BATTERIES

BATTERY

CARE

To increase battery life, the operator can perform a

numberof routine checks and some preventive main-

tenance.

1.

Keep the battery case clean and dry.

2.

Make sure the battery cable connections are

clean and tight. Use a terminal puller when re-

moving cables for any reason.

3. Coat the battery terminals with a mineral grease

or petroleum jelly to reduce corrosion and oxida-

tion.

4.

Identify each battery cable to be positive or nega-

tive before making any connection. Always

con-

nect the ground (negative) cable last.

5. Maintain the electrolyte level by adding water

(drinking quality or better) as needed for filling to

split level marker. (The water ingredient of the

electrolyte evaporates, but the sulphuric acid

ingredient remains. Therefore, add water, not

electrolyte).

6. Avoid overcharging when recharging. Stop the

boost charge when the specifc gravity is 1.260

and the electrolyte is 80°F (26.7

0

C).

BATTERIES

AND

BATTERY

CABLES

In order for the electric generating set to crank

effi-

ciently under various operating conditions, the bat-

tery and battery cables must be correctly chosen and

installed.

Before selecting a battery, be sure the

installation area is compatible and properly de-

signed.

The compartment for the battery must

provide:

1.

Rigid mounting support.

2.

A location where accidental acid spills or leaks

won't damage set, battery cables, etc.

3. Provide a minimum of 2 square inches at top and

2 square inches at bottom of battery for ventila-

tion purposes.

4.

Battery cable entry points should be sealed

(vapor tight) if they enter or pass through living

area.

CAUTION

WARNING

Mount the battery in a separate compartment

from the set or any spark-producing device to

simultaneously.

Never disconnect the battery with either

engine running and never crank both engines

BATTERY

CABLES

For reliable starting, voltage drop from the battery

terminals to the exciter cranking windings ofthe

gen-

erator should not exceed 0.12 volts per 100 amperes

of break-away current while cranking. Disconnect

lead to fuel solenoid during test to prevent set from

starting.

Measure voltage at battery terminals and at

start solenoid terminal while cranking. Connect the

battery negative to ground with the same size cable

as used for battery positive.

Be sure the frame connection (major frame member if

possible) is sufficient to minimize resistance. Try to

avoid a connection at a weld or mechanical joint.

For short distances, one negative battery cable can

be used between set and battery rather then separate

cables to chassis ground.

The 12.0RDJC draws 475 amperes of cranking current.

The break-away current is approximately 715 amperes.

The charging current varies from 2-5 amperes depend-

ing on battery condition (state of charge).

For additional information on installation contact

your Onan Service Representative.

Onan recommends using a separate battery for operation of the

generator in addition to the regular vehicle starting battery.

^ARNIN^^

Do not

disconnect battery cables from bat-

tery while generator set is cranking or

run-

ning;

sparks may cause an explosion.

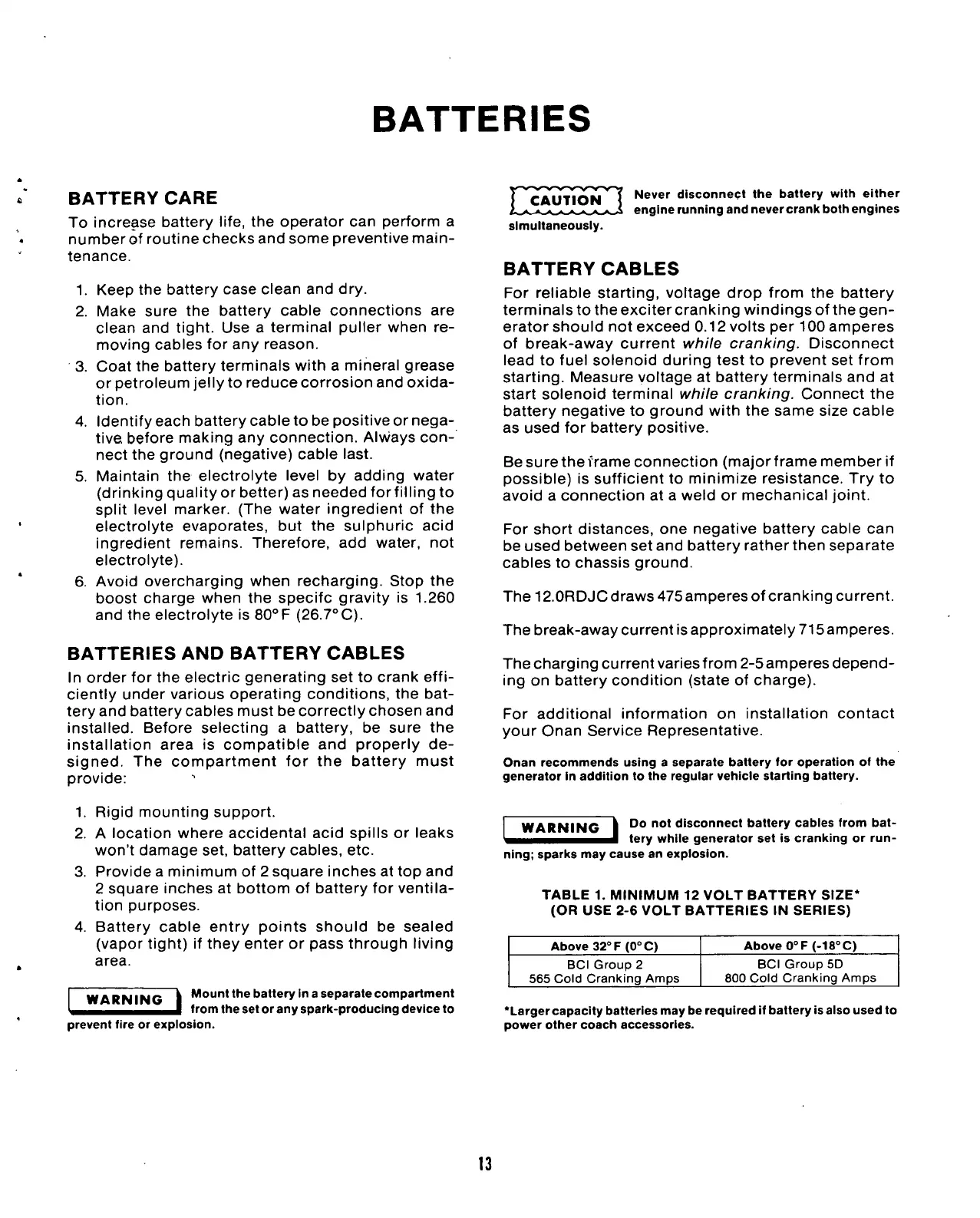

TABLE 1. MINIMUM 12 VOLT BATTERY SIZE*

(OR USE 2-6 VOLT BATTERIES IN SERIES)

Above 32°F(0

o

C)

Above 0°F (-18° C)

BCI Group 2

565 Cold Cranking Amps

BCI Group 5D

800 Cold Cranking Amps

prevent fire or explosion.

'Larger capacity batteries may be required if battery is also used to

power other coach accessories.

13

Loading...

Loading...