6

Operating Instructions and Parts Manual 24669

4/18

2018 OEMTOOLS

™

3/8" DRILL

When drilling metals, use light oil on the drill bit to keep

it from overheating. The oil will prolong the life of the drill

bit and improve the cutting action. If the bit jams in the

workpiece, or if the drill stalls, release the trigger switch

immediately. Remove the bit from the workpiece and

determine the reason for jamming.

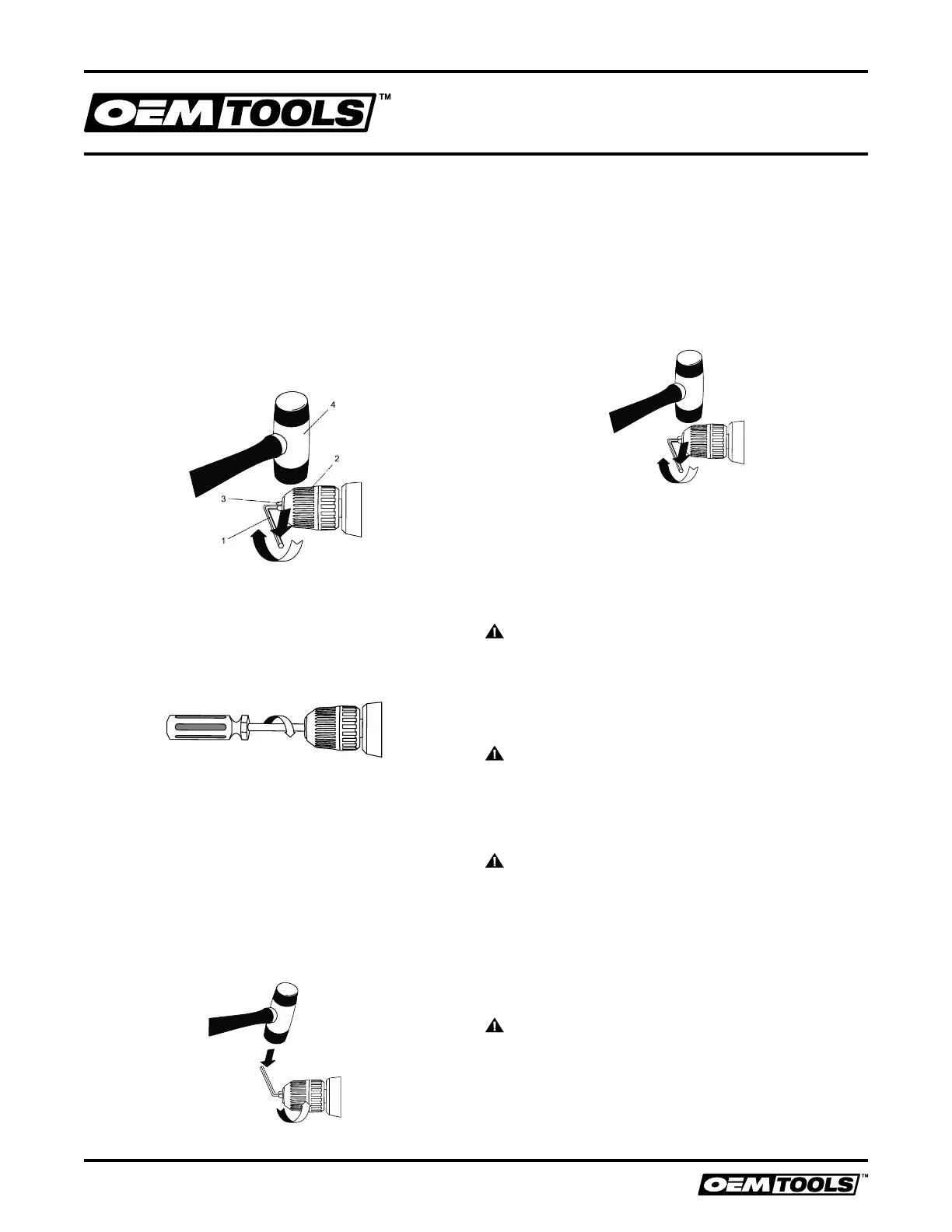

REMOVING THE CHUCK

To remove the chuck:

1. Remove the drill plug from the power source.

2. Insert a 5/16"(8 mm) or larger hex key (1) into the chuck

(2) and tighten the chuck jaws securely (Fig. 7). Make

sure each of the chuck jaws (3) is seated on the flat

surfaces of the hex key.

3. Tap the hex key sharply with a mallet (4) in a clockwise

direction. This action will loosen the screw in the chuck

for easy removal.

4. Open chuck jaws and remove the hex key.

5. Open the chuck jaws as far as possible.

6. Remove the chuck screw using a #2 screwdriver

(Fig. 8)

NOTE: Turn the screw CLOCKWISE to remove it.

This screw has a left-handed thread. Insert the hex

key into the chuck and tighten jaws of chuck securely

(Fig. 9). Tap the hex key sharply with a mallet in a

COUNTERCLOCKWISE direction. This will loosen the

chuck on the spindle. The chuck can now be unscrewed

and removed from the spindle by hand.

Insert the hex key into the chuck and tighten jaws of

chuck securely (Fig. 9). Tap the hex key sharply with a

mallet in a COUNTERCLOCKWISE direction. This will

loosen the chuck on the spindle. The chuck can now be

unscrewed and removed from the spindle by hand.

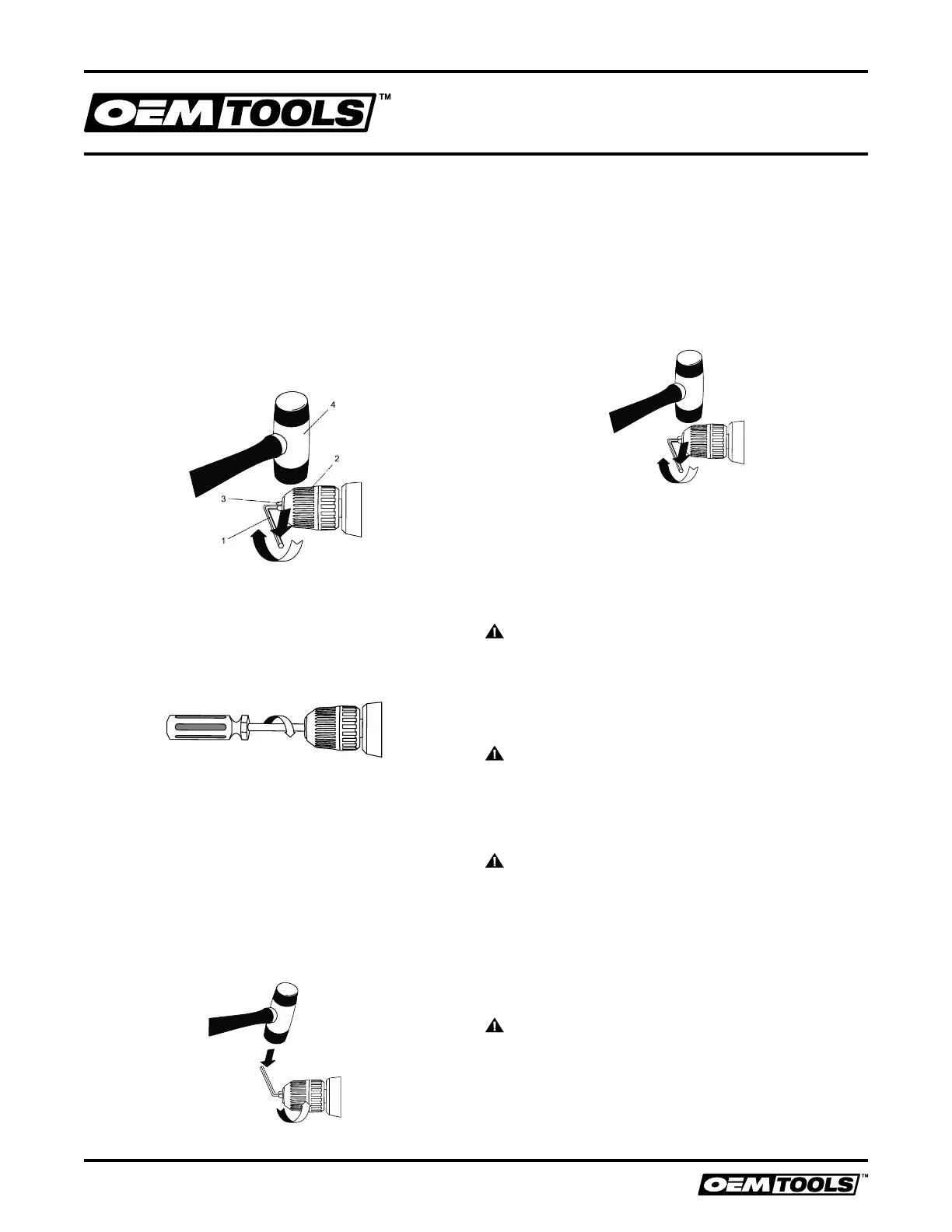

RETIGHTENING A LOOSE CHUCK

After installing a chuck that has previously been removed,

the chuck may become loose on the spindle and develop

a wobble. Also, the chuck screw may become loose,

causing the chuck jaws to bind and prevent them from

closing. To tighten the chuck, follow these steps:

1. Insert the hex key into the chuck and tighten the chuck

securely.

2. Tap the hex key sharply with a mallet in a CLOCKWISE

direction (Fig. 10). This will tighten the chuck on the

spindle.

3. Open the chuck jaws and remove the hex key.

4. Tighten the chuck screw using a #2 screwdriver.

NOTE: Turn the screw COUNTERCLOCKWISE to tighten

it. This screw has a left-handed thread.

MAINTENANCE

WARNING: When servicing, use only identical

replacement parts. The use of any other part may create a

hazard or cause product damage.

DO NOT use solvents when cleaning plastic parts.

Plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use a clean cloth to remove dirt, dust, oil, grease, etc.

WARNING: DO NOT allow brake fluids, gasoline,

petroleum-based products, penetrating oils, etc. to come

into contact with plastic parts. They contain chemicals

that can damage, weaken or destroy plastic.

DO NOT abuse power tools. Abusive practices can

damage the tool and the workpiece.

WARNING: DO NOT attempt to modify tools or create

accessories. Any such alteration or modification is misuse

and could result in a hazardous condition leading to

possible serious injury. It will also void the warranty.

LUBRICATION

All of the bearings in this tool are lubricated with a

sufficient amount of high-grade lubricant for the life of

the unit under normal conditions. Therefore, no further

lubrication is required.

WARNING: When servicing, use only original

equipment replacement parts. The use of any other parts

may create a safety hazard or cause damage to the drill.

Any attempt to repair or replace electrical parts on

this drill may create a safety hazard unless repairs are

performed by a qualified technician. For more information,

call the Toll-free Helpline, at 1-866-458-2472.

Fig. 7

Fig. 8

Fig. 9

Fig. 10

Loading...

Loading...