6

Location, Mounting and Enclosure

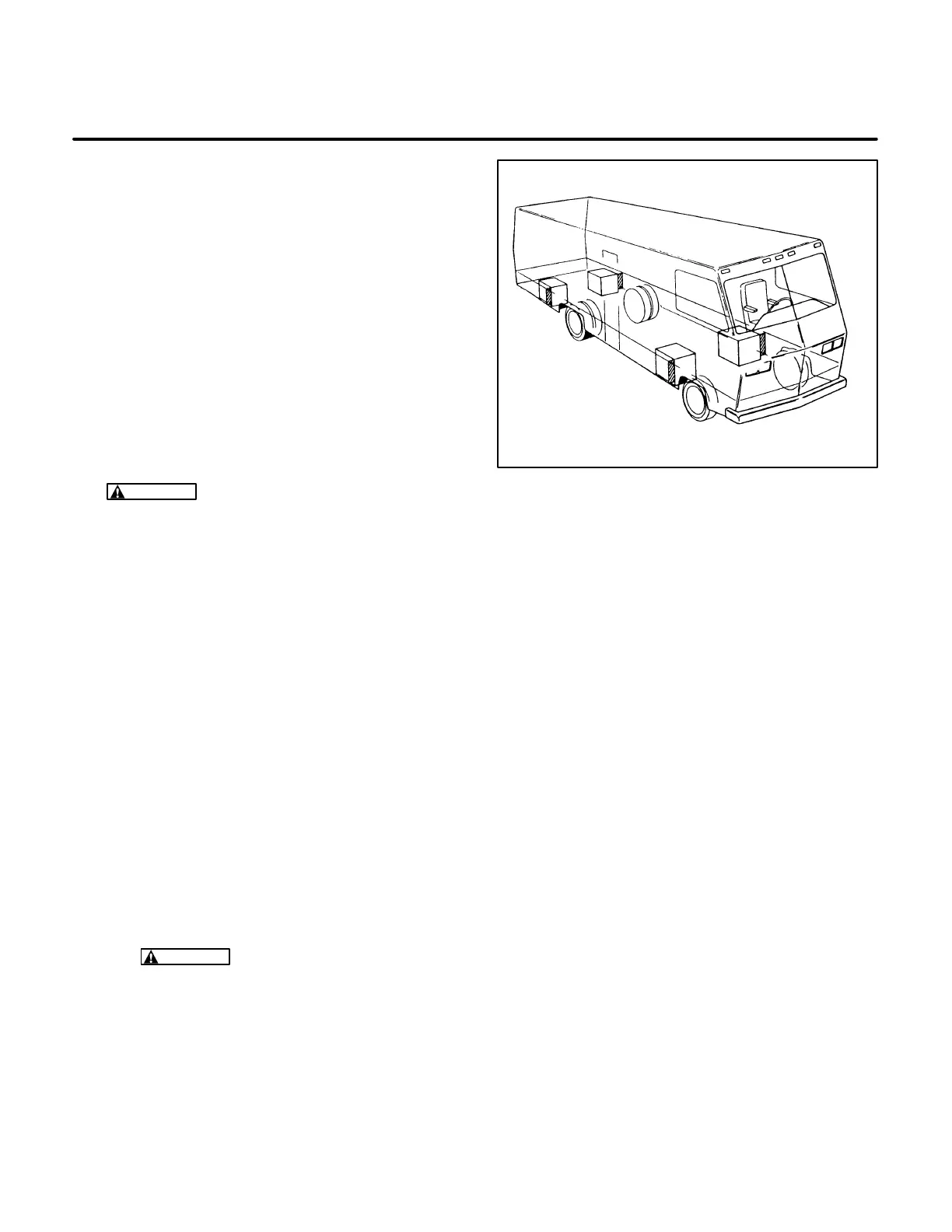

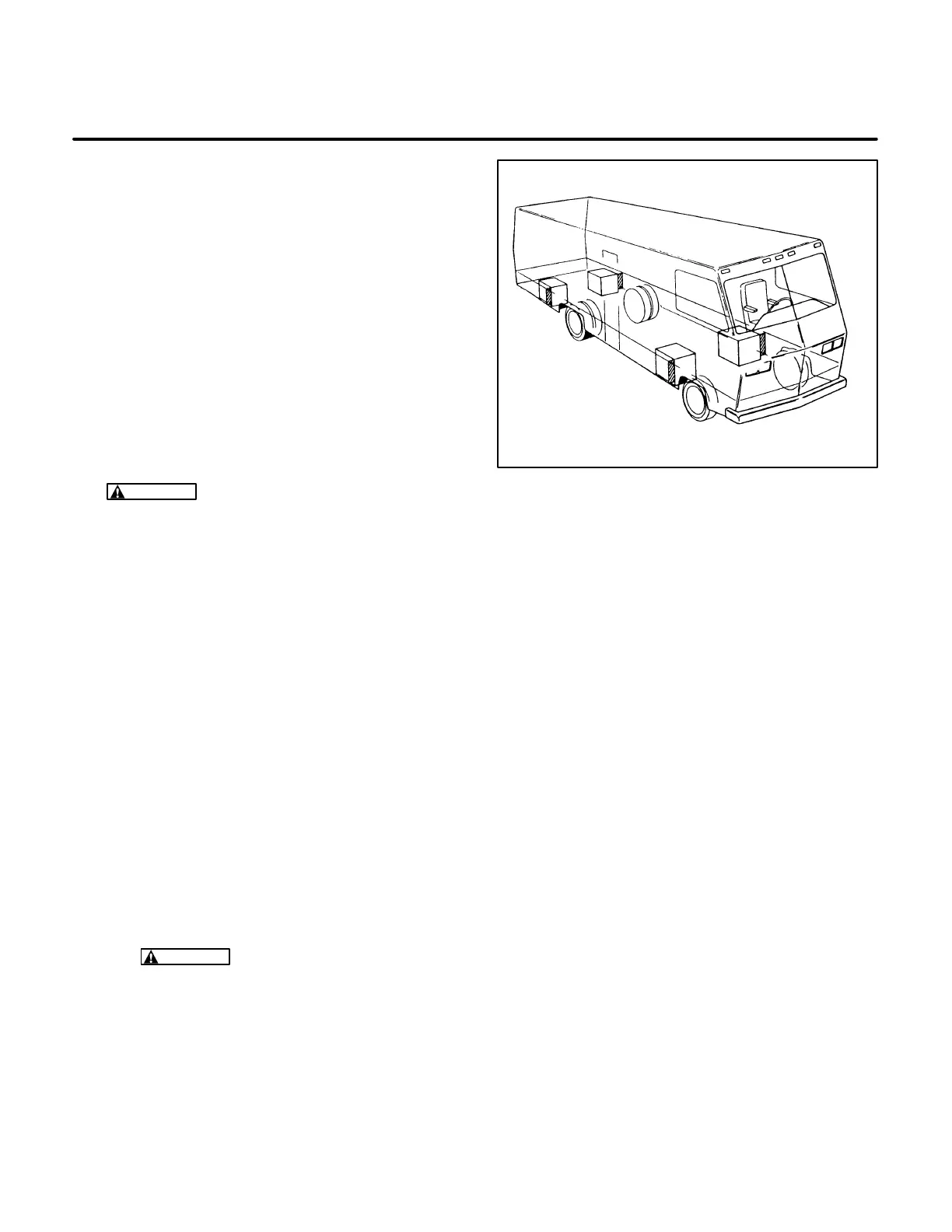

The location, mounting and enclosure of a genset

must be such that mounting is secure, engine ex-

haust and fuel vapors are prevented from entering

the vehicle, rain and road debris are prevented from

entering the genset, and ready access is afforded

for operating the genset and performing periodic

maintenance. See Figure 2 for typical genset loca-

tions.

1. The genset support structure must be able to

resist the dynamic weight of the genset: cyclical

vertical forces of

± 561 lbs (± 3 g) and cyclical

horizontal forces of

± 187 lbs (± 1 g). Secure

the genset with six 5/16-18 NC bolts. The bolts

must protrude at least 1-1/2 threads beyond the

base pan weld nuts but not more than 1/2 inch

(13 mm), to avoid interference.

WARNING

The genset can fall from the ve-

hicle if the supporting structure is weak and

cause severe personal injury or death. De-

sign the structure carefully, follow applica-

ble mounting kit instructions and torque

mounting bolts properly.

2. The genset can be mounted on or below the ve-

hicle floor:

A. Below-Floor Mounting - Use one of the

mounting kits available from Onan

(Page 22, 23 or 24). Follow the instruc-

tions in the kit and use Underfloor Tem-

plate 539-1535 to locate the assembly. A

plywood or particle board floor must be re-

inforced with steel to resist the dynamic

weight of the genset (Item 1). Do not

mount the genset within the approach or

departure angles of the vehicle or below

the axle line (Figure 7). If the floor is of

combustible material such as wood, install

a barrier of 26 gauge galvanized steel or

equivalent between the floor and the gen-

set.

WARNING

FIRE IS DEADLY! Install a

fire-resistive barrier of approved mate-

rials between the floor and the genset.

FIGURE 2. TYPICAL GENSET LOCATIONS

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...