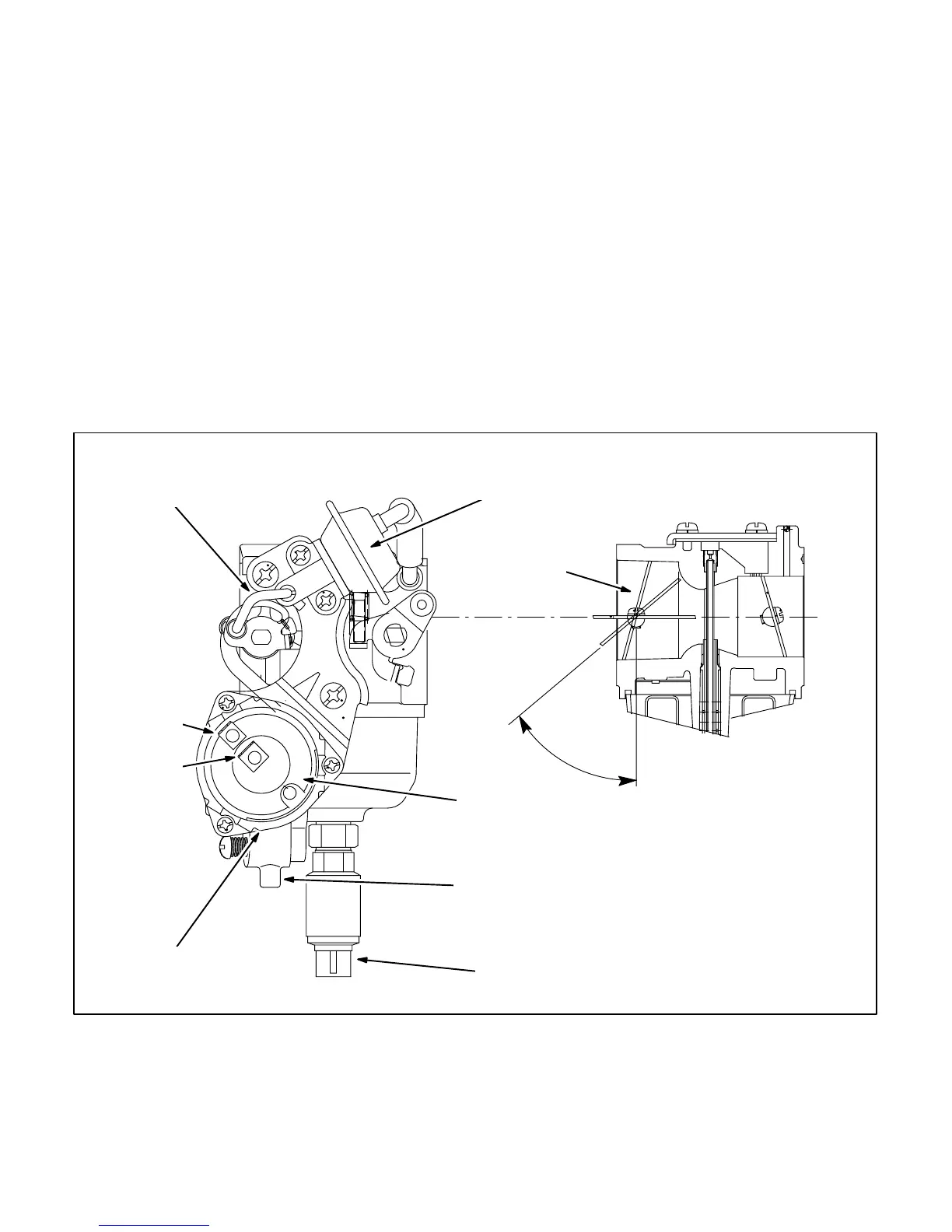

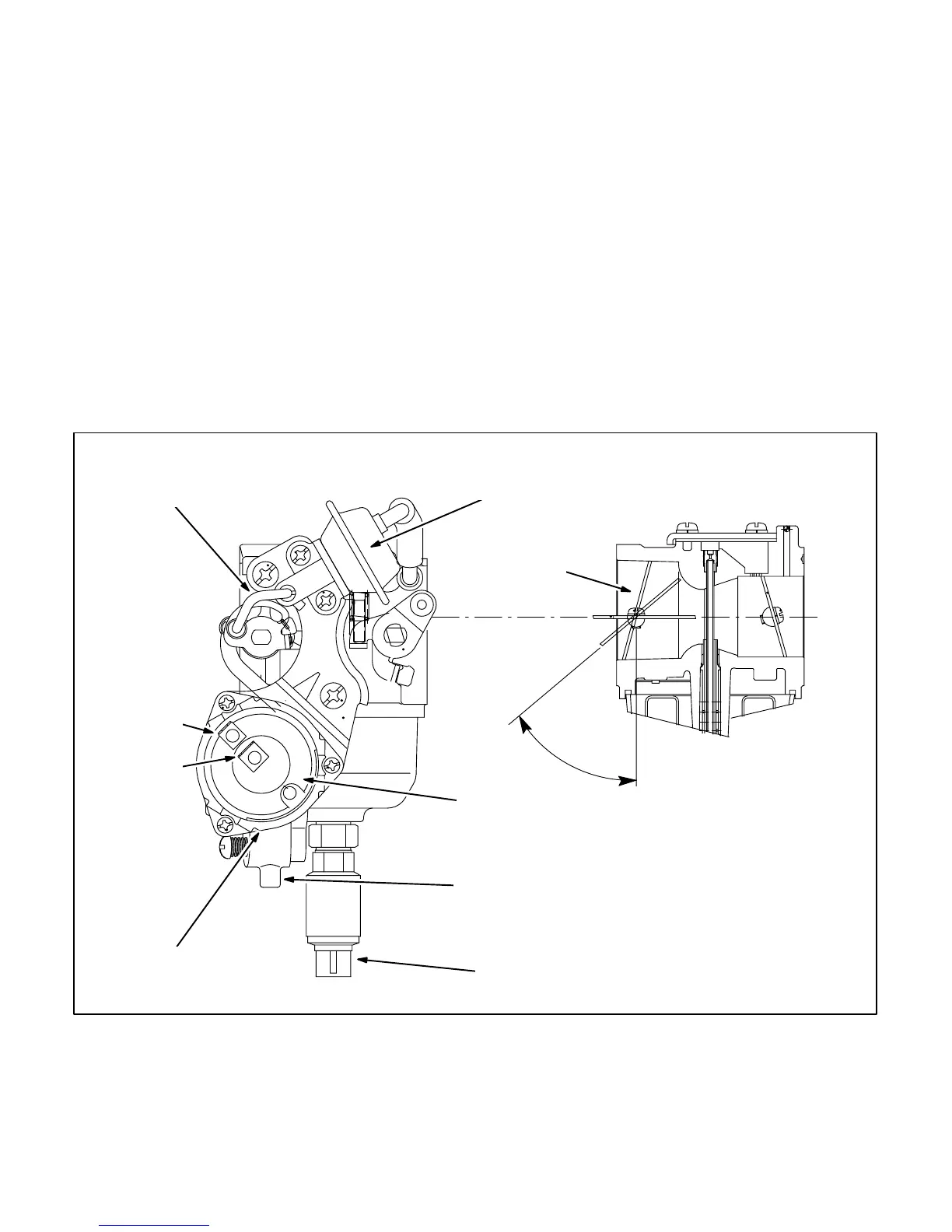

8-10

Carburetor

The carburetor (Figure 8-10) is not likely to cause

problems and should be replaced only after all other

problems have been eliminated (see Section 11.

Troubleshooting). The carburetor fuel mixture ad-

justments are sealed at the factory. See Page 8-20

to connect the throttle link and to adjust the idle

(throttle) stop screw.

Automatic Choke

The automatic choke is operated by a bi-metal/heat-

er assembly and a vacuum breaker assembly (Fig-

ure 8-10). Conduct the following checks and adjust-

ments before replacing a carburetor/choke

assembly:

1. Apply 12 VDC across the heater terminals. The

choke should open fully in 2 to 3 minutes.

2. Check the heater alignment marks and realign

if out of alignment. The choke should be closed

at temperatures below 70° F (21° C). It may be

partly open above 70° F (21° C), but should

close almost completely when vibrated (engine

cranked).

3. The vacuum breaker diaphragm must not leak

under a vacuum of 30 inches Hg (100 kPa). It

should not take a vacuum greater than

2.4 inches Hg (8 kPa) to open the choke fully.

At a vacuum of 1 inch Hg (3.2 kPa) the choke

plate should be at the angle shown (Fig-

ure 8-10). If necessary, bend the link at the

point shown, using two pliers.

47°–53° @

–3.2 kPa & 25° C

FUEL CUTOFF

SOLENOID E4

CHOKE BI-METAL/

HEATER ASSEMBLY

HEATER

ALIGNMENT

MARKS

B+

B–

CHOKE

PLATE

VACUUM BREAKER

ASSEMBLY

FLOAT BOWL

DRAIN

BREAKER

LINK

FIGURE 8-10. CARBURETOR / CHOKE ASSEMBLY

Loading...

Loading...