Priming Fuel System: Verify that

all

connections

in

the fuel system are secure and no leaks exist. Proceed

with priming

as

follows:

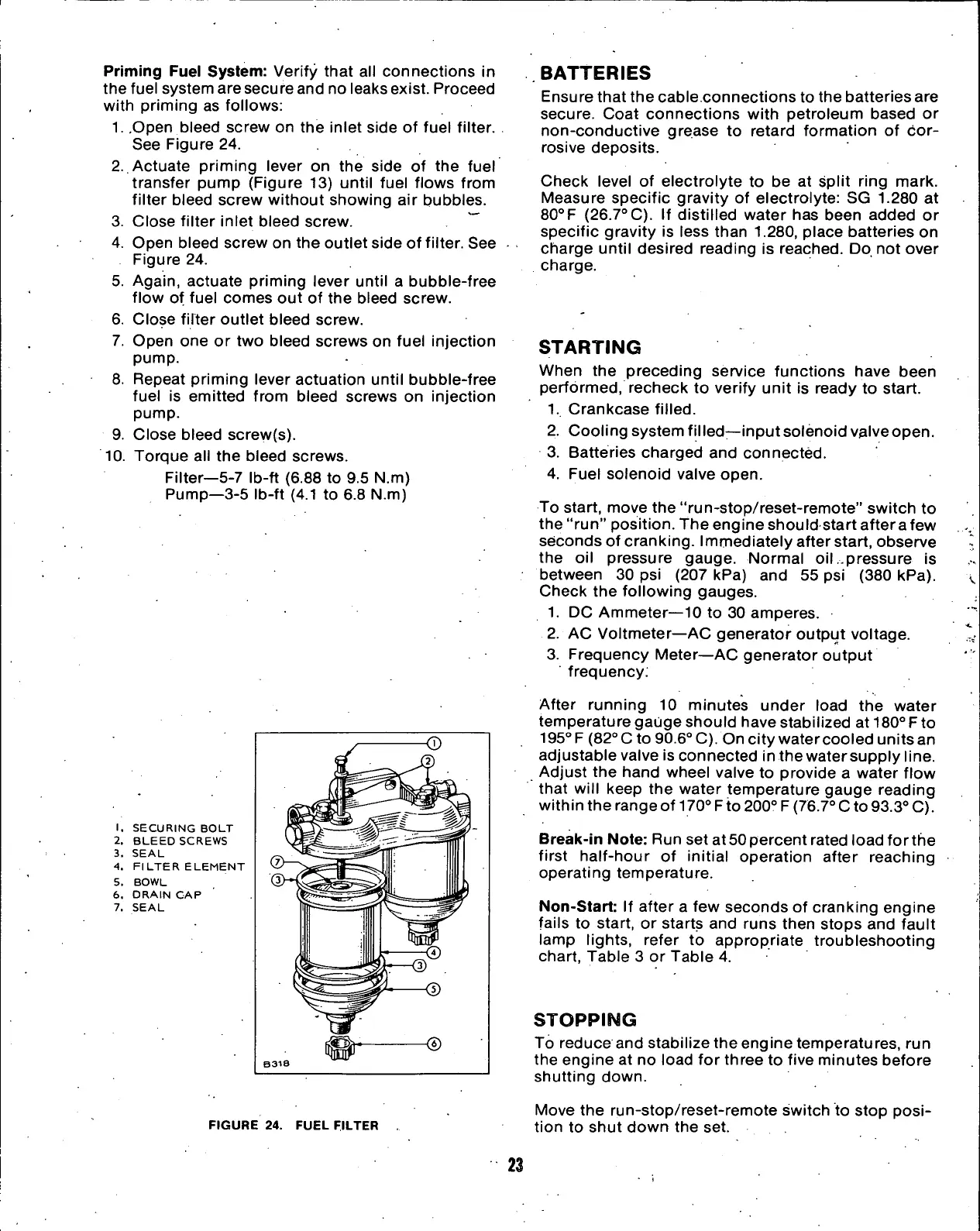

1.

.Open bleed screw

on the

inlet side

of

fuel filter.

See Figure

24.

2.

Actuate priming lever

on the

side

of the

fuel

transfer pump (Figure

13)

until fuel flows from

filter bleed screw without showing

air

bubbles.

3. Close filter inlet bleed screw.

"

4.

Open bleed screw

on

the outlet side

of

filter. See

Figure

24.

5. Again, actuate priming lever until

a

bubble-free

flow

of

fuel comes

out of the

bleed screw.

6. Close filter outlet bleed screw.

7. Open

one or two

bleed screws

on

fuel injection

pump.

8. Repeat priming lever actuation until bubble-free

fuel

is

emitted from bleed screws

on

injection

pump.

9. Close bleed screw(s).

10.

Torque

all the

bleed screws.

Filter—5-7 Ib-ft (6.88

to 9.5 N.m)

Pump—3-5 Ib-ft (4.1

to 6.8 N.m)

1.

SECURING BOLT

2.

BLEED SCREWS

3. SEAL

4.

FILTER ELEMENT

5. BOWL

6. DRAIN

CAP

7. SEAL

FIGURE 24. FUEL FILTER

BATTERIES

Ensure that the cable.connections

to

the batteries are

secure. Coat connections with petroleum based

or

non-conductive grease

to

retard formation

of

cor-

rosive deposits.

Check level

of

electrolyte

to be at

split ring mark.

Measure specific gravity

of

electrolyte:

SG 1.280 at

80°F (26.7°C).

If

distilled water

has

been added

or

specific gravity

is

less than

1.280,

place batteries

on

charge until desired reading

is

reached. Do,

not

over

charge.

STARTING

When

the

preceding service functions have been

performed,

recheck

to

verify unit

is

ready

to

start.

1.

Crankcase filled.

2.

Cooling system filled—input solenoid valve open.

3. Batteries charged

and

connected.

4.

Fuel solenoid valve open.

To start, move the "run-stop/reset-remote" switch

to

the "run" position. The engine should start after a few

seconds

of

cranking. Immediately after start, observe

the

oil

pressure gauge. Normal

oil

.pressure

is

between

30 psi

(207 kPa)

and 55 psi

(380 kPa).

Check

the

following gauges.

1.

DC

Ammeter—10

to 30

amperes.

2.

AC

Voltmeter—AC generator output voltage.

3. Frequency Meter—AC generator output

frequency.

After running

10

minutes under load

the

water

temperature gauge should have stabilized

at

180° Fto

195°

F

(82° C

to

90.6° C). On city watercooled units an

adjustable valve

is

connected in the water supply line.

Adjust

the

hand wheel valve

to

provide

a

water flow

that will keep

the

water temperature gauge reading

within the range

of

170°

F

to 200° F (76.7° C to 93.3° C).

Break-in Note: Run set at 50 percent rated load forthe

first half-hour

of

initial operation after reaching

operating temperature.

Non-Start:

If

after

a few

seconds

of

cranking engine

fails

to

start,

or

starts

and

runs then stops and fault

lamp lights, refer

to

appropriate troubleshooting

chart, Table

3 or

Table

4.

STOPPING

To reduce and stabilize the engine temperatures,

run

the engine

at no

load

for

three

to

five minutes before

shutting down.

Move

the

run-stop/reset-remote switch

to

stop

posi-

tion

to

shut down

the set.

23

Loading...

Loading...