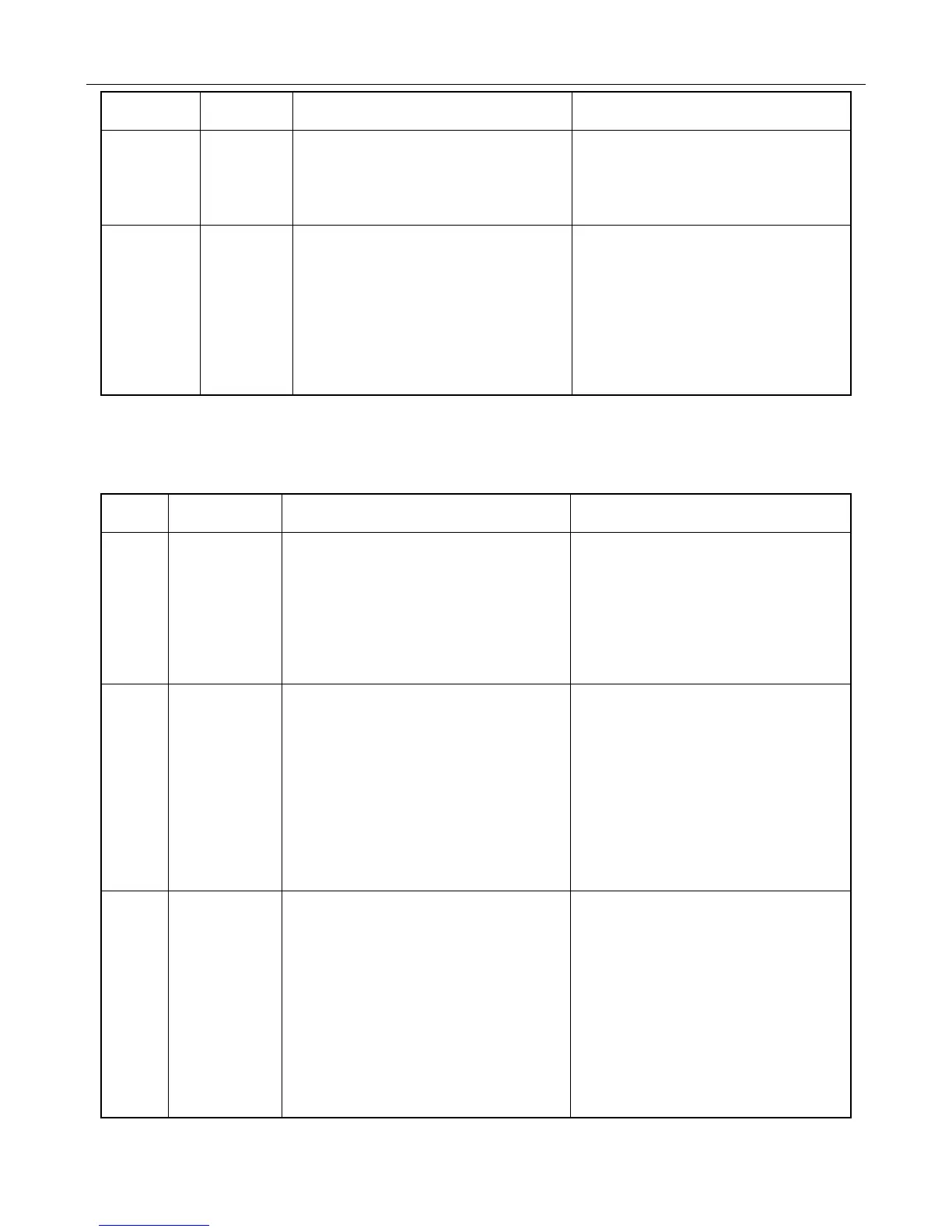

Operation Description

40

Sequence

No.

Fault Fault Reasons Troubleshooting

lift position

the

distributor

emits a

loud noise.

the lifter case to open the safety

valve.

the force/position adjusting rod to

make the lift height lower that the

original position.

6

Hydraulic

lifter has

no

hydraulic

output or

weak

output.

(1) The oil inlet pipe of the oil cylinder

is cut off.

(2) Front cone and conical hole of

speed lowering control valve have

not been sealed tightly.

(3) Lifter is in the neutral lifting

position.

(1) Fasten the control handle to lower

the speed.

(2) Replace the valve.

(3) Push the lifter control handle to the

lowering position to lower the

outer lifting arm to the lowest

position. Shut off the inlet oil line

to the oil tank, then put the

operation handle in the lift position.

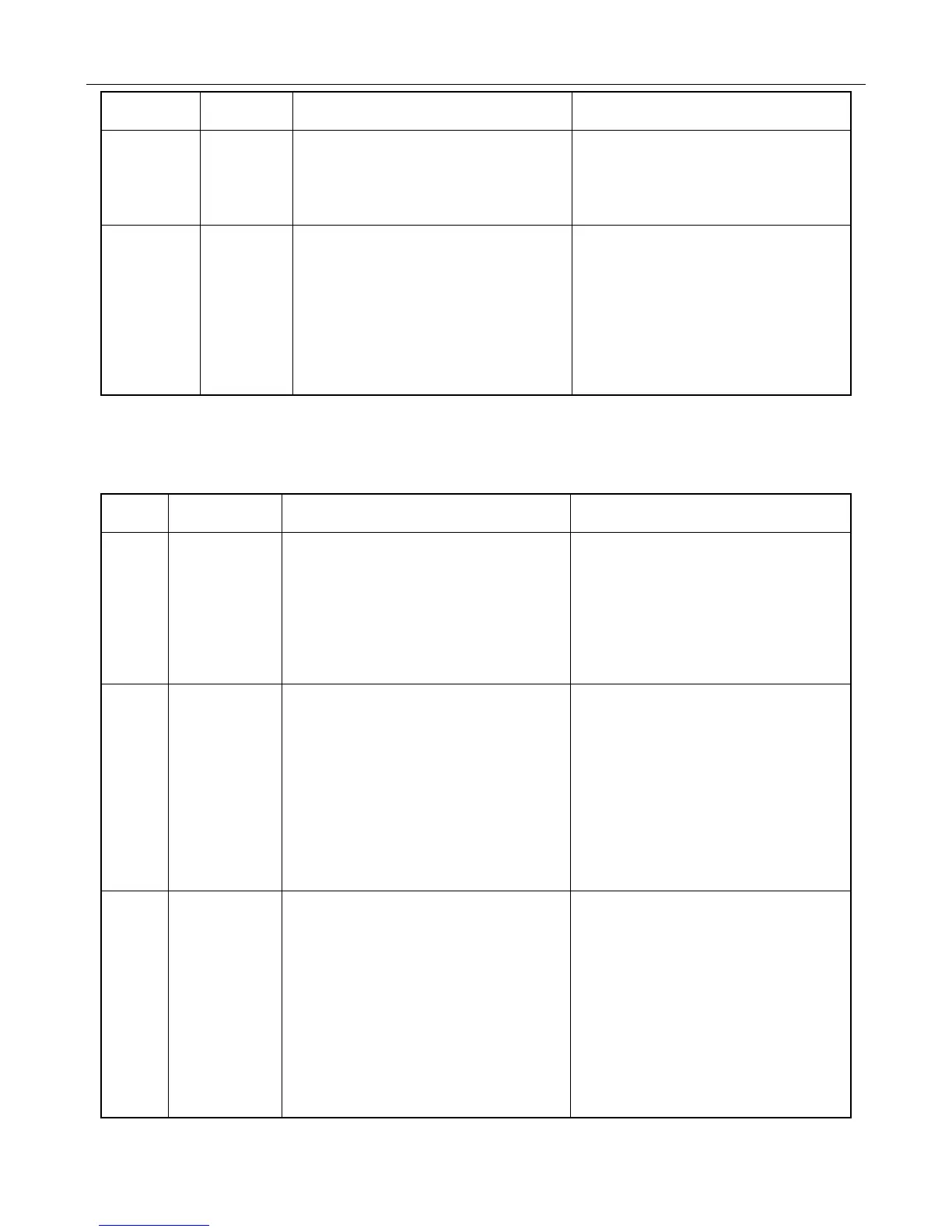

2 .16.2 Electrical System Fault and Troubleshooting

2.16.2.1

Starter Faults and Troubleshooting

Table 2-11 Starter Faults and Troubleshooting

Sequence

No,

Fault Fault Reasons Troubleshooting

1.

The starter

doesn’t work.

(1) Battery capacity is insufficient.

(2) Battery pole is dirty or the cable is

loose.

(3) Cable connector is loose.

(4) The wires in control circuits such as

the start switch are broken.

(5) No contact between the carbon brush.

(6) Circuit broken or a short in the starter.

(1) Charge the battery according to the

specifications.

(2) Remove dirt and tighten the

connecting parts.

(3) Tighten connectors.

(4) Check circuit and connection.

(5) Replace starter.

(6) Replace starter.

2 Starter failure.

(1) Battery capacity is insufficient.

(2) Poor wire connections.

(3) Rectifier surface burnt or

contaminated by oil.

(4) The carbon brush is worn or the spring

pressure is insufficient.

(5) Bad contact with rectifier.

(6) Main contact of the solenoid switch is

burned, resulting in a poor connection.

(7) Bearing severely worn. Armature rubs

against the case.

(1) Charge the battery.

(2) Tighten the wire connections.

(3) Replace commutator or remove the

oil stains.

(4) Replace

(5) Replace.

(6) Replace.

(7) Replace

3

After the engine

has been started,

it continues to

run, but emits a

sharp noise.

(1) Circuit breaker copper contact disc and

the two contacts on the starter are

stuck.

(2) Starter lever disengaged or loose bolts.

(3) Lever return spring is broken or loose.

(4) Starter motor armature shaft is broken

or bent.

(5) Tooth surface snapped or locked.

(6) Contact(s) of the starting relay are

stuck.

(7) Igniting switch doesn’t return

automatically after starting.

(1) Replaces tarter

(2) Readjust or replace.

(3) Replace starter

(4) Replace starter

(5) Replace starter

(6) Replace starting relay.

(7) Replace igniting switch.

Loading...

Loading...