Page 31 / 48

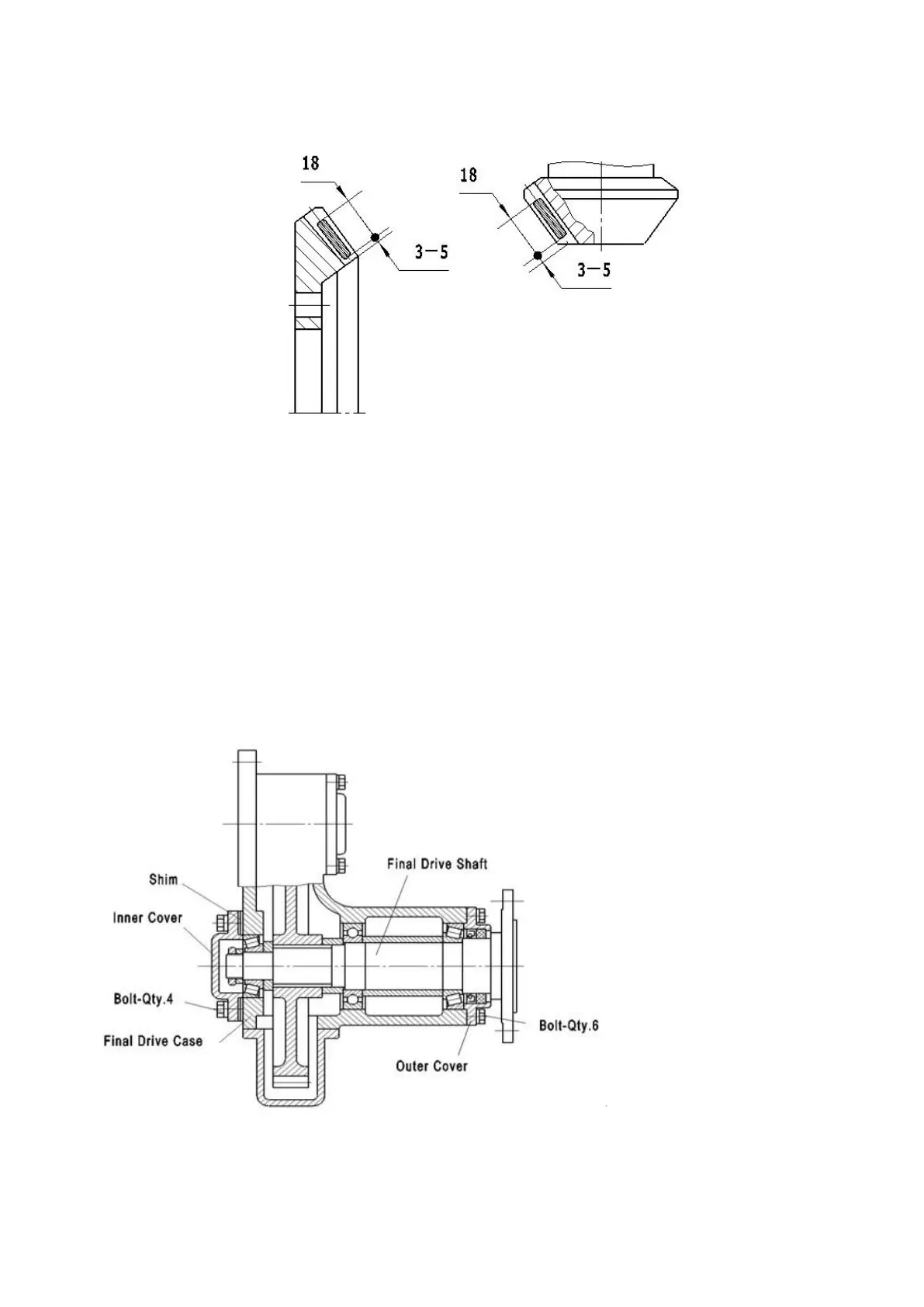

Fig. 6

The imprint of spiral bevel gears pair adjustment will be implemented by increasing or decreasing the number

of shims of the spiral bevel pinion shaft and nuts adjustment on both sides of the bevel gear. At the same time,

the adjusting nuts are also used to pre-tighten the tapered roller bearing of the main drive shaft. After pre-

tightening the tapered roller bearing, the rated total friction torque of the bevel gear shaft should be 0.7-1.0Nm.

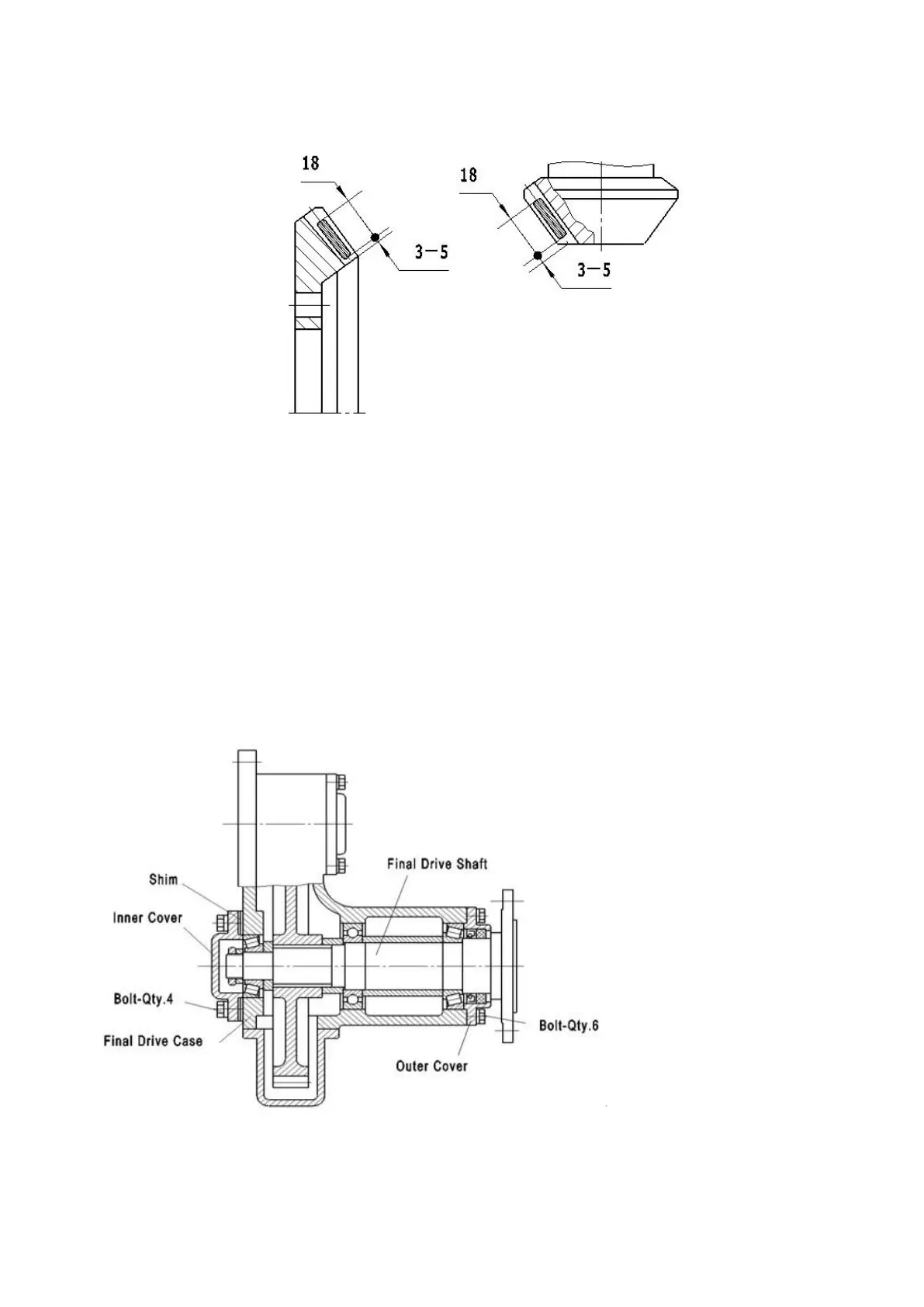

Final Drive

1. Tighten the outer cover of the final drive case with six bolts. The rated torque should be 30-35Nm.

2. Tighten the inner cover of the final drive case with four bolts. The rated torque should be 35-40Nm.

3. Measure the clearance between the inner cover and the final drive case body with the feeler gauge. If there

is no clearance, decrease the number of the shims of the final drive shaft.

4. Place the correct number of adjusting shims into the gap between the inner cover and the case body. The

clearance should be 0.03-0.10mm (Fig. 6).

Fig .7

Brake and Steering Clutch Control System

Loading...

Loading...