7.

8.

9.

10.

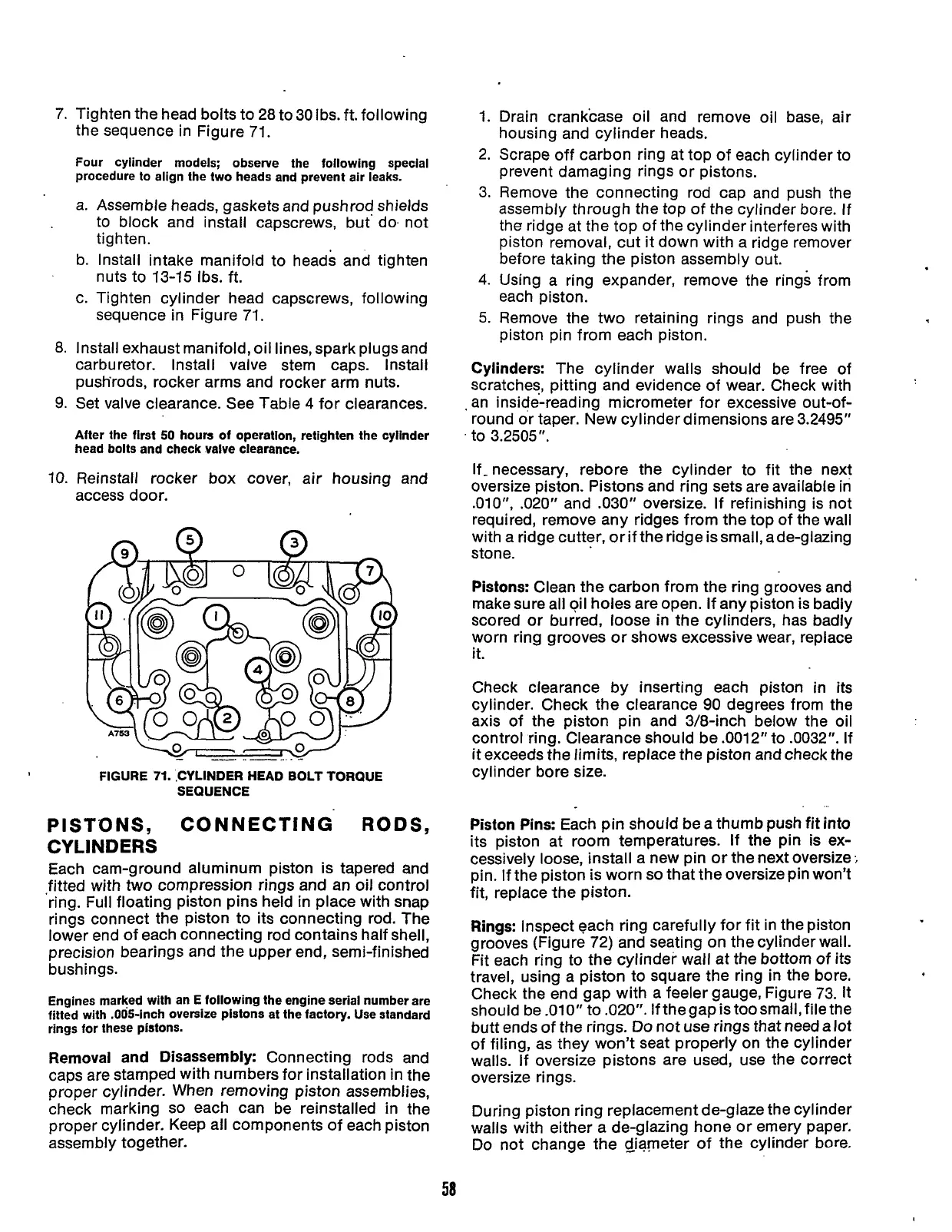

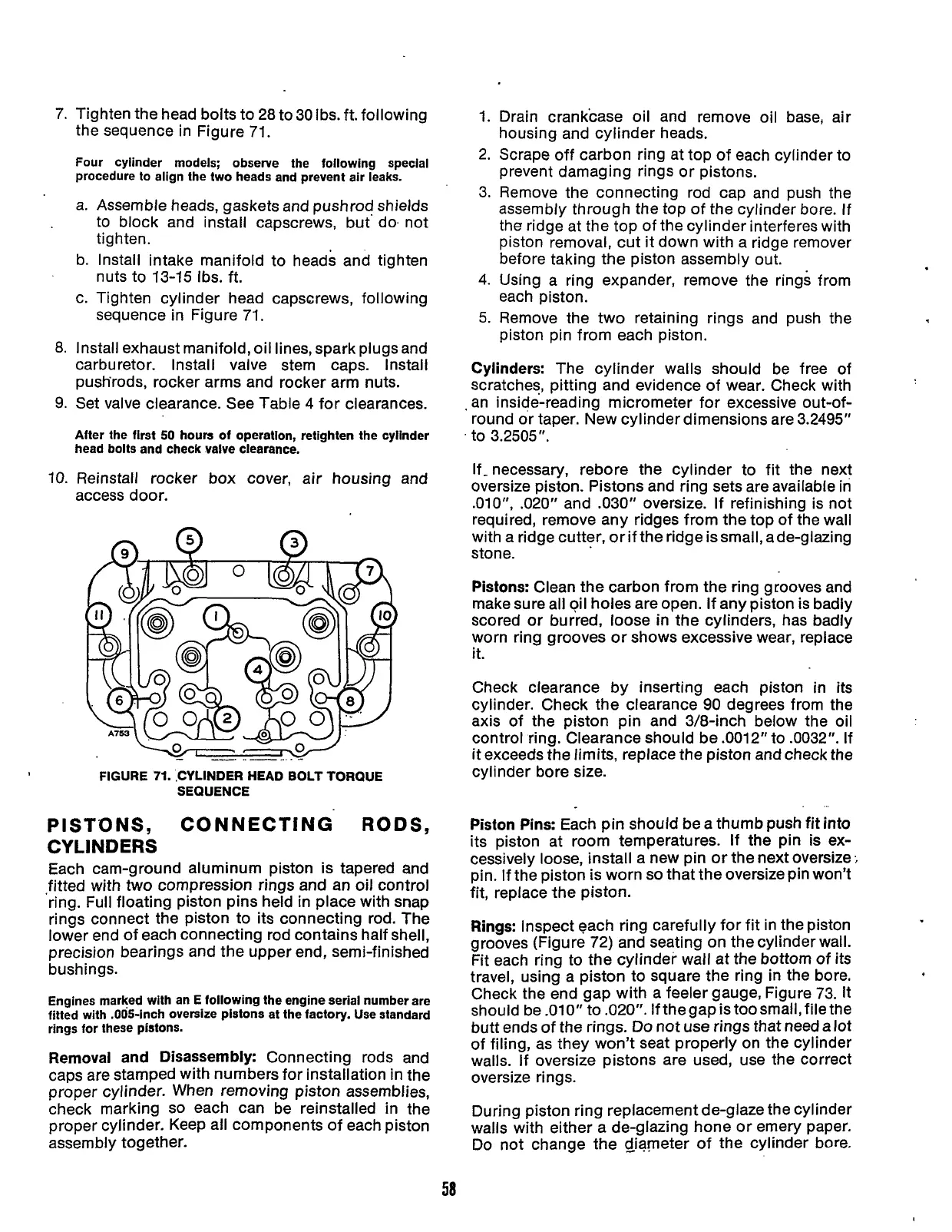

Tighten the head bolts to 28 to 30 Ibs. ft. following

the sequence in Figure 71.

Four cyiinder models; observe the following special

procedure to align the two heads and prevent air leaks.

a.

b.

C.

Assemble heads, gaskets and pushrod shields

to block and install capscrews, but do. not

tighten.

Install intake manifold to heads and tighten

nuts to 13-15 Ibs. ft.

Tighten cylinder head capscrews, following

sequence in Figure

71.

Install exhaust manifold, oil lines, spark plugs and

carburetor. Install valve stem caps. Install

push'rods, rocker arms and rocker arm nuts.

Set valve clearance. See Table 4 for clearances.

After the first

50

hours

of

operation, retighten the cylinder

head bolts and check valve clearance.

Reinstall rocker box cover, air housing and

access door.

-

..

.. . .-

FIGURE

71.

,CYLINDER HEAD BOLT TORQUE

SEQUENCE

PISTONS, CONNECTING

RODS,

CYLINDERS

Each cam-ground aluminum piston is tapered and

fitted with two compression rings and an oil control

'ring. Full floating piston pins held in place with snap

rings connect the piston to its connecting rod. The

lower end of each connecting rod contains half shell,

precision bearings and the upper end, semi-finished

bushings.

Engines marked with an E following the engine serial number are

fitted with .OO!ji-inch Oversize pistons at the factory. Use standard

rings for these pistons.

Removal and Disassembly:

Connecting rods and

caps are stamped with numbers for installation in the

proper cylinder. When removing piston assemblies,

check marking

so

each can be reinstalled in the

proper cylinder. Keep all components of each piston

assembly together.

1.

2.

3.

4.

5.

Drain crankcase oil and remove oil base, air

housing and cylinder heads.

Scrape off carbon ring at top of each cylinder to

prevent damaging rings or pistons.

Remove the connecting rod cap and push the

assembly through the top of the cylinder bore.

If

the ridge at the top of the cylinder interferes with

piston removal, cut it down with a ridge remover

before taking the piston assembly out.

Using a ring expander, remove the rings from

each piston.

Remove the two retaining rings and push the

piston pin from each piston.

Cylinders:

The cylinder walls should be free of

scratches, pitting and evidence of wear. Check with

.

an inside-reading micrometer for excessive out-of-

round or taper. New cylinder dimensions are 3.2495"

.

to 3.2505".

If-necessary, rebore the cylinder to fit the next

oversize piston. Pistons and ring sets are available in

.010",

.020" and .030" oversize.

If

refinishing is not

required, remove any ridges from the top of the wall

with

a

ridge cutter, or if the ridge is small, ade-glazing

stone.

Pistons:

Clean the carbon from the ring grooves and

make sure all oil holes are open. If any piston

is

badly

scored or burred, loose in the cylinders, has badly

worn ring grooves or shows excessive wear, replace

it.

Check clearance by inserting each piston in its

cylinder. Check the clearance

90

degrees from the

axis of the piston pin and 3/8-inch below the oil

control ring. Clearance should be .0012" to .0032".

If

it exceeds the limits, replace the piston and check the

cylinder bore size.

..

Piston Pins:

Each

pin

should be a thumb push fit into

its piston at room temperatures. If the pin

is

ex-

cessively loose, install a new

pin

or the next oversize

;

pin.

If

the piston is worn

so

that the oversize pin won't

fit, replace the piston.

Rings:

Inspect each ring carefully for fit in the piston

grooves (Figure 72) and seating on the cylinder wall.

Fit each ring to the cylinder wall at the bottom of its

travel, using a piston to square the ring in the bore.

Check the end gap with a feeler gauge, Figure 73. It

should be

.010"

to .020". If thegap is toosmall,file the

butt ends of the rings.

Do

not use rings that need

a

lot

of filing, as they won't seat properly on the cylinder

walls.

If

oversize pistons are used, use the correct

oversize rings.

During piston ring replacement de-glaze the cylinder

walls with either a de-glazing hone or emery paper.

Do not change the Giameter of the cylinder bore.

58

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...