30

Maintenance Checklist Cont.:

EVERY 6 MONTHS:

4 Flush out the spill transport pallet (bottom of the pods) with hot water and cleaner/degreasing fluid.

4 Use a clean rag and wipe down electric motors and all painted surface areas.

4 Polish all stainless-steel areas with stainless steel cleaner.

4 Dust the electric motor fan(s).

4 Check tension on Static Discharge Reel.

• If additional tension is needed, apply a wrench to the flats on the mainspring shaft, rotating counterclockwise

until the desired tension isreached.

• If mainspring tension is too high, it may be decreased by depressing tension lock spring on the opposite side of the

reel. DO NOT remove moretension than desired. If too much tension is removed, increase tension as described

above.

4 Inspect the Static Discharge Cable for fraying. Lubrication is not required for the reel.

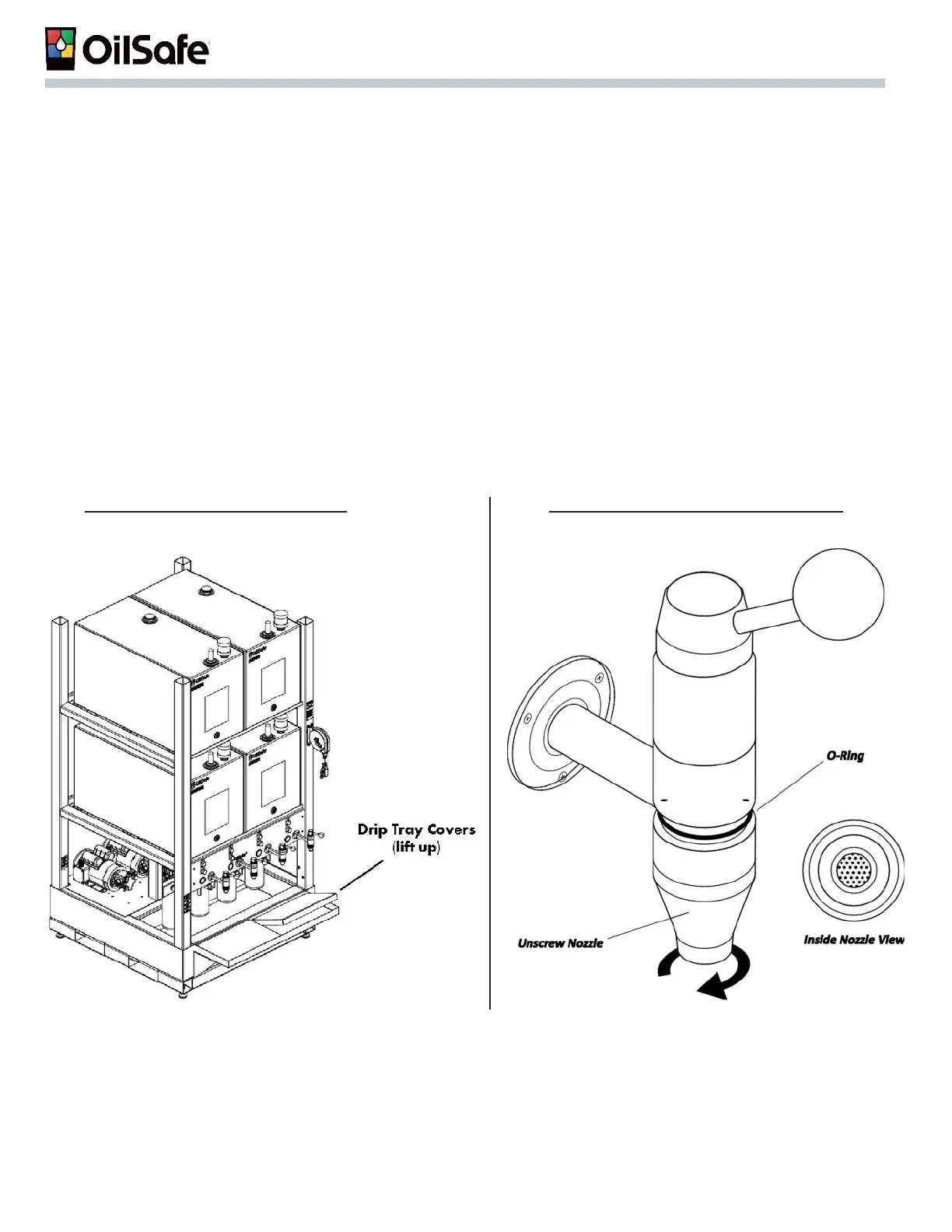

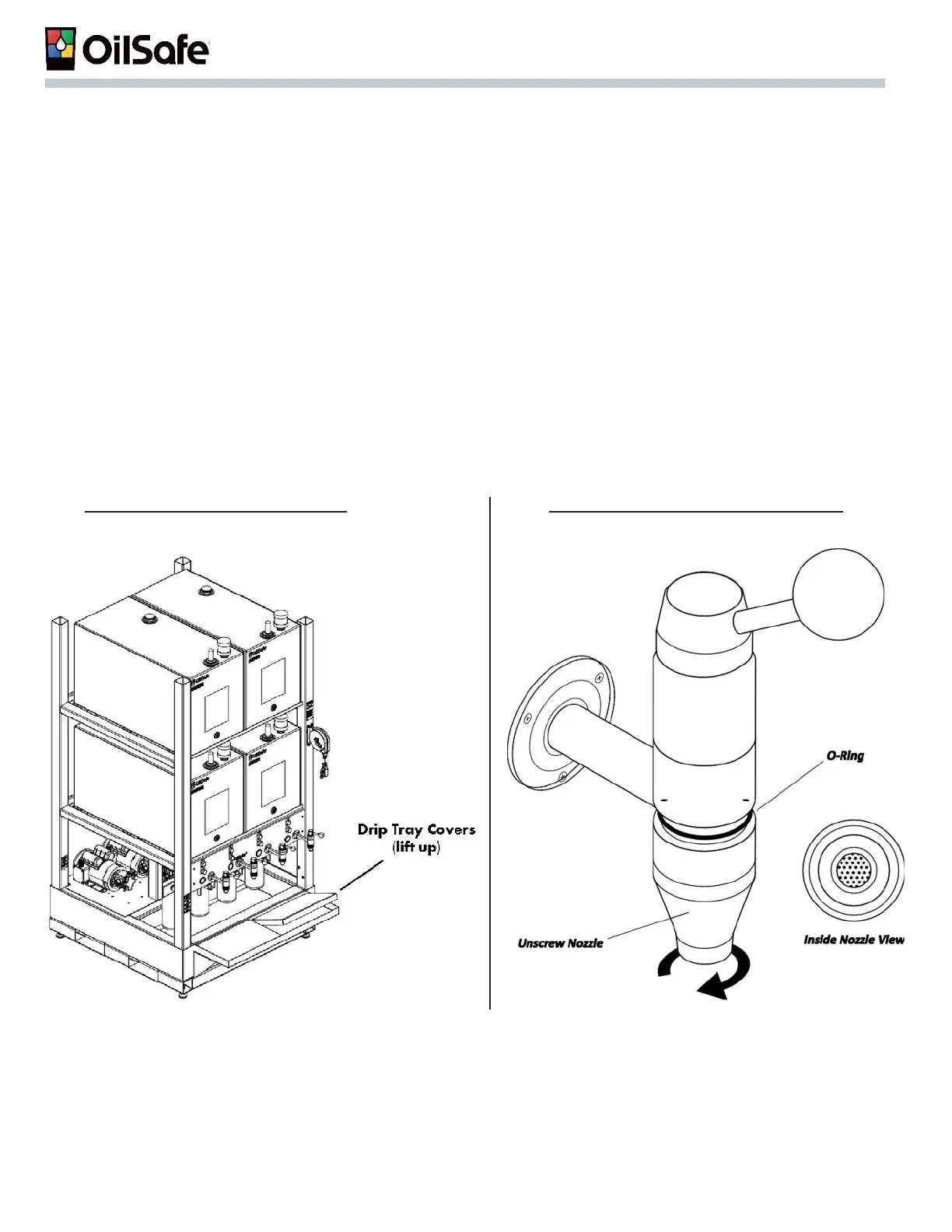

FIGURE 23: Removing Drip Trays FIGURE 24: Removing Faucet Nozzle

Loading...

Loading...