3

Operating Instructions and Parts Manual 24669

4/18

2018 OEMTOOLS

™

3/8" DRILL

WARNING: Know your drill. DO NOT plug in the

drill until you have read and understand this Instruction

Manual. Learn the tool’s applications and limitations, as

well as the specific potential hazards related to this tool.

Following this rule will reduce the risk of electric shock,

fire, or serious injury.

WARNING: Always wear eye protection. Any power

tool can throw foreign objects into your eyes and cause

permanent eye damage. ALWAYS wear safety goggles

(not glasses) that comply with ANSI safety standard

Z87.1. Everyday glasses have only impact resistant

lenses. They ARE NOT safety glasses.

WARNING: Glasses or goggles not in compliance with

ANSI Z87.1 could cause serious injury when they break.

WARNING: Always use a safety shield, hearing

protection, and dust mask when drilling concrete.

1. DO NOT drill material too small to be securely held.

2. Always keep hands out of the path of the drill bit. Avoid

awkward hand positions where a sudden slip could

cause your hand to move into the path of the drill bit.

3. Secure the workpiece. Use clamps or a vice to hold the

workpiece. It is safer than using your hand and it frees

both hands to operate the tool.

4. Make sure there are no nails or foreign objects in the

part of the workpiece to be drilled.

5. To avoid injury from accidental starting, always remove

the plug from the power source before installing or

removing a drill bit.

6. DO NOT install or use any drill bit that exceeds 7" (17.5

cm) in length or extends more than 6"(15 cm) beyond

the chuck jaws. They can bend or break suddenly.

7. Before starting the operation, jog the drill switch to

make sure the drill bit does not wobble or vibrate.

8. DO NOT use fly cutters or multiple-part hole cutters,

because they can come apart or become unbalanced

during use.

9. Make sure the spindle has come to a complete stop

before touching the chuck or attempting to change the

drill bit.

10. Always make sure the chuck is tight and the drill bit

firmly tightened in the chuck before starting drill.

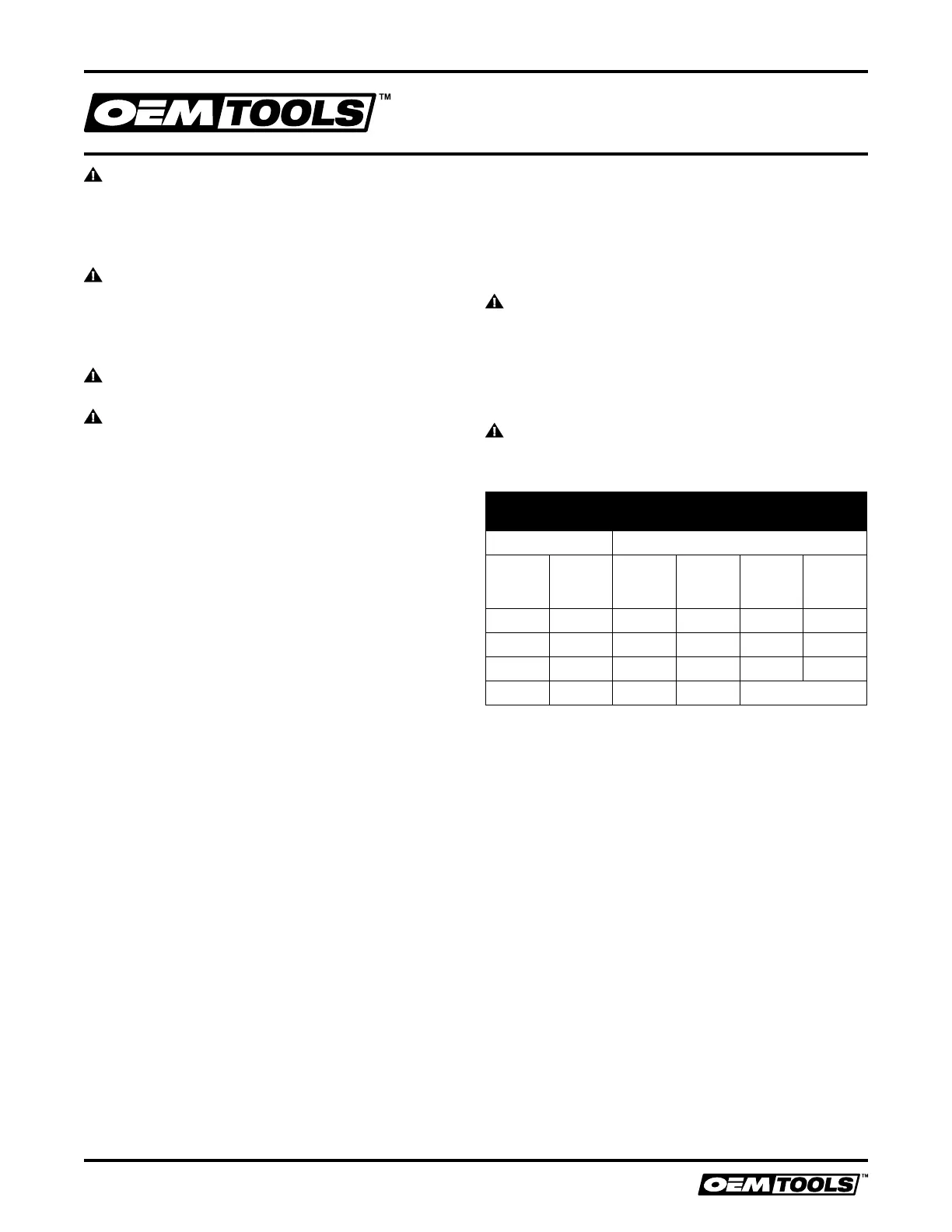

GUIDELINES FOR EXTENSION CORDS

Make sure your extension cord is the proper size.

When using an extension cord, be sure to use one

heavy enough to carry the current the tool will draw.

An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. The table at

right shows the correct size to use according to cord

length and nameplate ampere rating. If in doubt, use

the next heavier gauge. The smaller the gauge number,

the heavier the cord.

Be sure your extension cord is properly wired and in

good condition. Always replace a damaged extension

cord or have it repaired by a qualified electrician before

using it. Protect your extension cord from sharp objects,

excessive heat and damp or wet areas.

Use a separate electrical circuit for your power tools.

This circuit must not be less than 14 gauge wire and

should be protected with either a 15A time delay fuse

or circuit breaker. Before connecting the power tool

to the power source, make sure the switch is in the

OFF position and the power source is the same as

indicated on the nameplate. Running at lower voltage

will damage the motor.

WARNING: Repair or replace damaged or worn

extension cords immediately.

Select the appropriate extension cord gauge and length

using the chart below.

When operating a power tool outdoors, use an outdoor

extension cord marked “W-A” or “W”. These cords are rated

for outdoor use and reduce the risk of electric shock.

WARNING: Keep the extension cord clear of the

working area. Position the cord so it will not get caught

on the workpiece, tools, or any other obstructions while

you are working with the power tool.

Minimum Gauge (AWG) Extension Cords

(120 V use only)

Ampere rating Total length

More

than

Not

more

than

25'

(7.5 m)

50'

(15 m)

100'

(30 m)

150'

(45 m)

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not applicable

IMPORTANT SAFETY INSTRUCTIONS

The warnings, precautions, and instructions discussed

in this manual cannot cover all possible conditions

and situations that may occur. The operator must

understand that common sense and caution are factors

which cannot be built into this product, but must be

supplied by the operator.

DISPOSAL

At the end of the useful life of the OEMTOOLS

™

Drill,

dispose of the components according to all state, federal,

and local regulations.

PURPOSE

The OEMTOOLS

™

3/8" Drill is built with a powerful 4.0

Amp motor to power through the toughest jobs. It is

designed with an easy access forward/reverse lever for

one-hand operation and an ergonomic, rubber mold-

over grip for comfort. It is used for drilling holes, driving

screws, loosening or tightening various materials together

with fasteners and other applications.

Loading...

Loading...