XtraDrive 125

Encoder connector (CN2)

I/O signals (CN1) - input signals

Note: 1. Pin numbers in parentheses () indicate signal grounds.

2. The functions allocated to /S-ON, /P-CON. P-OT, N-OT, /ALM-RST, /P-CL, and /N-CL input signals can be changed by using the

parameters.

3. The voltage input range for speed and torque references is a maximum of ±12 V.

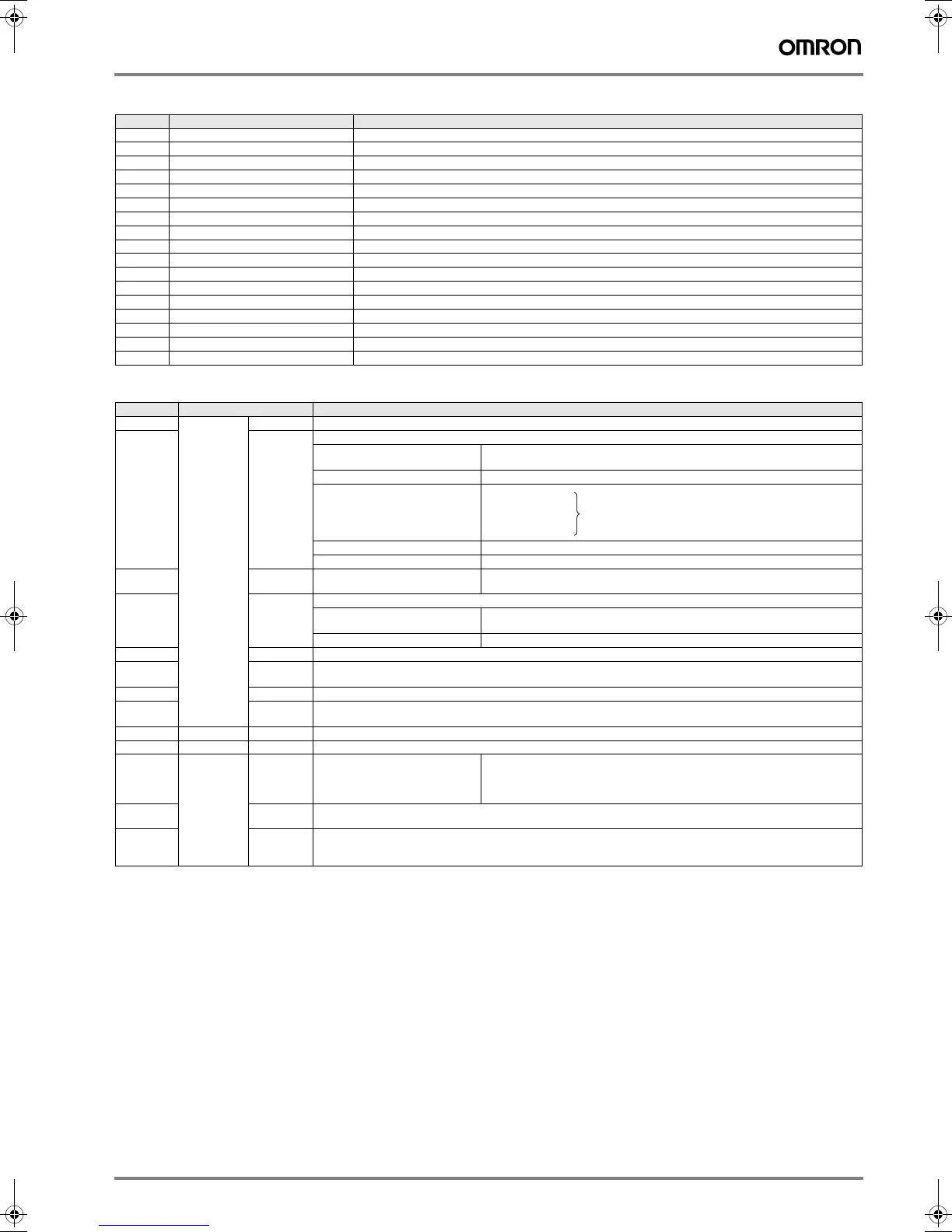

Pin Symbol Function

1, 2, 3 PPG0V Encoder power supply GND

4, 5, 6 PPG5V Encoder power supply +5 V

7- -

8 PS+ Encoder serial signal input

9PS− Encoder serial signal input

10 SePG5V Serial encoder power supply +5 V (Sigma-II)

11 SePG0V Serial encoder power supply GND (Sigma-II)

12 BAT+ Battery + (used only with absolute encoder)

13 BAT- Battery - (used only with absolute encoder)

14 PC+ Encoder + C-phase input

15 PC− Encoder − C-phase input

16 A+ Encoder + A-phase input

17 A− Encoder − A-phase input

18 B+ Encoder + B-phase input

19 B− Encoder − B-phase input

20 - -

Shell FG Cable shield ground

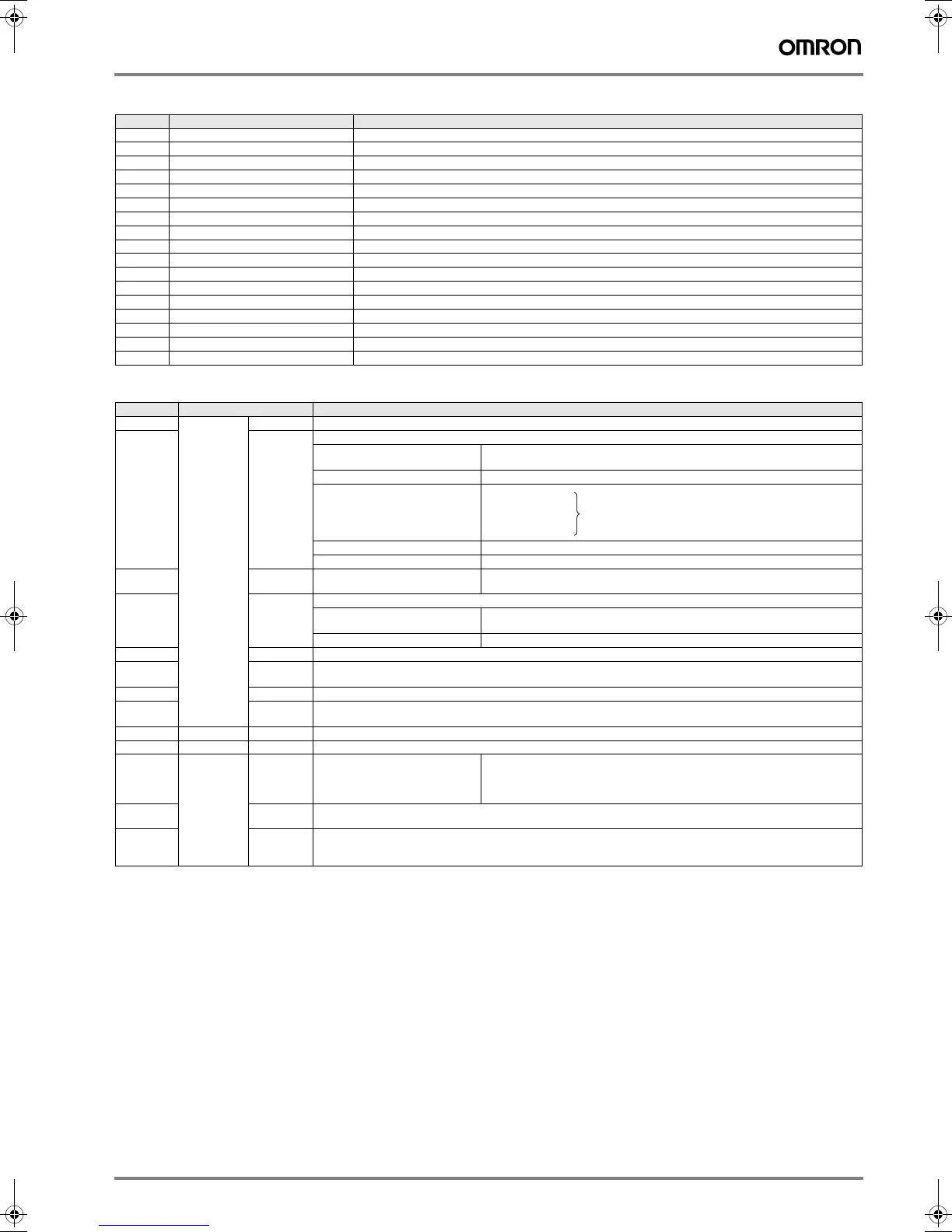

Pin No. Signal Name Function

40 Common /S

-

ON Servo ON: Turns ON the servo motor when the gate block in the inverter is released.

41 /P

-

CON Function selected by parameter.

Proportional control reference Switches the speed control loop from PI (proportional/ integral) to P (proportional)

control when ON.

Direction reference With the internal set speed selected: switch the rotation direction.

Control mode

switching

Zero-clamp reference Speed control with zero-clamp function: referencevspeed is zero when ON.

Reference pulse block Position control with reference pulse stop: stops reference pulse input when ON.

42

43

P

-

OT

N

-

OT

Forward run prohibited

Reverse run prohibited

Overtravel prohibited: stops servo motor when movable part travels beyond the

allowable range of motion.

45

46

/P

-

CL

/N

-

CL

Function selected by parameter.

Forward external torque limit ON

Reverse external torque limit ON

Current limit function enabled when ON.

Internal speed switching With the internal set speed selected: switches the internal speed settings.

44 /ALM

-

RST Alarm reset: releases the servo alarm state.

47 +24VIN Control power supply input for sequence signals: users must provide the +24 V power supply.

Allowable voltage fluctuation range: 11 to 25 V

4 (2) SEN Initial data request signal when using an absolute encoder.

21

22

BAT (+)

BAT (-)

Connecting pin for the absolute encoder backup battery.

Do not connect when a battery is connected to the host controller.

5 (6) Speed V

-

REF Speed reference speed input: ±2 to ±10 V/rated motor speed (input gain can be modified using a parameter.)

9 (10) Torque T

-

REF Torque reference input: ±1 to ±10 V/rated motor torque (input gain can be modified using a parameter.)

7

8

11

12

Position PULS

/PULS

SIGN

/SIGN

Reference pulse input

for line driver only

Input mode is set from the following pulses.

Sign + pulse string

CCW/CW pulse

Two-phase pulse (90° phase differential)

15

14

CLR

/CLR

Positional error pulse clear input: clears the positional error pulse during position control.

3

13

18

PL1

PL2

PL3

+12 V pull-up power is supplied when PULS, SIGN, and CLR reference signals are open-collector outputs

(+12 V power supply is built into the SERVOPACK).

Position speed

Position

torque

Torque speed

Enables control mode switching.

↔

↔

↔

Y203-EN2-02-Katalog.book Seite 125 Mittwoch, 24. Mai 2006 2:22 14

Loading...

Loading...