Thoroughly clean the valve seat counterbore and

remove any burrs from the edges. If the counterbore

is damaged, machine for an oversize seat. Oversize

seats are available in .002”,

.005”,

-010“ and .025”.

Otherwise, install new standard-size seat inserts.

Drive the new valve seat inserts into place. Each seat

must rest solidly on the bottom of the counterbore at

all points. To ease installation, heat the cylinder head

in an oven at 325°F for about 1/2 hour and cool the

valve seats in dry ice.

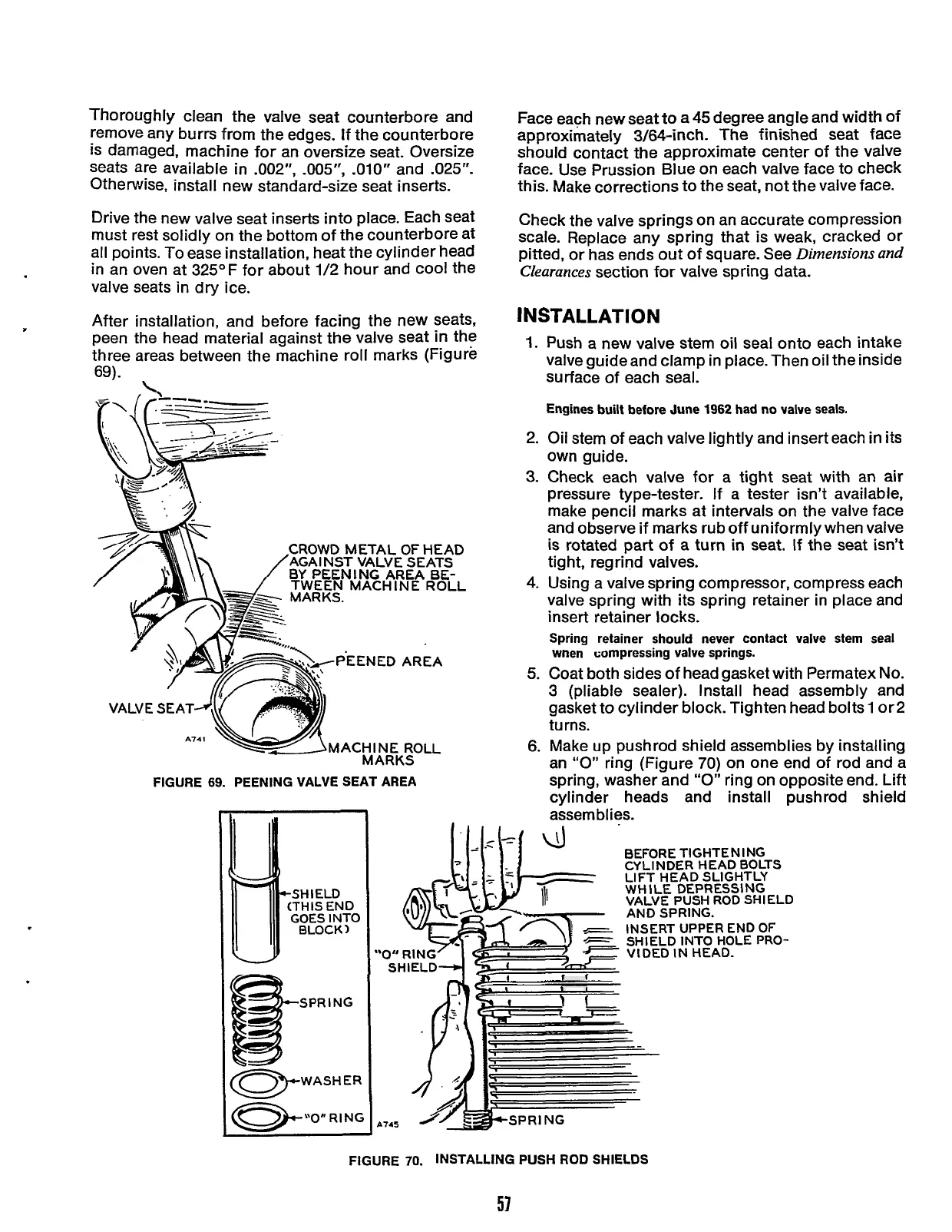

After installation, and before facing the new seats,

peen the head material against the valve seat in the

three areas between the machine roll marks (Figure

69).

CROWD METAL

OF

HEAD

AGAl

NST

VALVE SEATS

BY

PEEN

I

NG AREA

BE-

VALV

€

SEAT

FIGURE

69.

PEENING VALVE SEAT AREA

SPR

I

NG

-WASHER

Face each new seat to a 45 degree angle and width of

approximately 3/64-inch. The finished seat face

should contact the approximate center of the valve

face. Use Prussion Blue on each valve face to check

this. Make corrections to the seat, not the valve face.

Check the valve springs on an accurate compression

scale. Replace any spring that is weak, cracked or

pitted, or has ends out of square. See

Dimensions and

Clearances

section for valve spring data.

INSTALLATION

1.

Push a new valve stem oil seal onto each intake

valve guide and clamp in place. Then oil the inside

surface of each seal.

Engines

built

before June

1962

had no valve seals.

2. Oil stem of each valve lightly and insert each in its

own guide.

3.

Check each valve for a tight seat with an air

pressure type-tester. If a tester isn’t available,

make pencil marks at intervals on the valve face

and observe if marks rub off uniformly when valve

is rotated part of a turn

in

seat. If the seat isn’t

tight, regrind valves.

4.

Using a valve spring compressor, compress each

valve spring with its spring retainer in place and

insert retainer locks.

Spring retainer should never contact valve stem seal

wnen compressing valve springs.

5.

Coat both sides of head gasket with Permatex

No.

3

(pliable sealer). Install head assembly and

gasket to cylinder block. Tighten head bolts 1 or2

turns.

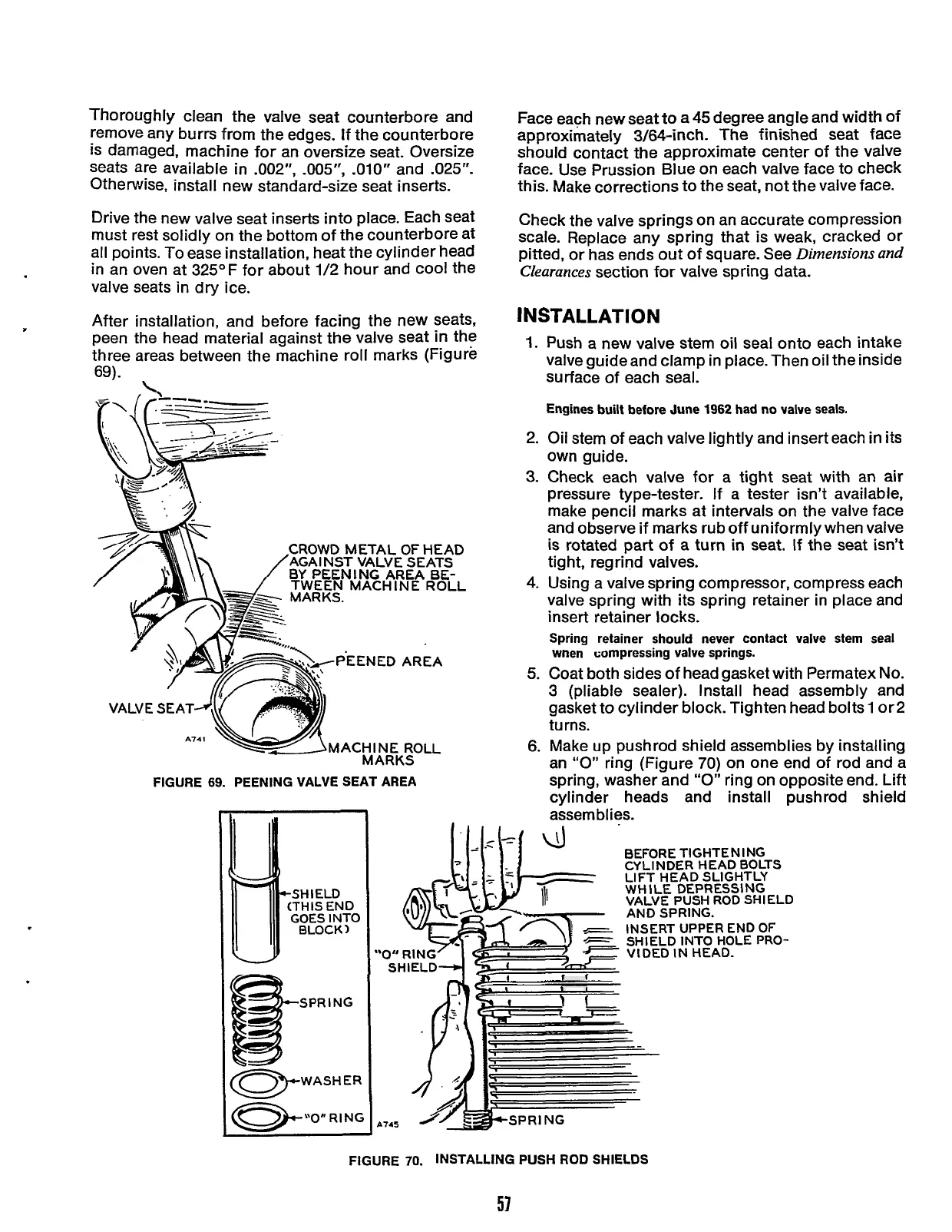

6. Make up pushrod shield assemblies by installing

an

“0”

ring (Figure 70) on one end of rod and a

spring, washer and

“0”

ring on opposite end. Lift

cylinder heads and install pushrod shield

assemblies.

‘I

11

A145

BEFORE TlGHTE

N

I

NG

CYLINDER HEAD BOLTS

LIFT HEAD SLIGHTLY

WHILE DEPRESSING

VALVE PUSH ROD SHIELD

AND SPRING.

INSERT UPPER END

OF

SHIELD INTO HOLE

PRO-

VIDED

IN

HEAD.

FIGURE

70.

INSTALLING PUSH ROD SHIELDS

57

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...