4-19

4-2 Wiring

OMNUC G5-series AC Servomotors and Servo Drives User’s Manual (with Built-in EtherCAT Communications)

4

System Design

Terminal Block Wiring Procedure

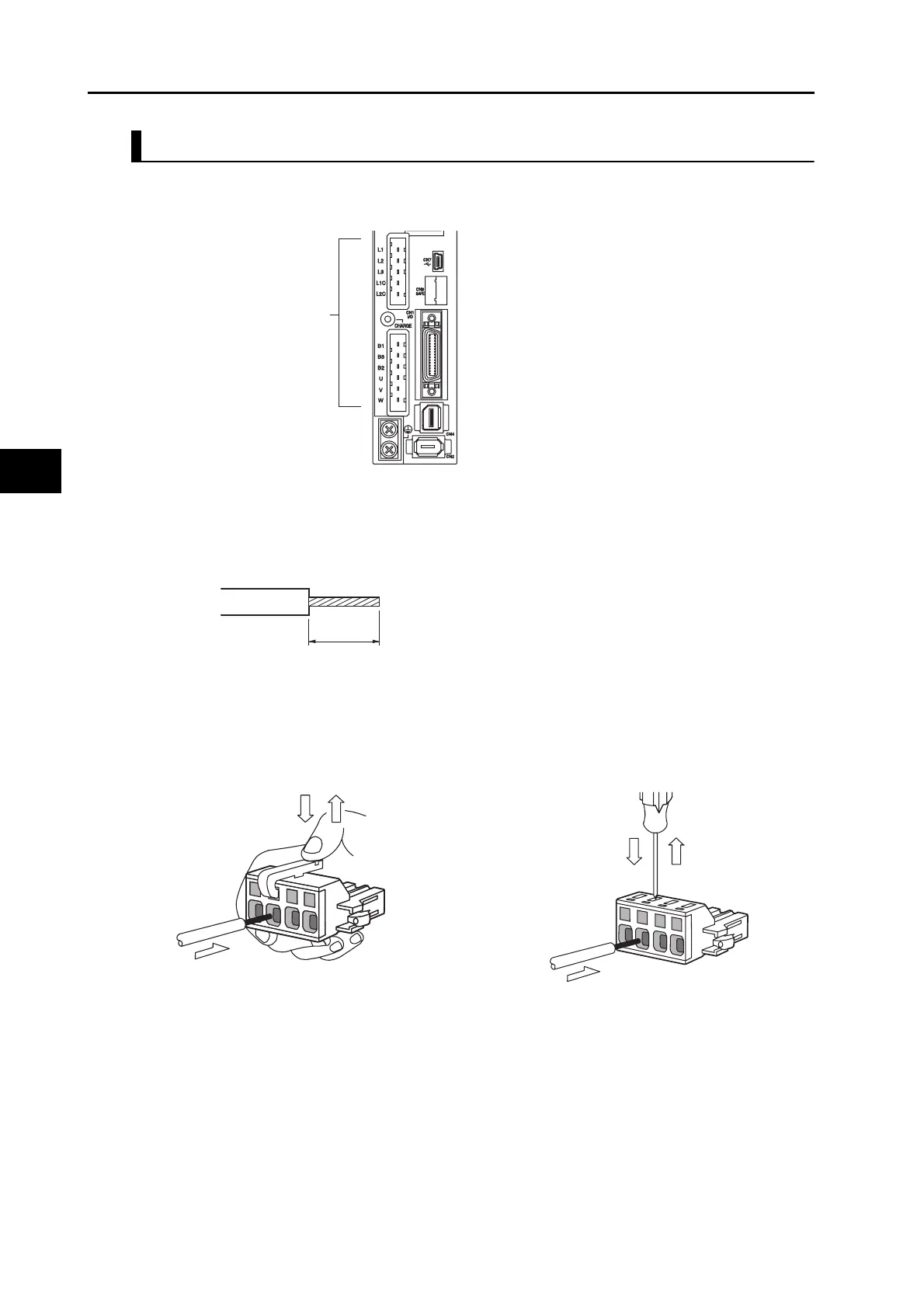

On a Servo Drive with 2.0 kW or less, connector-type terminal blocks are used.

The procedure for wiring these terminal blocks is explained below.

1. Remove the terminal block from the Servo Drive before wiring.

The Servo Drive may be damaged if the wiring is done with the terminal block in place.

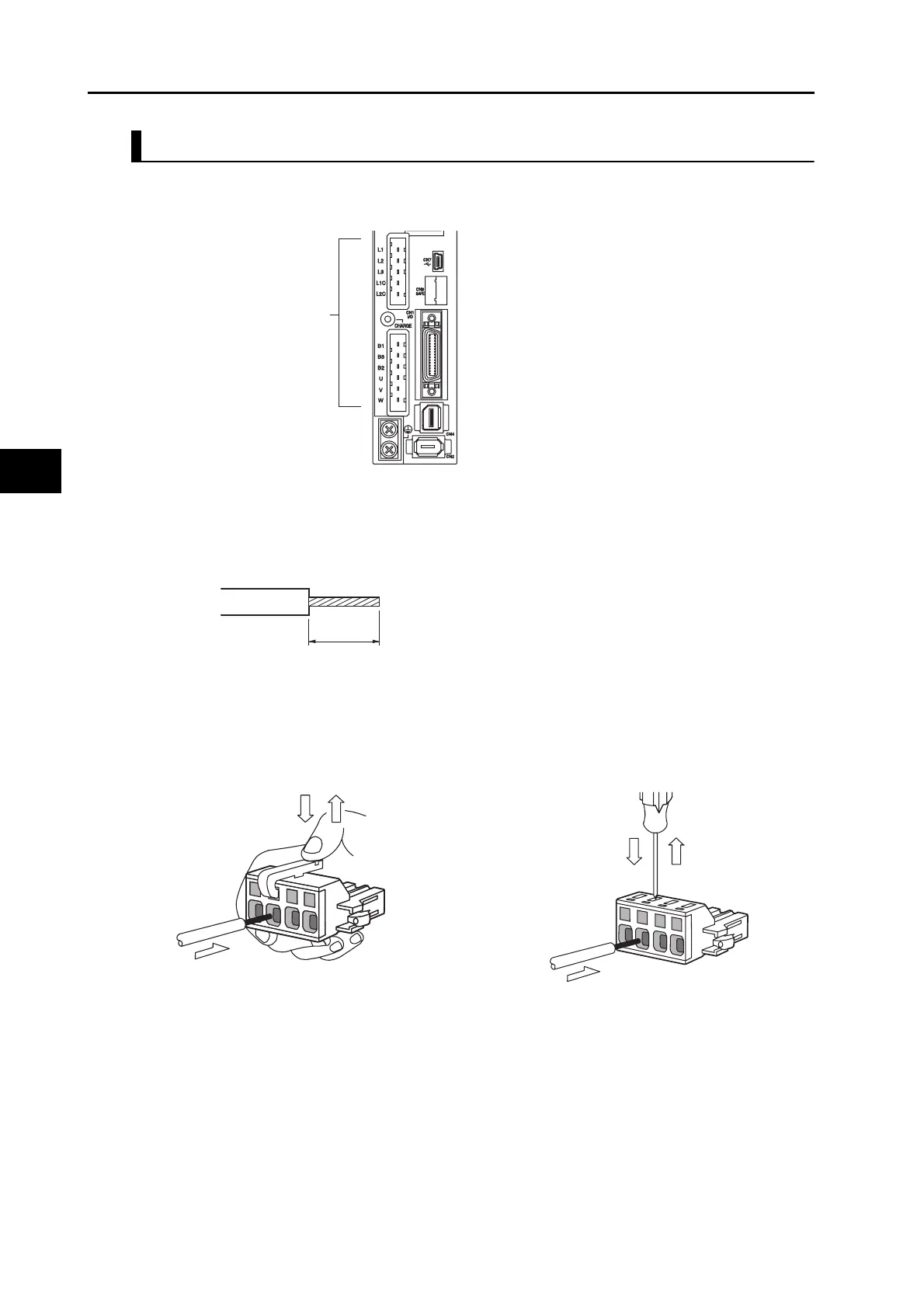

2. Strip off 8 to 9 mm of the covering from the end of each wire.

Refer to Terminal Block Wire Sizes on page 4-16 for applicable wire sizes.

3. Open the wire insertion slots in the terminal block using a tool.

There are 2 ways to open the wire insertion slots, as follows.

Pry the slot open using the lever that comes with the Servo Drive. (Figure A)

Insert a flat-blade screwdriver (end width: 3.0 to 3.5 mm) into the opening for the driver on the

terminal block, and press down firmly to open the slot. (Figure B)

4. With the wire insertion slot held open, insert the end of the wire.

After inserting the wire, let the slot close by releasing the pressure from the lever or the

screwdriver.

5. Mount the terminal block to the Servo Drive.

After all of the terminals have been wired, return the terminal block to its original position on

the Servo Drive.

Connector-type

terminal blocks

(Example of R88D-KN02H-ECT-R)

8 to 9 mm

Figure A

Figure B

Loading...

Loading...