TROUBLESHOOTING

NOVA Lock & Load

TM

Owner’s Manual

11

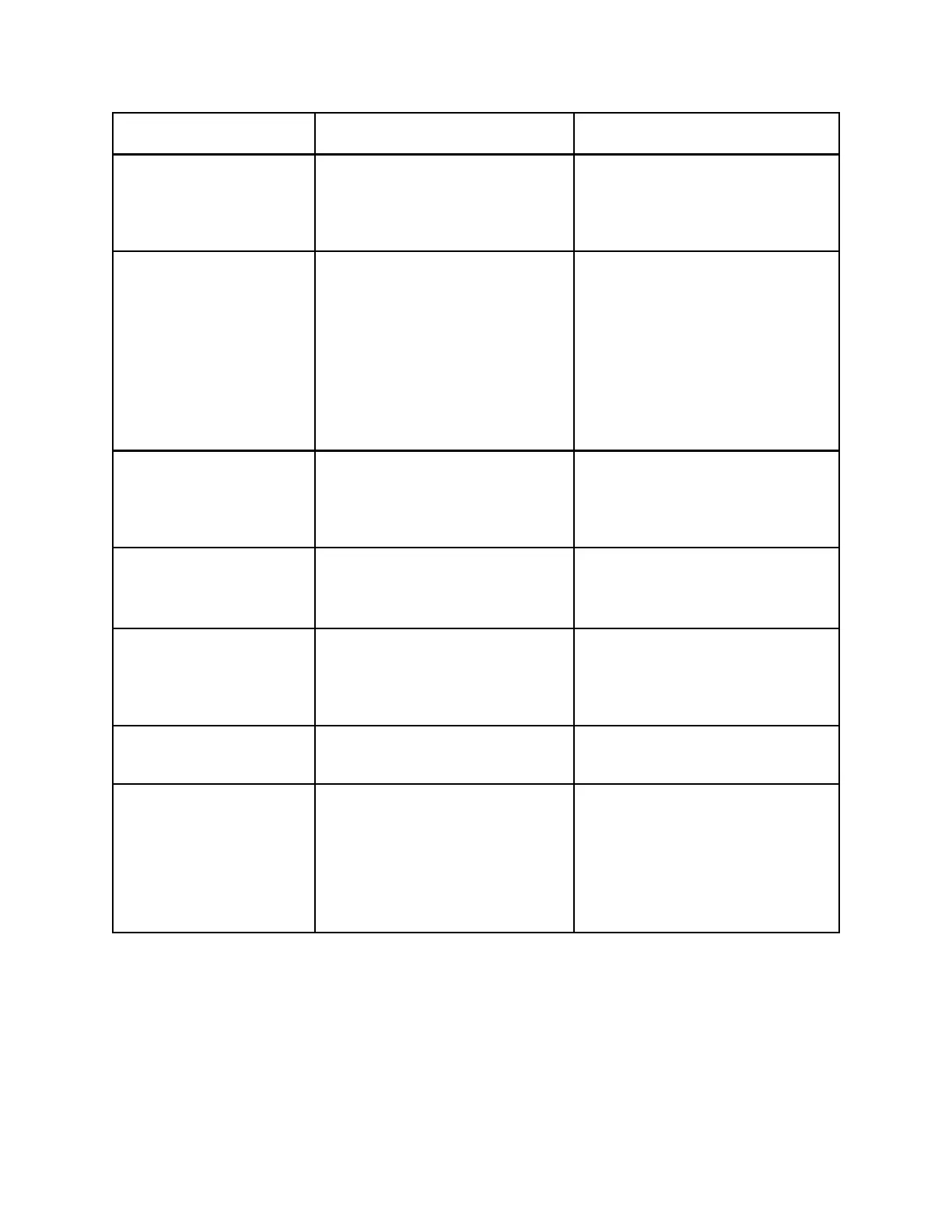

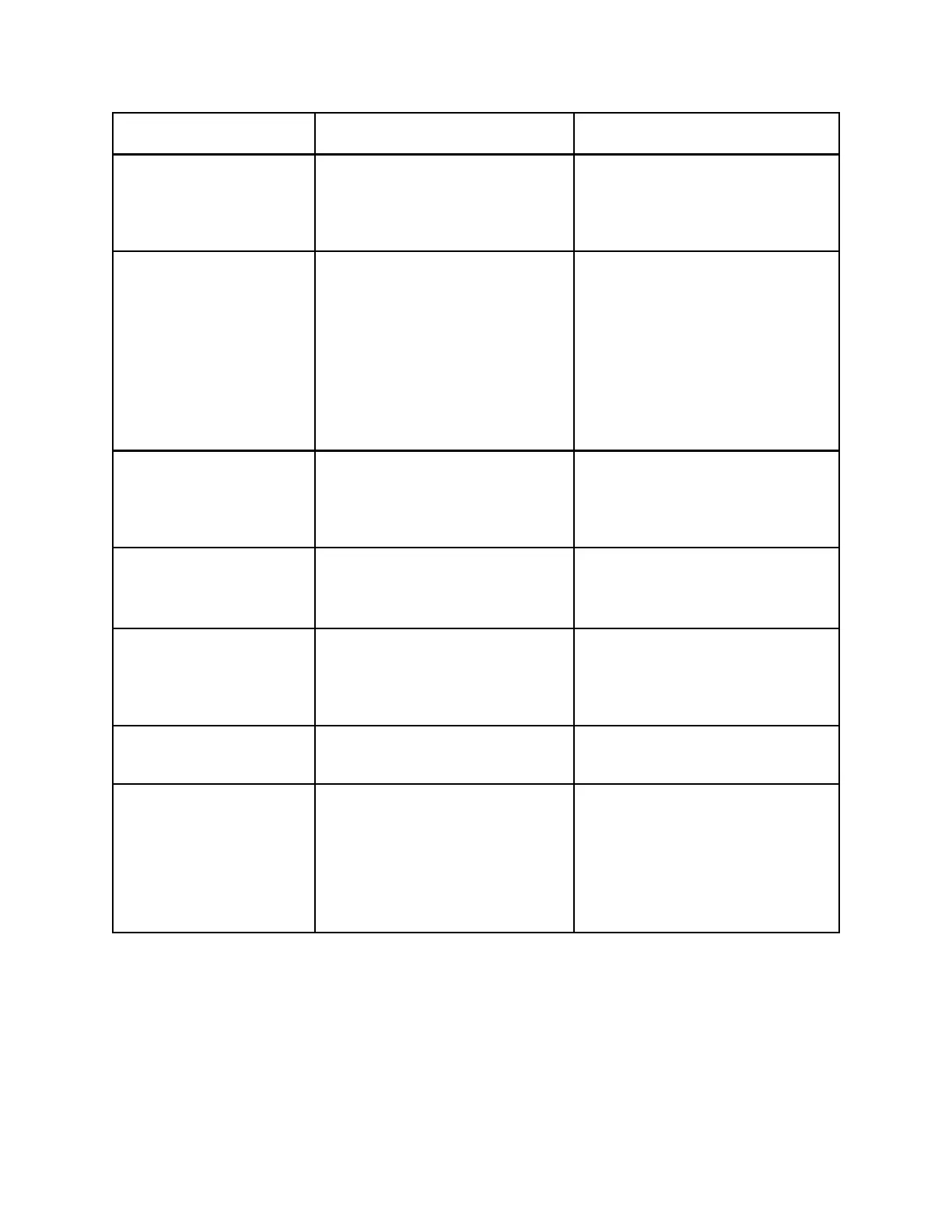

PROBLEM PROBABLE CAUSE RESOLUTION

Lock & Load vehicle restraint

lights do not flash and the

hook does not raise.

Power source malfunction.

Incorrect wiring.

Check power source, including facility

circuit breaker and 1A fuse. and

circuit breaker on power module.

Verify wiring per Electrical Schematic,

Figure K page 14.

Lock & Load vehicle restraint

lights are flashing, but the

hook does not raise or lower to

full extent.

Chain is loose or broken.

Low incoming voltage.

Drive motor defective.

Incorrect wiring.

Adjust or replace as required.

Verify incoming voltage at L1 and L2

is a minimum of 110V. Do not power

off a control transformer from other

equipment unless properly sized for

load.

Check motor. Repair or replace as

needed.

Verify wiring per Electrical Schematic,

Figure K page 14.

Lock & Load vehicle restraint

is operational, but hook drops

causing lights to change and/

or horn to sound while trailer is

being serviced.

Verify brake torque.

Drive motor defective

If brake torque is less than 500 in lb or

chain is loose or broken, adjust or

replace as required.

Check motor. Repair or replace as

needed.

Lock & Load vehicle restraint

is operational but all lights are

out.

Bulbs burnt out, loose or missing.

Incorrect wiring.

Check all bulbs and replace as re-

quired.

Verify wiring per Electrical Schematic,

Figure K page 14.

Lock & Load vehicle restraint

horn does not sound but hook

and lights are operational.

Horn is defective.

Incorrect wiring.

Power horn using 12V DC power. If

horn does not sound, replace as re-

quired.

Verify wiring per Electrical Schematic,

Figure K page 14.

Lock & Load vehicle restraint

hook is in stored position with

an inside green light.

Incorrect wiring. Verify wiring of SW1 and SW2 at the

control box and outside junction box.

Lock & Load vehicle restraint

carriage does not return to a

full up position

Carriage binding in track.

Damaged roller track plate.

Broken or weak springs.

Check to see if roller track plate is

clean and rollers are clean, full of de-

bris and lubricated. Use only ap-

proved grease to lubricate rollers.

Verify that the roller track plate is

straight and not damaged.

Remove spring cover and replace as

required

Loading...

Loading...