C.

Tighten cylinder head bolts in sequence

shown in Figure 103 to

25-30

ft.-lb. (34-41

Nm).

D.

Tighten cylinder head bolts in samesequence

to

44-46

ft.4

b.

(60-62

N

m) .

E.

After

60

seconds, retighten cylinder head

bolts in sequence to 44-46

ft.-lb.

(60-62

Nm).

This step compensates for the compress of

the

cylinder gasket.

Install intake manifold, nozzles, glow plugs, and

oil lines.

Install valve stem cap.

Install push rods, rocker arms, and rocker arm

nuts.

Set valve clearance. See Figure

101.

IMPORTANT: Afler the first

50

hours of operation, retighten

the cylinder head bolts and check valve clearance.

VALVE ROTATOR CLEARANCE

Both the intake and the exhaust valves on all Onan

J

Series engines are equipped with release-type valve

rotators. The cap covering each valve

tip

releases

keeper tension as thevalve is pushed

off

itsseat.This

allows the valve to float

in

its guide. Engine vibration

and cylinder air flow cause the valve to rotate while

floating.

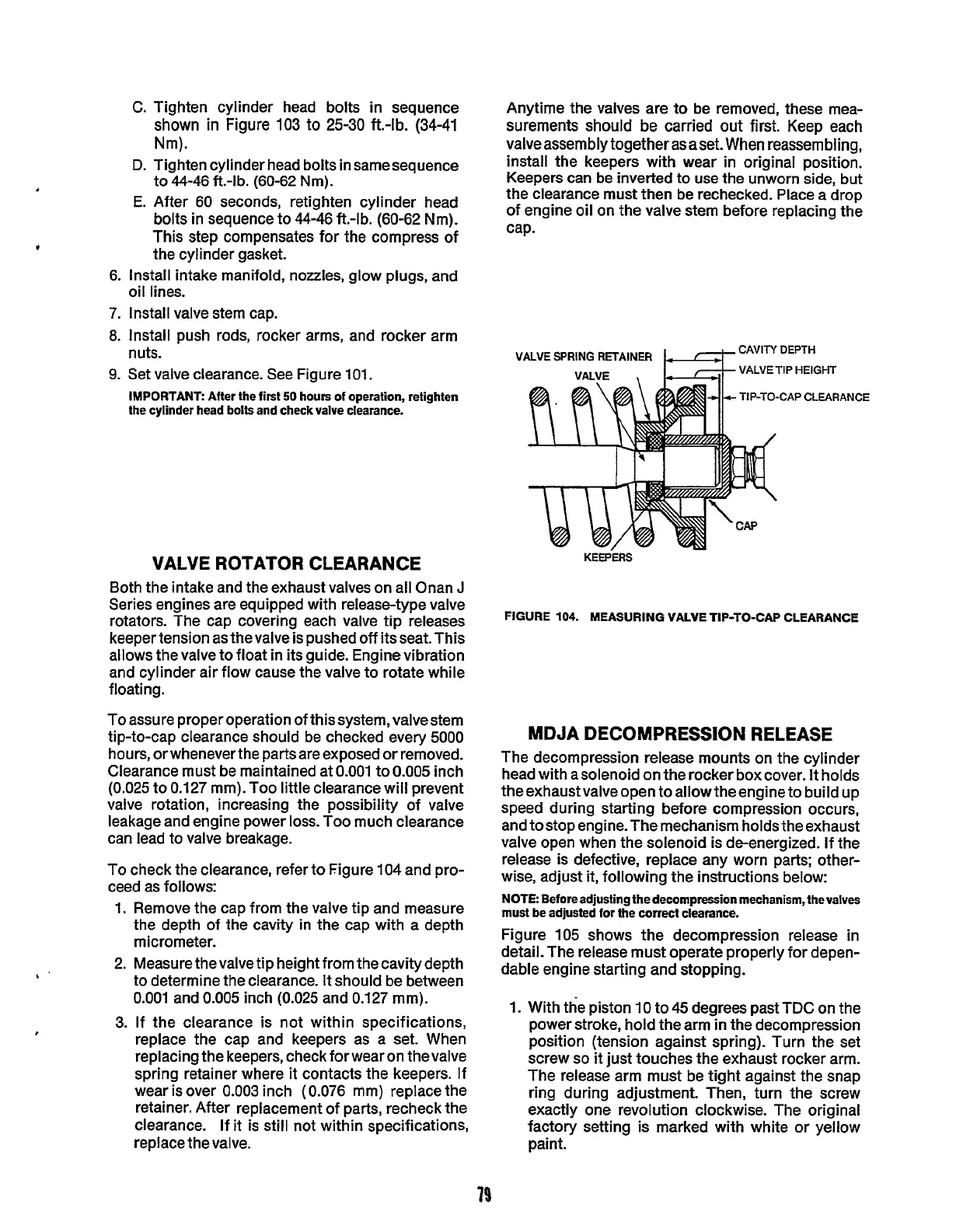

To assure proper operation of thissystem,valvestem

tip-to-cap clearance should be checked every

5000

hours, or whenever the parts are exposed or removed.

Clearance must be maintained at

0.001

to

0.005

inch

(0.025 to 0.127 mm). Too

little

clearance will prevent

valve rotation, increasing the possibility of valve

leakage and engine power

loss.

Too much clearance

can lead to valve breakage.

To

check the clearance, refer to Figure

104

and pro-

ceed as follows:

1. Remove the cap from the valve tip and measure

the depth of the cavity in the cap with a depth

micrometer.

2. Measure thevalve tip height from thecavity depth

to determine the clearance. It should be between

0.001 and

0.005

inch

(0.025

and 0.127 mm).

3.

If the clearance is not within specifications,

replace the cap and keepers as a set. When

replacing the keepers, check for wear on thevalve

spring retainer where it contacts the keepers. If

wear is over

0.003 inch (0.076 mm) replace the

retainer. After replacement of parts, recheck the

clearance. If it is still not within specifications,

replace the valve.

Anytime the valves are to be removed, these mea-

surements should be carried out first. Keep each

valveassembly together as aset.

When

reassembling,

install the keepers with wear in original position.

Keepers can be inverted to use the unworn side, but

the clearance must then be rechecked. Place a drop

of engine oil on the valve stem before replacing the

cap.

VALVE

SPRING

RETAINER

DEPTH

HEIGHT

LP

CLEARANCE

FIGURE

104.

MEASURING VALVE TIP-TO-CAP CLEARANCE

MDJA DECOMPRESSION RELEASE

The decompression release mounts on the cylinder

head with a solenoid on the rocker box cover.

It

holds

the exhaust valve open to allow the engine to build up

speed during starting before compression occurs,

and tostop engine.The mechanism holds the exhaust

valve open when the solenoid is de-energized. If the

release is defective, replace any worn parts; other-

wise, adjust

it,

following the instructions below:

NOTE

Beforeadjusting thedecompression mechanism, thevalves

must be adjusted

for

the

correct

clearance.

Figure 105 shows the decompression release in

detail. The release must operate properly for depen-

dable engine starting and stopping.

1.

With the piston

10

to

45

degrees past TDC on the

power stroke, hold the arm

in

the decompression

position (tension against spring). Turn the set

screw

so

it

just touches the exhaust rocker arm.

The release arm must be tight against the snap

ring during adjustment. Then, turn the screw

exactly one revolution clockwise. The original

factory setting is marked with white or yellow

paint.

79

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...