Technical Data for FMA-1600A Mass Flow Meters

0 to 0.5 sccm Full Scale through 0 to 5000 slpm Full Scale

Standard Operating Specications (Contact Omega for available options)

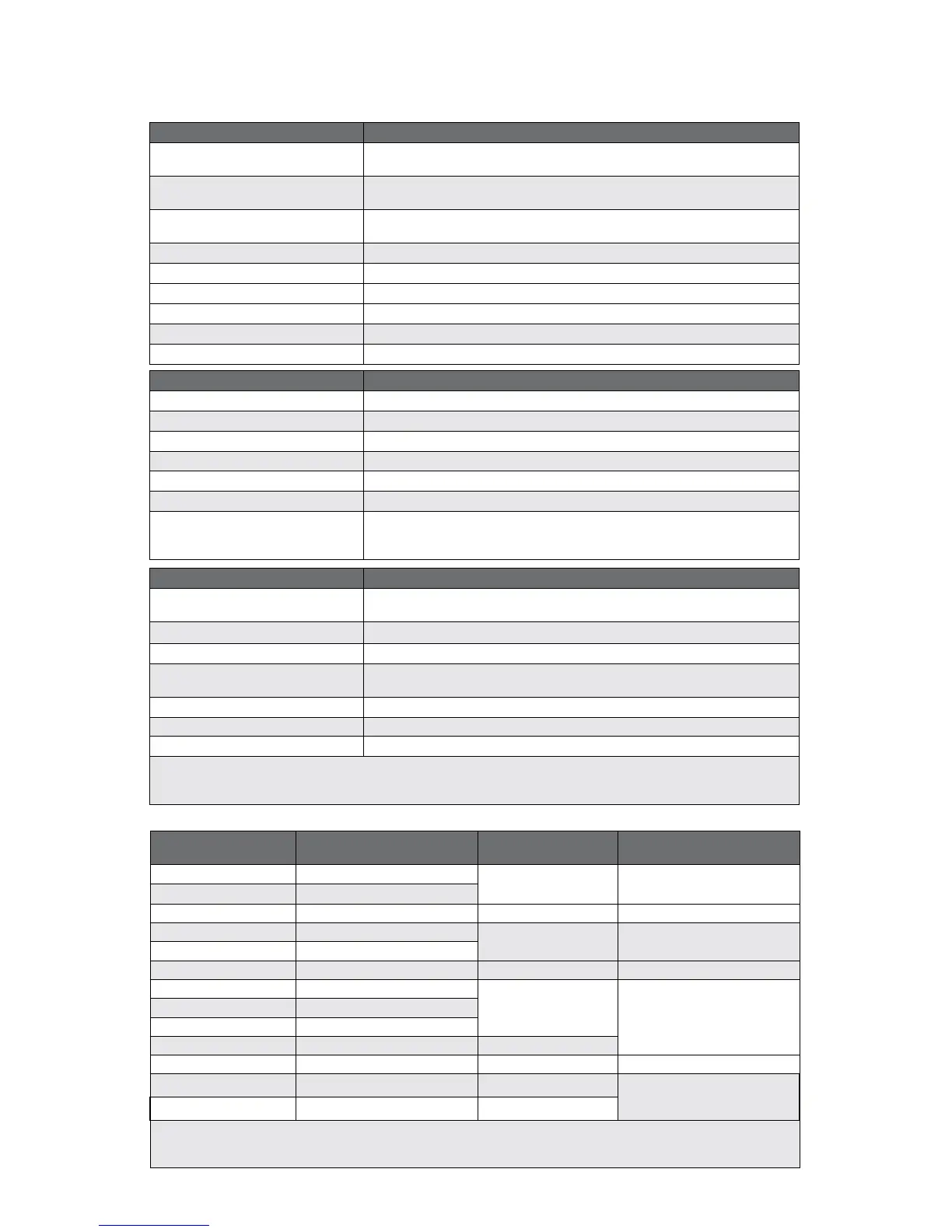

Performance FMA-1600A Mass Flow Meter

Accuracy at calibration conditions

after tare

± (0.8% of Reading + 0.2% of Full Scale)

High Accuracy at calibration conditions

after tare

± (0.4% of Reading + 0.2% of Full Scale)

High Accuracy option not available for units ranged under 5 sccm or over 500 slpm.

Accuracy for Bidirectional Meters

at calibration conditions after tare

± (0.8% of reading + 0.2% of total span from positive full scale to negative full scale)

Repeatability ± 0.2% Full Scale

Zero Shift and Span Shift 0.02% Full Scale / ºCelsius / Atm

Operating Range / Turndown Ratio 0.5% to 100% Full Scale / 200:1 Turndown

Maximum Measurable Flow Rate 128% Full Scale

Typical Response Time 10 ms (Adjustable)

Warm-up Time < 1 Second

Communications / Power FMA-1600A Mass Flow Meter

Monochrome LCD Display with

integrated touchpad

Simultaneously displays Mass Flow, Volumetric Flow, Pressure and Temperature

Digital Output Signal

1

Options RS232 Serial / RS485 Serial

Analog Output Signal

2

Options 0-5 Vdc / 1-5 Vdc / 0-10 Vdc / 4-20 mA

Optional Secondary Analog Output

Signal

2

0-5 Vdc / 1-5 Vdc / 0-10 Vdc / 4-20 mA

Electrical Connection Options 8 Pin Mini-DIN / 15-pin D-sub (DB15)

Supply Voltage 7 to 30 Vdc (15-30 Vdc for 4-20 mA outputs)

Supply Current 0.040 Amp (+ output current on 4-20 mA)

1. The Digital Output Signal communicates Mass Flow, Volumetric Flow, Pressure and Temperature

2. The Analog Output Signal and Optional Secondary Analog Output Signal communicate your choice of Mass

Flow, Volumetric Flow, Pressure or Temperature

Operating Conditions FMA-1600A Mass Flow Meter

Mass Reference Conditions (STP) 25ºC & 14.696 psia (standard — others available on request)

Operating Temperature −10 to +50 ºCelsius

Humidity Range (Non–Condensing) 0 to 100%

Maximum Pressure 145 psig

Mounting Attitude Sensitivity None

Ingress Protection IP40

Wetted Materials

303 & 302 Stainless Steel, FKM Heat Cured Silicone Rubber, Glass Reinforced

Polyphenylene Sulde, Heat Cured Epoxy, Aluminum, Gold, Silicon, Glass.

If your application demands a different material, please contact Omega.

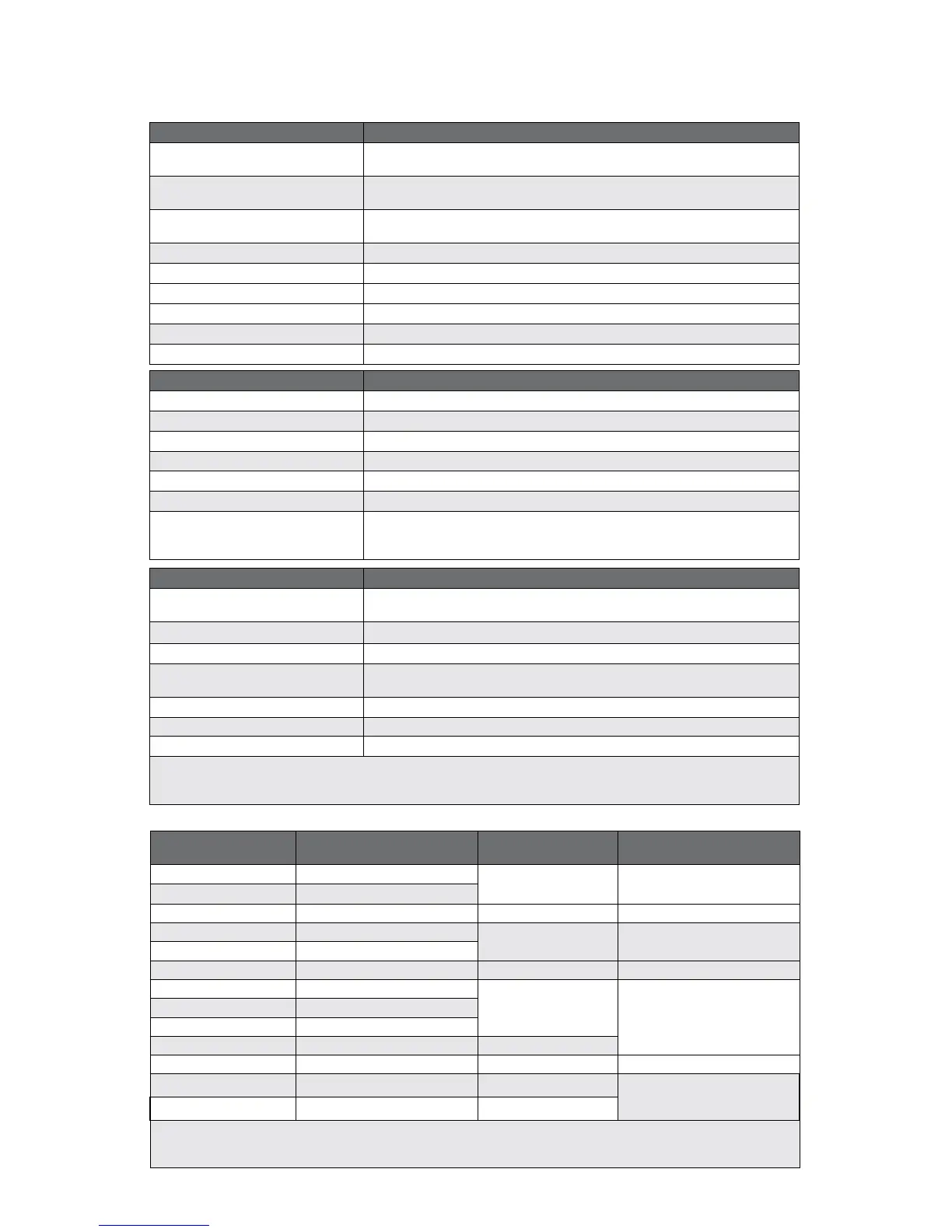

Full Scale Flow Mass

Meter

Pressure Drop at FS Flow

(psid) venting to atmosphere

1

Mechanical

Dimensions

Process Connections

2

0.5 sccm to 1 sccm 1.0

3.9”H x 2.4”W x 1.1”D

M-5 (10-32) Female Thread

2 sccm to 50 sccm 1.0

100 sccm to 20 slpm 1.0 4.1”H x 2.4”W x 1.1”D 1/8” NPT Female

50 slpm 2.0

4.4”H x 4.0”W x 1.6”D 1/4” NPT Female

100 slpm 2.5

250 slpm 2.1 5.0”H x 4.0”W x 1.6”D 1/2” NPT Female

500 slpm 4.0

5.0”H x 4.0”W x 1.6”D

3/4” NPT Female

(A 1-1/4” NPT Female optional

process connection is available

for 2000 slpm meters.)

1000 slpm 6.0

1500 slpm 9.0

2000 slpm 5.0 5.3”H x 5.2”W x 2.9”D

3000 slpm 7.1 5.3”H x 5.2”W x 2.9”D 1-1/4” NPT Female

4000 slpm 4.4 7.6”H x 5.2”W x 2.9”D

2” NPT Female

5000 slpm 3.4 6.3”H x 5.2”W x 3.9”D

1. Lower Pressure Drops Available, please see our FMA-LP1600A mass ow meters.t

2. Compatible with Swagelok® tube, Parker®, face seal, push connect and compression adapter ttings. VCR and SAE

connections upon request.

Range Specic Specications

Loading...

Loading...