VENTILATION

AND

ACOUSTICS

The most important factors of ventilation for an air-

cooled JW electric generating set are sufficient in-

coming'cooling airand exhausting heated air. Before

considering the installation problems, knowledge of

how an Onan unit cools itself is needed. See Figure 4.

WARNING

Never use discharged cooling air for heating

since it can contain poisonous gases.

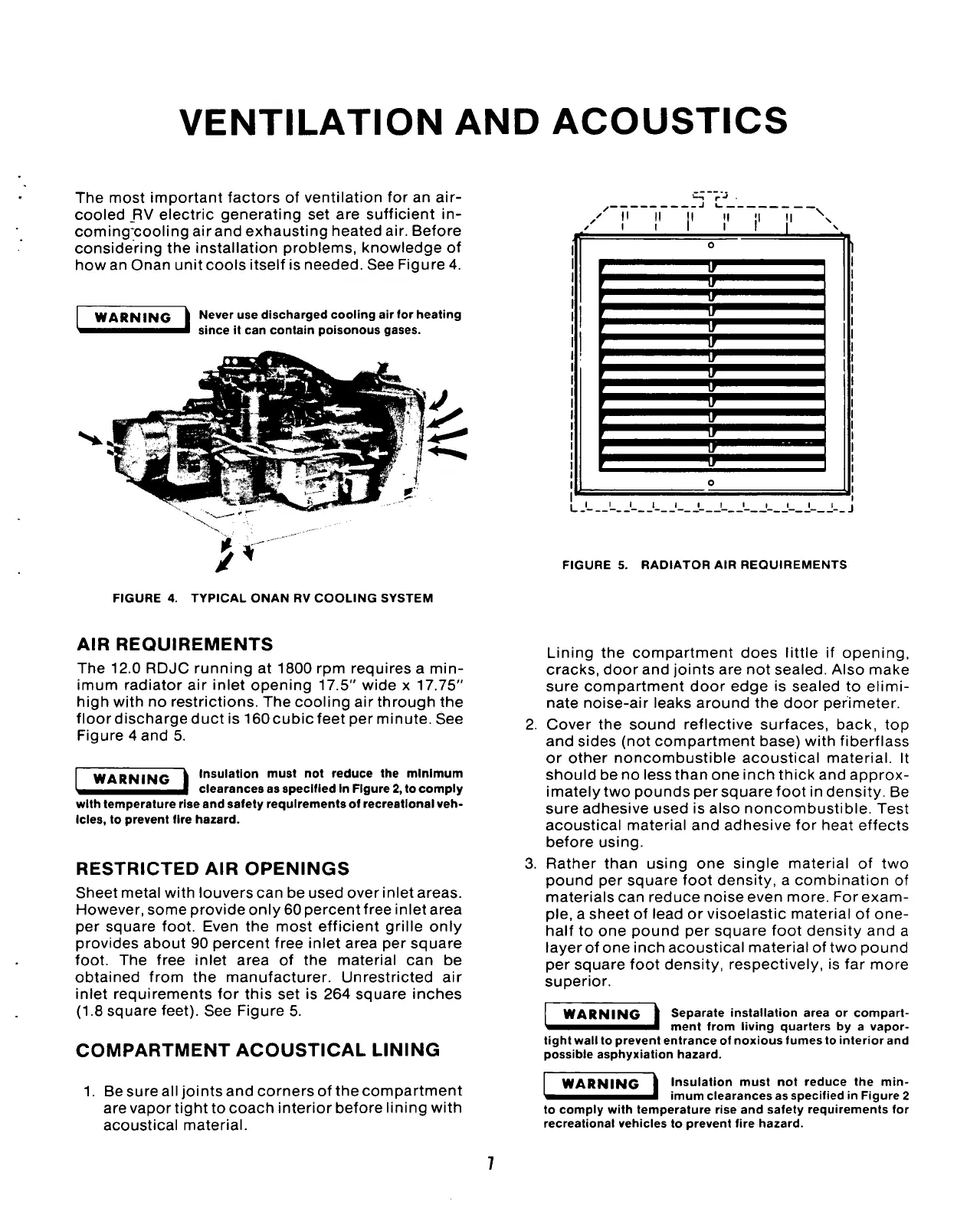

FIGURE 5. RADIATOR AIR REQUIREMENTS

FIGURE 4. TYPICAL ONAN RV COOLING SYSTEM

AIR

REQUIREMENTS

The 12.0 RDJC running at 1800 rpm requires a

min-

imum radiator air inlet opening 17.5" wide x 17.75"

high with no restrictions. The cooling air through the

floordischargeductis 160cubicfeet perminute. See

Figure 4 and 5.

WARNING

Insulation must not reduce the minimum

clearances as specified In Figure

2,

to comply

with temperature rise and safety requirements of recreational

veh-

icles,

to prevent fire hazard.

RESTRICTED

AIR

OPENINGS

Sheet metal with louvers can be used over inlet areas.

However, some provide only 60 percent free inlet area

per square foot. Even the most efficient grille only

provides about 90 percent free inlet area per square

foot. The free inlet area of the material can be

obtained from the manufacturer. Unrestricted air

inlet requirements for this set is 264 square inches

(1.8 square feet). See Figure 5.

COMPARTMENT

ACOUSTICAL

LINING

1.

Be sure all joints and corners of the compartment

are vapor tight to coach interior before lining with

acoustical material.

Lining the compartment does little if opening,

cracks, door and joints are not sealed. Also make

sure compartment door edge is sealed to elimi-

nate noise-air leaks around the door perimeter.

2.

Cover the sound reflective surfaces, back, top

and sides (not compartment base) with fiberflass

or other noncombustible acoustical material. It

should be no less than one inch thick and approx-

imately two pounds persquarefoot in density. Be

sure adhesive used is also noncombustible. Test

acoustical material and adhesive for heat effects

before using.

3. Rather than using one single material of two

pound per square foot density, a combination of

materials can reduce noise even more. For exam-

ple,

a sheet of lead or visoelastic material of one-

half to one pound per square foot density and a

layer of one inch acoustical material of two pound

per square foot density, respectively, is far more

superior.

WARNING

Separate installation area or compart-

ment from living quarters by a vapor-

tight wall to prevent entrance of noxious fumes to interior and

possible asphyxiation hazard.

WARNING

Insulation must not reduce the

min-

imum clearances as specified in Figure 2

to comply with temperature rise and safety requirements for

recreational vehicles to prevent fire hazard.

Loading...

Loading...