116 OPI_SMART LIFT 2.30 SL-2.35 SL-2.40 SL - HYMAX S 3000-S3500-S4000_V1.2_DE-EN-FR-ES-IT

• Make sure that there is no residue of the cleaner

on the lift.

• Dry the lift with a cloth and spray it with a spray

waxoroil.

• Moving parts (bolts, bearing zones) are to be lu-

bricated or oiled according to instructions.

• Whencleaningtheworkshopoorensurethatno

aggressive cleaning materials come into contact

with lift surfaces. Permanent contact with any

kind of liquid is prohibited.

7.3 Readjustmentofthepolyexbelt

When exchanging the drive belt, the belt tension

must be readjusted. For this, remove the v-belt cov-

er.

Figure 12: V-belt cover

(version with riser)

1: Column

2: Riser

3: V-belt cover

4: Lift spindle

Subsequently the v-belt tension on the tensioning

elementisreset(gure14).Forthis,the3fastening

screws of the motor (Figure 14, no. 1) are slightly

relaxed by one rotation. On the adjusting screws

(Figure14,no.2)thev-beltcannowberelaxedor

tensioned accordingly.

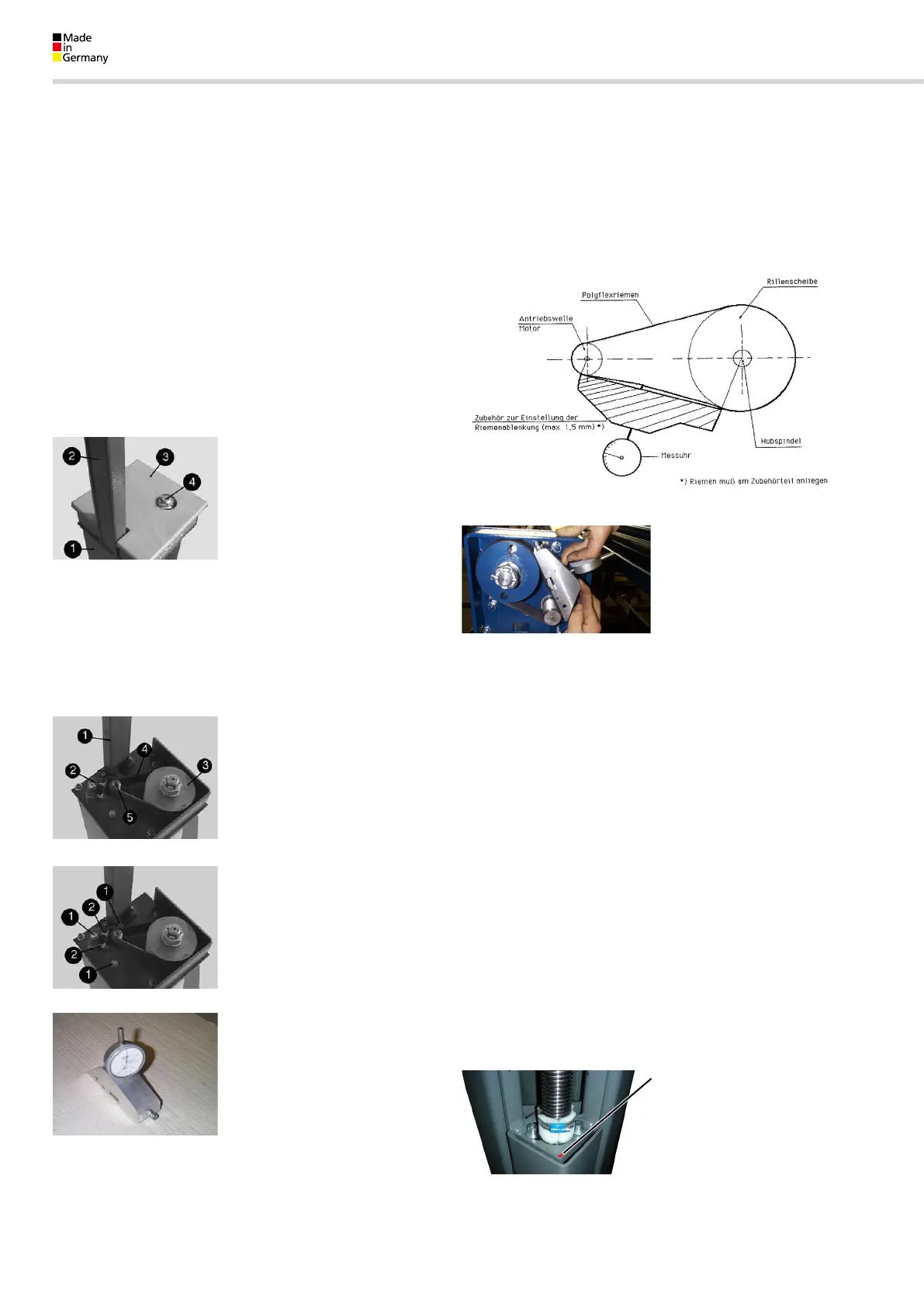

Figure 13: Position of the drive belt

1: Riser; (optional)

2: Tensioning elements to readjust

the belt tension;

3: Grooved pulley;

4: Polyex belt (drive v-belt)

5: Drive shaft motor

Figure 14: Setting the v-belt tension

1: Motor fastening screws

2: Alignment screws for v-belt ten-

sion

Figure 15: Accessory part

The polyex belt is set to the corresponding belt

deection with the aid of accessory parts (Figure

15); to be purchased from Nußbaum Hebetechnik

GmbH & CO.KG.

• Before setting the v-belt, the measurement de-

vice is to be placed on a at solid surface and

pusheddownwardsuntilthestylusislayingaton

the smooth surface.

• Afterwards null the dial gauge, meaning the outer

ring of the dial gage is to be turned so the pointer

is at zero.

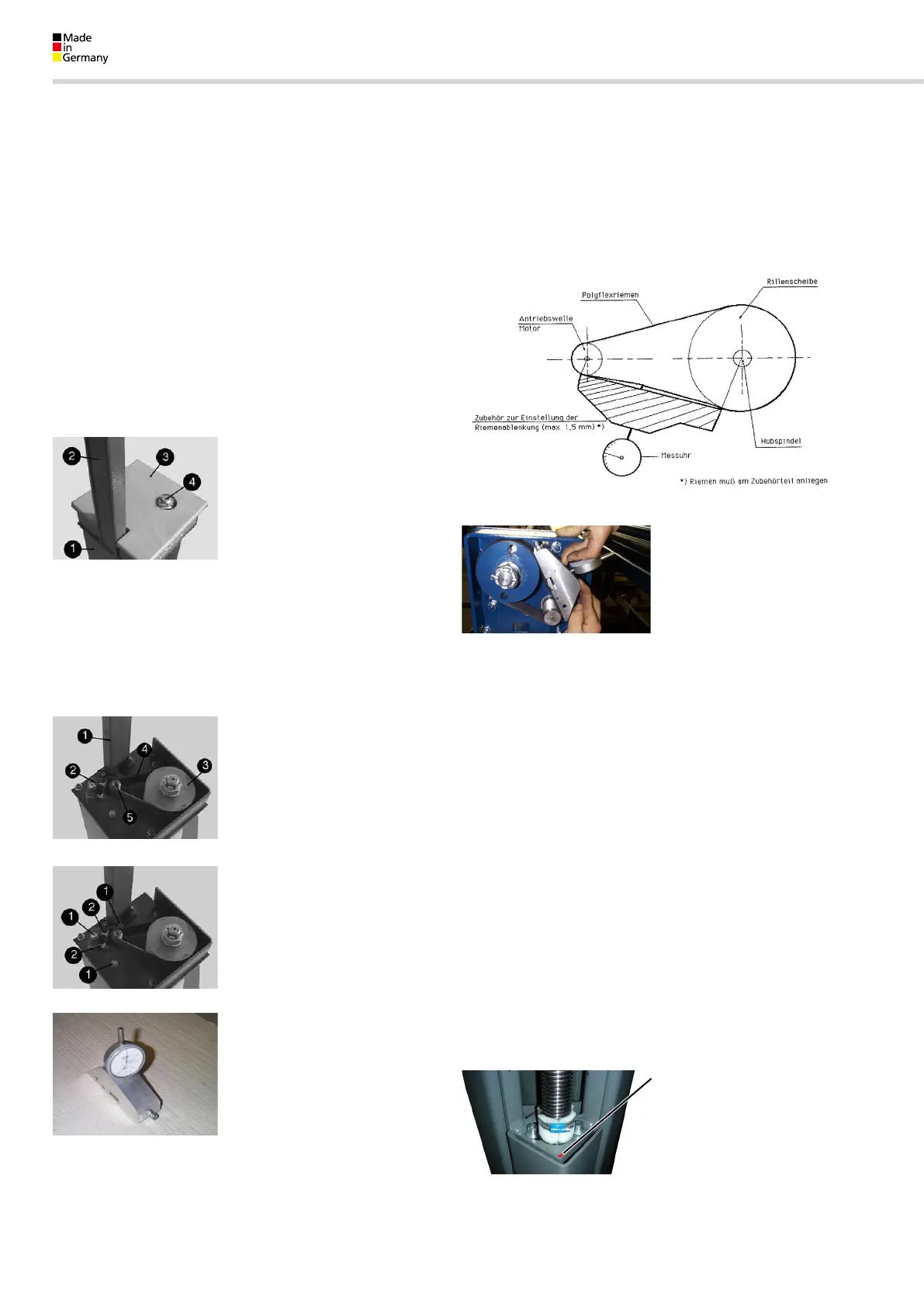

Figure 16: Measurement instrument

Figure 17: Place the dial

gauge on the belt

• The measurement device, as can be seen in Fig-

ures16and17onthepolyexbelt.

• The dial gauge may only be turned a minimum of

1rotation(1mm)toamaximumof1.5rotations

(1.5 mm) anti-clockwise.

• The fastening screws are to be placed into the

starting position again.

7.4 Check/exchangetheliftnutsystem

Optical wear measurement:

! Catchbarxation“Safetykit”mustbeintegrat-

ed, see Section 9.1.

To check the carrier nut, the cover of the lift spindle

must be removed. A carrier nut wear gauge pin is

integratedintothecarrierplate.Thismustbeush

with the upper edge of the carrier plate (in the lift-

ing rail, top) - see Figure below. If the pin peaks out

2 mm from the top, the carrier nut and the follower

nutmustbeexchanged.

Figure 18: The lift nut pin is pro-

vided with a sealing wax

Loading...

Loading...