Do you have a question about the Omron CJ1W- ECT21 and is the answer not in the manual?

Specifies the target personnel for this manual, requiring electrical system knowledge.

Lists the specific products covered by this operation manual.

Explains the layout of pages and the meaning of icons used in the manual.

Details the classification and purpose of special information provided.

Clarifies key terms and their usage within the manual.

Outlines the product warranty terms and limitations of Omron's liability.

Addresses product suitability and buyer responsibilities for specific applications.

States limitations regarding data accuracy, changes, and errors.

Explains the notation used for safety warnings and cautions.

Highlights hazardous situations that could result in severe injury or damage.

Illustrates and explains the meaning of various safety symbols.

Alerts users to potential minor injuries or property damage.

Advises against disassembling, repairing, or dropping the unit.

Provides instructions and precautions for securely mounting the unit.

Gives guidelines for protecting the unit from vibration or impact during transport.

Covers general installation requirements, including grounding and wiring.

Details correct procedures and precautions for electrical wiring.

Discusses considerations for power supply capacity and surge current.

Outlines the correct sequence and precautions for powering up the PLC.

Emphasizes pre-operation checks for user programs and settings.

Details precautions for powering down the PLC and its units.

Covers operational considerations for changing modes or settings.

Provides guidelines for EtherCAT network setup and potential issues.

Details precautions and steps for replacing faulty units.

Gives guidance on proper disposal of the product according to ordinances.

Details correct practices for storing, mounting, and wiring the unit.

Warns against disconnecting EtherCAT cables during operation.

Highlights the impact of environmental conditions on system longevity.

Details compliance with European Union directives and EMC standards.

Outlines compliance with North American safety standards.

Specifies compliance with maritime industry standards.

Details compliance with Korean safety standards.

Describes how to find the unit version on the product nameplate.

Details methods to check unit versions using support software.

Explains compatibility between unit versions and CX-Programmer versions.

Explains EtherCAT technology, its high performance, and communication mechanisms.

Highlights key features of the EtherCAT Slave Unit, including data exchange.

Illustrates a typical system configuration with components and their roles.

Lists the general, functional, and performance specifications of the unit.

Outlines the basic hardware and software setting procedures for the unit.

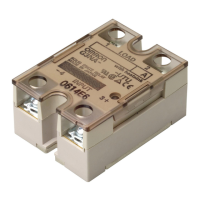

Identifies and describes the unit's front panel components and indicators.

Provides instructions for mounting the unit to a CJ-series PLC system.

Details installation standards and precautions for EtherCAT network wiring.

Describes the CIO and DM area words allocated to the unit.

Details the CIO area word allocations for unit status and control.

Explains the DM area allocations for I/O communication settings.

Covers configuring I/O areas using the CX-Programmer Edit Parameters Dialog Box.

Explains the structure of the CoE protocol for EtherCAT.

Details the role of ESI files in EtherCAT network configuration.

Describes the EtherCAT Slave Unit's communication state transitions.

Explains Process Data Objects (PDOs) for cyclic data transfer.

Details Service Data Objects (SDOs) for message-based communication.

Covers I/O response time and SDO message response time calculations.

Explains how errors are notified and provides methods for checking them.

Guides users on diagnosing errors using the unit's indicators.

Details how to access and interpret the unit's error log.

Explains the reporting of emergency messages for detected errors.

Covers troubleshooting procedures based on AL status codes.

Outlines routine cleaning and inspection procedures for regular maintenance.

Details the precautions and steps for replacing a faulty EtherCAT Slave Unit.

Shows a practical example of setting up EtherCAT Slave Unit communications.

Demonstrates a programming example to verify I/O process data validity.

Explains process data exchange behavior when the unit enters PROGRAM mode.

Lists and describes the CoE objects implemented by the EtherCAT Slave Unit.

Guides on creating I/O tables using CX-Programmer or Programming Console.

Details FINS commands supported by the EtherCAT Slave Unit.

Shows compatibility between unit versions and CX-Programmer versions.

| Brand | Omron |

|---|---|

| Model | CJ1W- ECT21 |

| Category | Computer Hardware |

| Language | English |