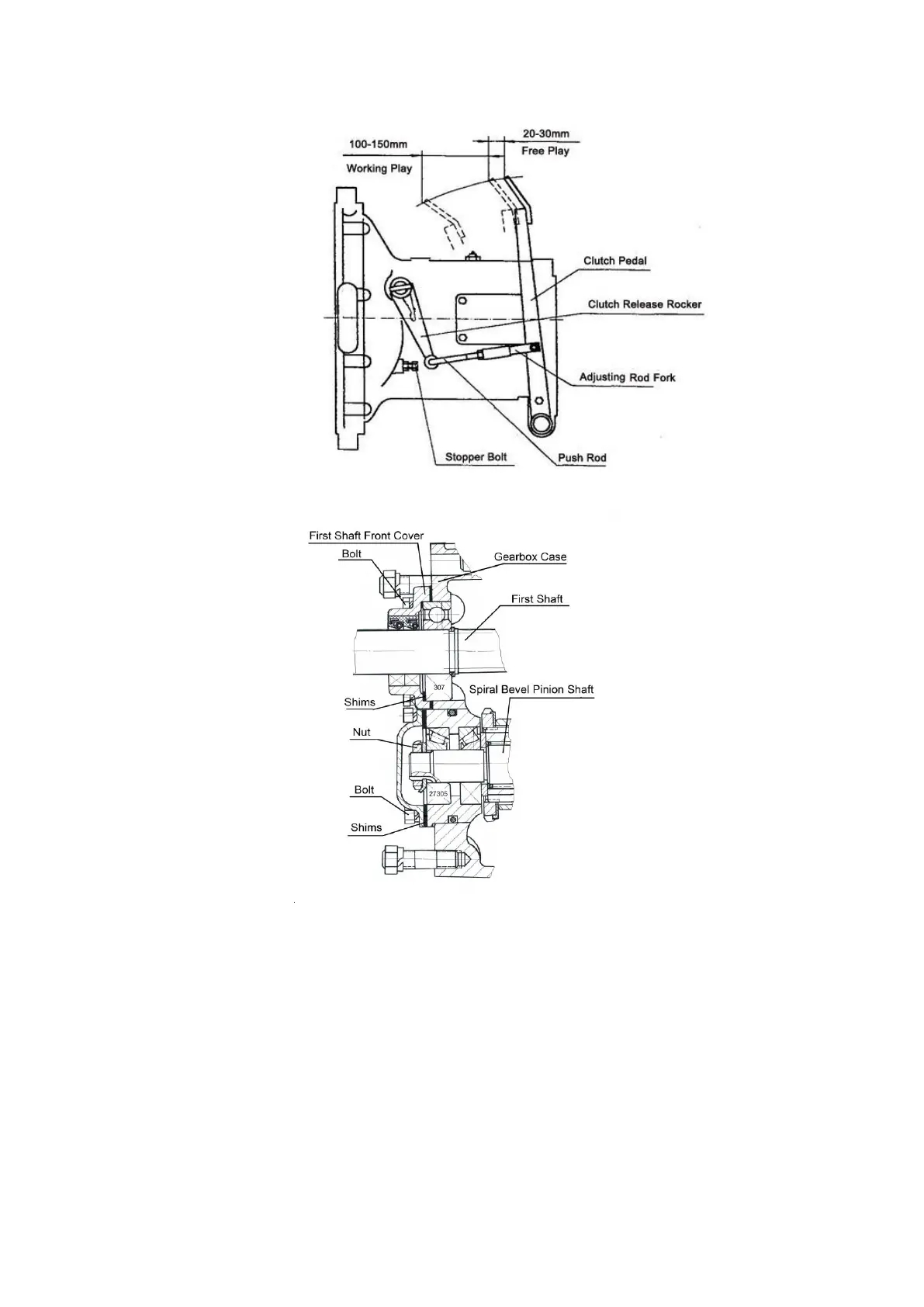

Fig. 5

Adjusting the Spiral Bevel Pinion Shaft

After pre-tightening the spiral bevel pinion shaft’s tapered roller bearing, the measured total friction

torque of the spiral pinion shaft should be 1.0~1.5 mm (see Fig. 4).

Adjusting the Pair of Spiral Bevel Gears

The two spiral bevel gear adjustments should be started after 1-2 minutes of testing in positive and

negative directions, running when there is no oil in the gearbox case. The backlash between two spiral

bevel gears should be 0.15-0.25mm. The ideal imprint is shown in Fig. 7 and Table 1. The imprint of the

spiral bevel gears’ pinion should be higher than that of the spiral bevel gear. With a light load, the length

of the imprint should be about half of the total length of the gear tooth. When shifting to the larger end

of the gears with a full load, the imprint of the gears should approach the small ends while installing

inspection. The adjustment of a pair of spiral bevel gears under various condition is shown in Table 1.

Loading...

Loading...