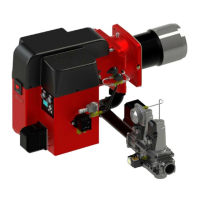

Why does my Oilon Burner keep failing to start?

- EEric WilliamsAug 18, 2025

A start failure in your Oilon Burner can stem from a break in the control loop, preventing the start-up signal from reaching terminal X5-03.1. The safety loop could also be open, or the start-up release loop might be open. Check and repair any breaks or issues found. Additionally, a faulty differential air pressure switch, low gas pressure, or incorrect fuel selector switch position (S2 in position 0) can cause this. Correct these issues by changing the switch, finding the cause of low gas pressure and repairing it, or choosing the correct fuel. High or low return oil pressure can also be the reason, so find the cause and repair it.